News

-

Core equipment configuration and process optimization of high-capacity sand and gravel production line

Read moreI. Background on Modern Construction Sand and Gravel Demand With the acceleration of global urbanization, my country’s construction industry’s annual consumption of sand and gravel aggregates is expected to exceed 20 billion tons by 2025, with the proportion of manufactured sand increasing from 65% in 2020 to 82% in 2025. Taking the Shenzhen Qianhai Free…

-

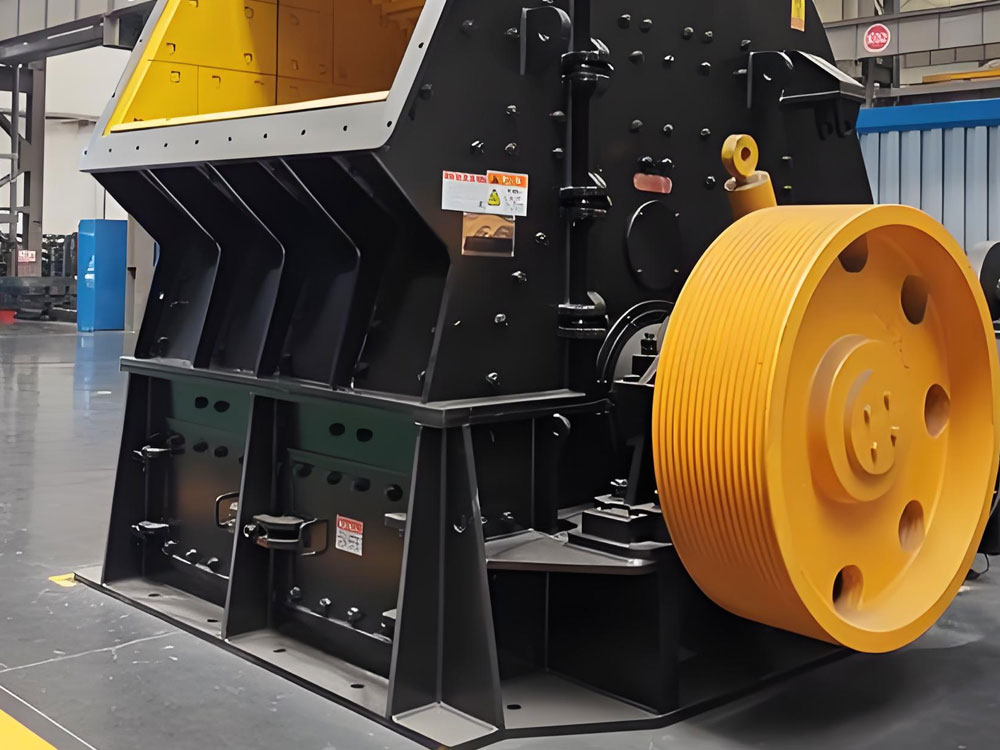

Mobile and Stationary Crushing Equipment: Key Technologies for Efficient Construction Waste Processing

Read moreConstruction waste crushing and sand-making machines come in various models, with processing capacities varying significantly based on equipment type and technical specifications. Below is an analysis of common models and their processing capabilities: I. Fixed Crushing and Sand-Making Machine Processing Capacity Jaw Crusher (Primary Crushing) Processing Capacity: Typically 100-1500 tons per hour, depending on model…

-

Applications and Crushing Process Flow of Potassium Feldspar

Read moreI. Basic Information on Potassium Feldspar Potassium feldspar (chemical formula K₂Al₂Si₆O₁₆), as an important nonmetallic mineral, is widely distributed in nature. It possesses unique crystal structures and physicochemical properties, making it indispensable in numerous industrial applications. Visually, potassium feldspar typically appears in various hues such as flesh-pink, white, or gray, with diverse crystal forms including…

-

Detailed Process of Hard Materials from Primary Crushing to Final Product

Read moreThe following provides a comprehensive analysis of the entire process and key technical points for crushing and sand-making production lines handling hard materials such as pebbles and granite, systematically organized based on industry practices and equipment performance parameters: I. Raw Material Characteristics and Equipment Selection Material Characteristic Analysis Pebbles Physical Properties: Mohs hardness 6-7 (close…

-

Detailed Explanation of Crushing Equipment and Processes Required for Sand and Gravel Aggregate Production Lines

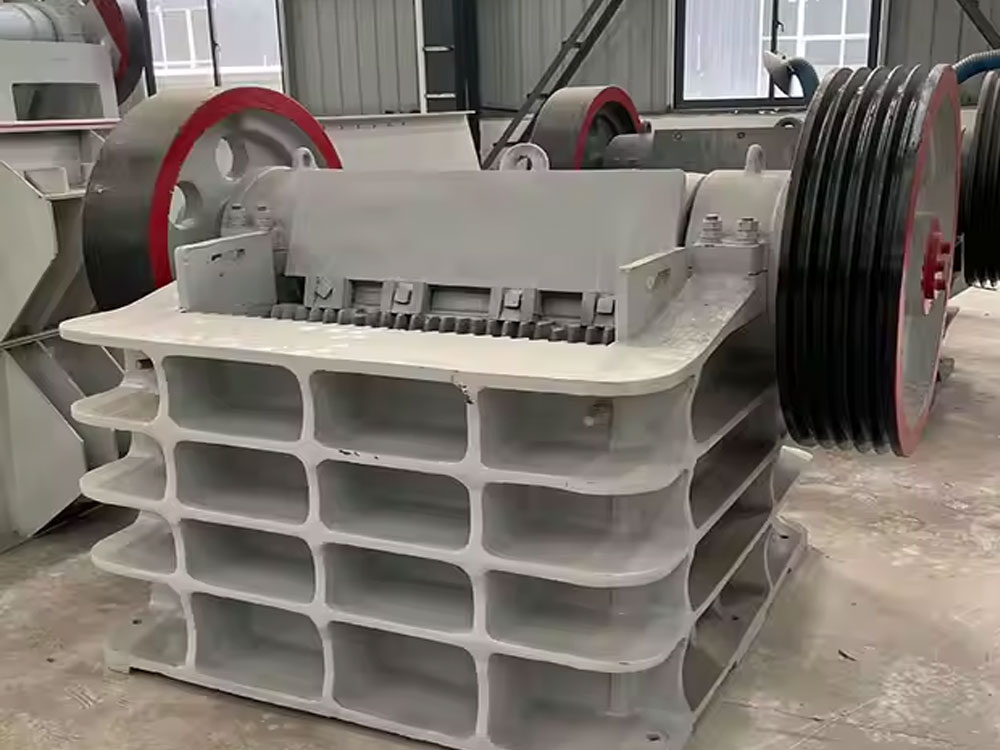

Read moreIn the field of sand and gravel aggregate production, the proper selection of crushing equipment and processes is crucial for producing high-quality, specification-compliant sand and gravel products. The following details the crushing equipment and associated processes required for each stage of a sand and gravel aggregate production line. I. Primary Crushing Stage Jaw Crusher The…

-

How to Select Suitable Aggregate Production Line Equipment?

Read moreIn infrastructure construction such as buildings and roads, sand and gravel aggregates are indispensable foundational materials. An efficient, stable, and production-demand-aligned aggregate production line plays a crucial role in ensuring aggregate quality, output, and cost control. Below, we detail key considerations for making the right choice. I. Define Production Requirements Output Requirements First, determine the…

-

Detailed Explanation and Configuration Optimization of Complete Crushing and Sand-Making Production Line Equipment

Read moreThe crushing and sand-making production line serves as the core system for aggregate production, requiring equipment configuration that balances raw material characteristics, production capacity requirements, environmental standards, and economic viability. The following analysis explores four dimensions: core equipment, mobile solutions, typical configurations, and material compatibility, supplemented by key technical parameters and case data. I. Core…

-

Which types of rock are suitable for producing manufactured sand? How should a manufactured sand production line be configured?

Read moreThe raw materials for manufactured sand are widely sourced, encompassing three main categories: natural rock, industrial waste residue, and construction debris. Specific application scenarios and advantages are as follows: Granite Characteristics: High quartz content (up to 60% or more), low sulfide content, compressive strength of 120-200 MPa, well-rounded particle shape, and reasonable gradation. Applications: Suitable…

-

Detailed Process Flow of Granite Sand Production Site

Read moreI. Process Flow Overview Granite sand production sites typically employ a multi-stage crushing and screening process. Through scientifically optimized equipment configuration and process parameter control, this approach achieves efficient, high-quality manufactured sand production. The process encompasses critical stages including primary crushing, secondary/tertiary crushing, sand shaping, washing, and dewatering. Each stage is seamlessly integrated to collectively…

-

Iron ore project, HPT crusher boosts production capacity

Read moreIn the resource-intensive iron ore processing industry, equipment performance directly determines production efficiency and economic benefits. As a representative of third-generation intelligent crushing equipment, the HPT multi-cylinder hydraulic cone crusher is reshaping the production paradigm of iron ore crushing through multi-dimensional technological innovation. The following is an in-depth analysis from three perspectives: technical principles, application…