Granite crushing line design solutions

A granite crushing line is usually determined by several factors: The raw material was crushed. Hardness, percentage of silicon, moisture percentage of raw material. The average size of raw materials enter into crushing system. Required product size, proportion and their usage. The load per hour of crushing production line.

For granite crushing production line design solutions: 30-50tph, 50-80tph, 80-120tph, 120-200tph, 200-300tph, 300-400tph, and 400-500tph. Here we recommend three suggestions:

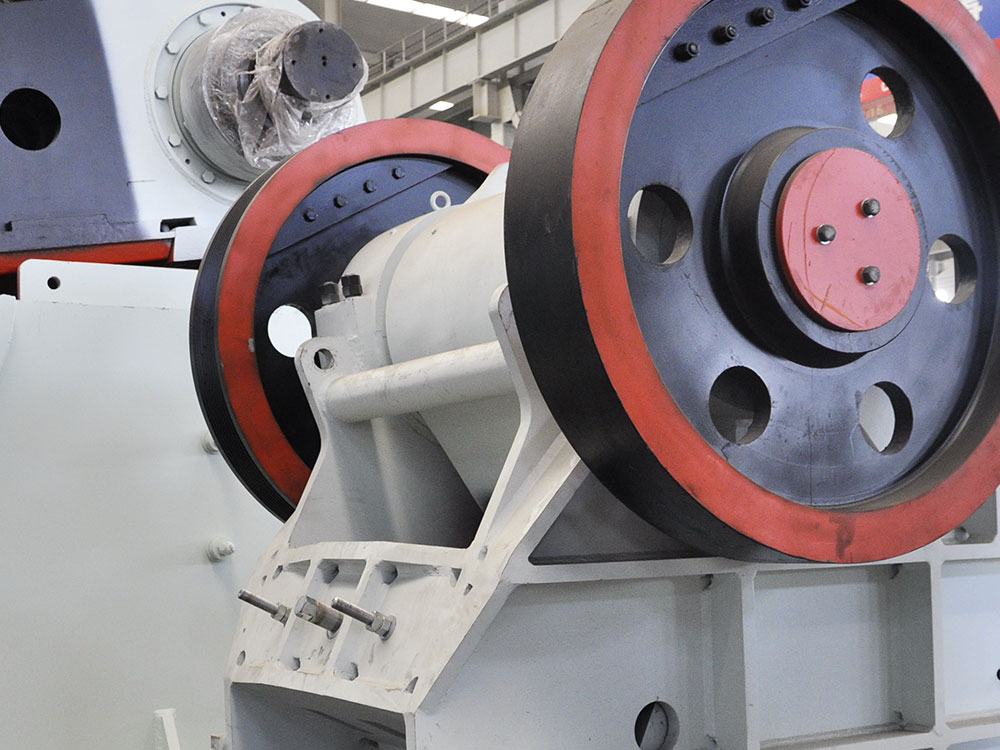

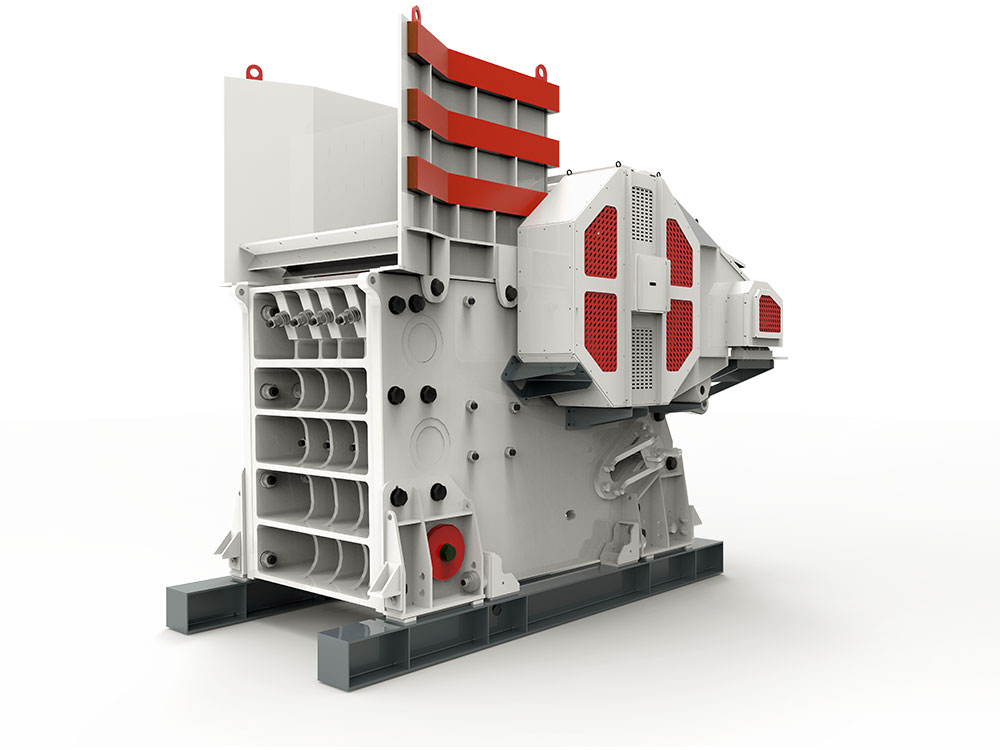

(1) Vibrating feeder + primary jaw crusher and cone crusher + composite crusher (optional) + vibrating screen + belt conveyor system + control system

(2) Vibrating feeder + original jaw crusher and impact crusher + vibrating screen and belt conveyor system + control system

(3) Vibrating feeder + original jaw crusher and jaw crusher + fineness impact crusher (optional) + vibrating screen + belt conveyor system + control system

The main difference in these suggestions is the secondary crusher: adopt impact crusher (hammer crushing principle), or use the fine jaw crusher (plate pressure principle), or composite cone crusher (plate pressure principle).