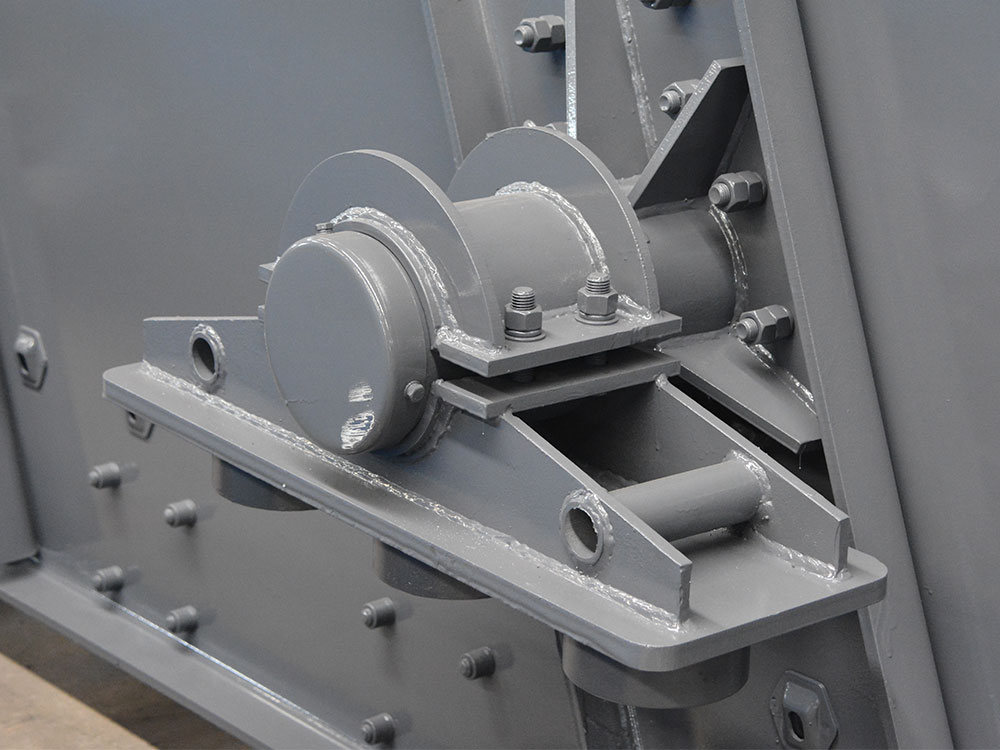

Jaw Crusher in iron ore mining process

The common iron ore mining equipment are jaw crusher, cone crusher, hammer crusher, ball mill, fine grinding, etc. Often workers prefer to choose a metallurgical plant which possesses a complete iron ore crusher plant. So far, the most popular iron ore production line combines two jaw crushers with sand making machine, and later the material is sent for magnetic separation and grinded into the ball mill.

Iron is the most frequently-used metal, of which the iron ore is the key factor with 95% of the using metal. Iron is mainly used in structural engineering application and maritime affairs use, car industry and common industry.

It is universal in the world for the rock which is rich in iron. The classification & features of iron makes iron variety in the rocks which constitutes the crustal. There are more than 300 kinds of iron ore which have been already known clearly but only 20 kinds can be taken as the raw material for puddling. According to its shape iron ore can be classified as hematite, magnetite, limonite, siderite, etc.

Liming Heavy Industry manufactures several series iron ore crusher, which is suitable for iron ore especially the mobile crusher and cone crusher. Iron ore cone crusher is a high efficiency crusher with the advantage of high output and low safeguard. And the long head type cone designing provides more crushing power for iron ore.

Mobile iron ore crusher is based on the Liming’s traditional design, and completely adopts every condition to crush the iron ore, which has eliminated the obstacle of position, environment and foundation architecture so the simple, high efficiency and low costing equipment is developed by Liming. Our iron ore mobile crusher includes cone crusher, mobile crusher, impact crusher series plant, jaw crusher series plant and crawler type mobile crusher plant. This series crusher provides customers the simple, high efficiency and low cost machine genuinely.