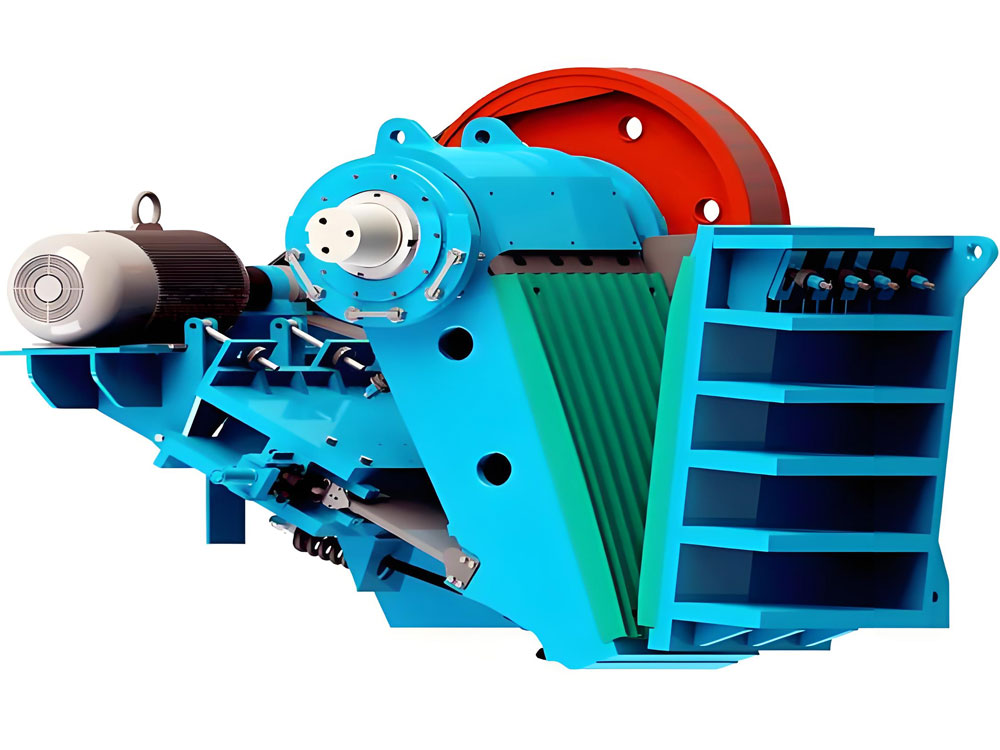

aggregate rock crushers operation methods

Aggregate and rock crushing operations involve the handling and processing of nonmetallic mineral products for the construction industries. Nonmetallic mineral products are quarried or mined and are then transported to the processing plant for further classification and/or further size reduction. In addition, some recycled aggregate products (such as concrete and asphaltic concrete) are also processed in these plants.

Operation of any type of aggregate and rock crushing process may be subject to some or all of the following rules and regulations.

1. When Impact Crusher is running, the staff can not stand in the inertial force within the scope of the action line, and the electrical switch installation should avoid this location.

2. When Impact Crusher is running, it is strictly prohibited to open the inspection door to observe the situation inside, make any adjustments , cleaning and maintenance work to avoid danger.

3. It is strictly prohibited to throw materials that can not be broken into to avoid damage to the machine.

4. We should be cut off the power before overhauling Impact Crusher.

5. When the machine is running, it is strictly prohibited to the machine work overload.

6. The electrical equipment should be grounded, wire should be reliable and insulation.

The processing of sand and gravel for a specific market involves the use of different combinations of washers, screens, and classifiers to segregate particle sizes; crushers to reduce oversized material; and storage and loading facilities. The various types of equipment used in these plants include: hoppers, belt conveyors, screens, scrubbers, pumps, storage bins, crushers, jigs, screws, front end loaders, scrapers, trucks, engines, and generators.