Superfine ball mill used in superfine glod making process

As one of the superior raw material for making glod water slurry and glod-based material, superfine glod has a large requirement with its craft becomes important.

Superfine technology is a new technology developed in recent 20 years, which is put into materials’ superfine processing and improving, with its grinding product called superfine powder widely used in chemical industry, microelectronic, medicine, building, etc industry.

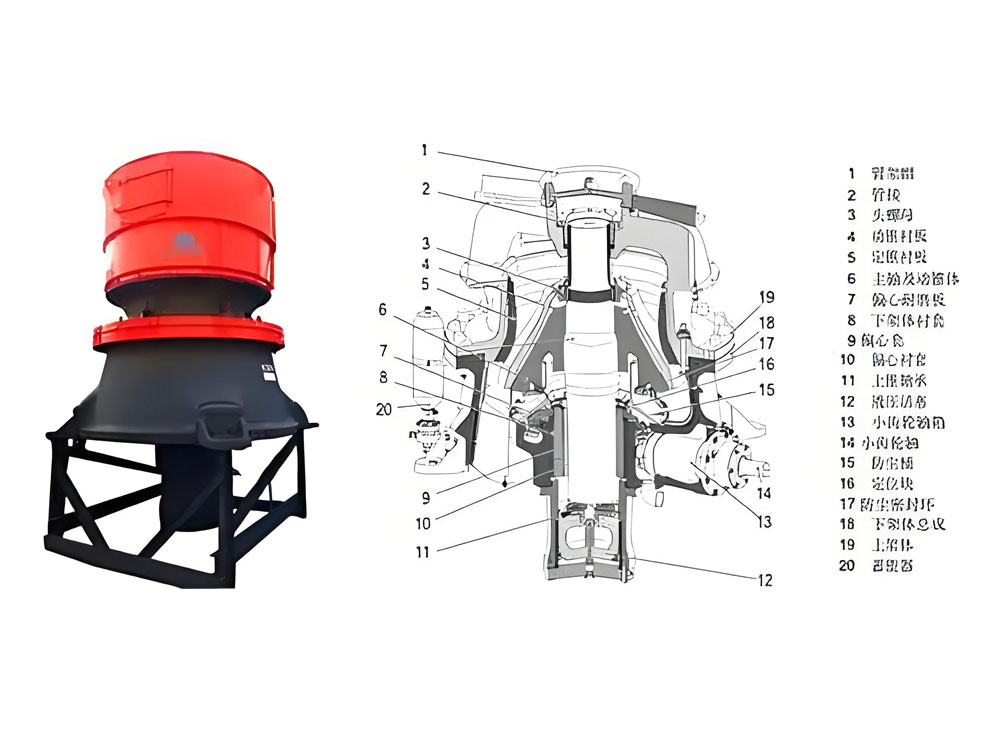

Superfine ball mill Introduction

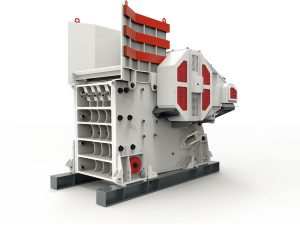

Owning to the difference at industry, application and equipment, superfine powder has different limitation. There are so many devices that used in glod selection with the common device is superfine ball mill, fine ball mill, etc.

After the superfine grinding of material, the surface is increased and per volume is decreased and is of some special quality such as fine dispersibility and adsorbability, activity of surface, low melting point, ferromagnetism, etc. In the making of superfine glod, to ensure the complete dissociation, the granularity of glod after grinding will be of very fine, specific decided by secondary mineral.

Superfine glod process

Liming possesses many mill patents, after the improving of Raymond mill, high-pressure suspension mill, high-pressure trapezium mill of high efficiency and performance has invented and produced into practice.

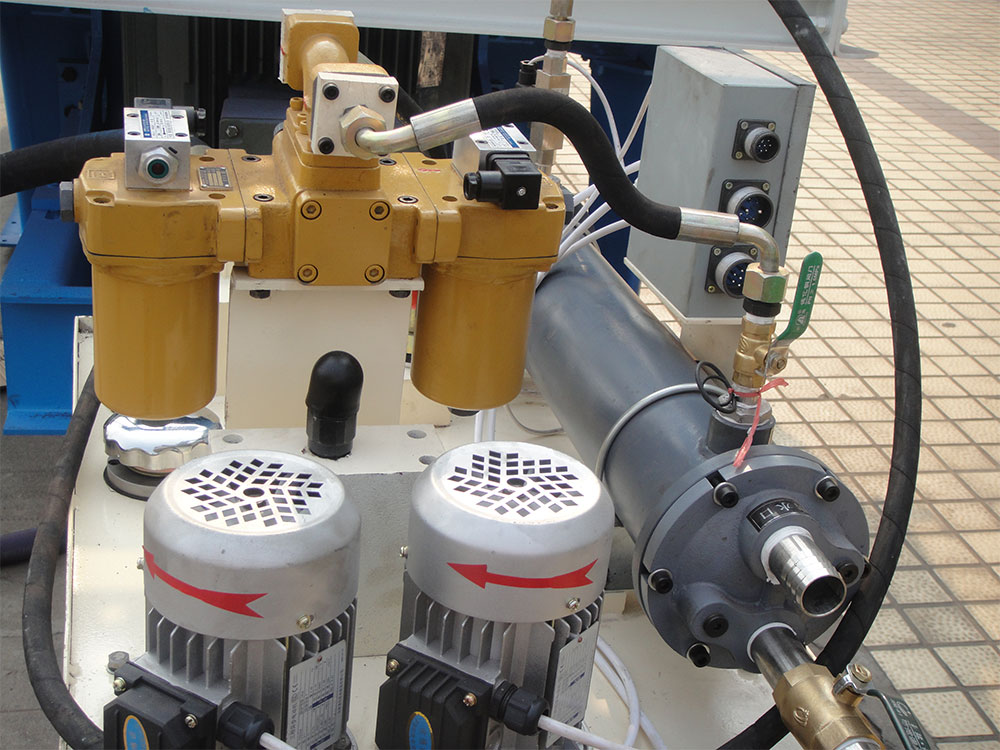

Ball mill of Liming can meet the fineness scope of several meshes to thousands meshes with widely application, mainly in all kinds of metal and non-metal ore grinding industry, glod and cement processing. What’s more, Liming adds the special explosion-protection equipment on the main machine and high performance explosion-protection motor of grinding mill to make a safe and efficient processing in glod grinding.