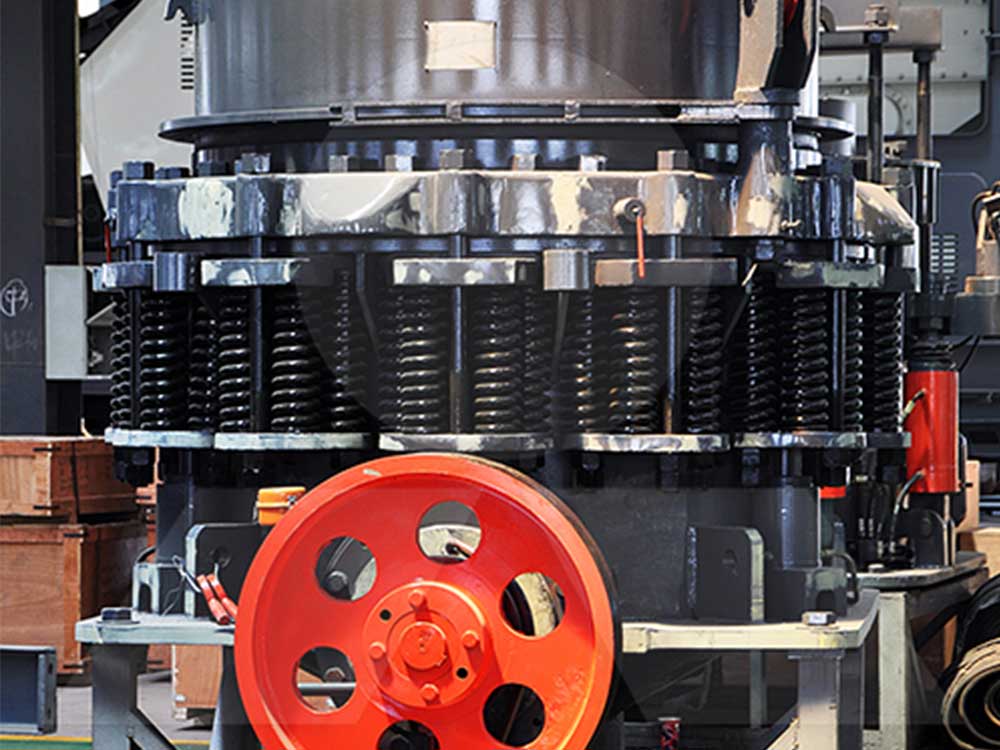

How to prevent the emergence of cone crusher shaft fracture failure

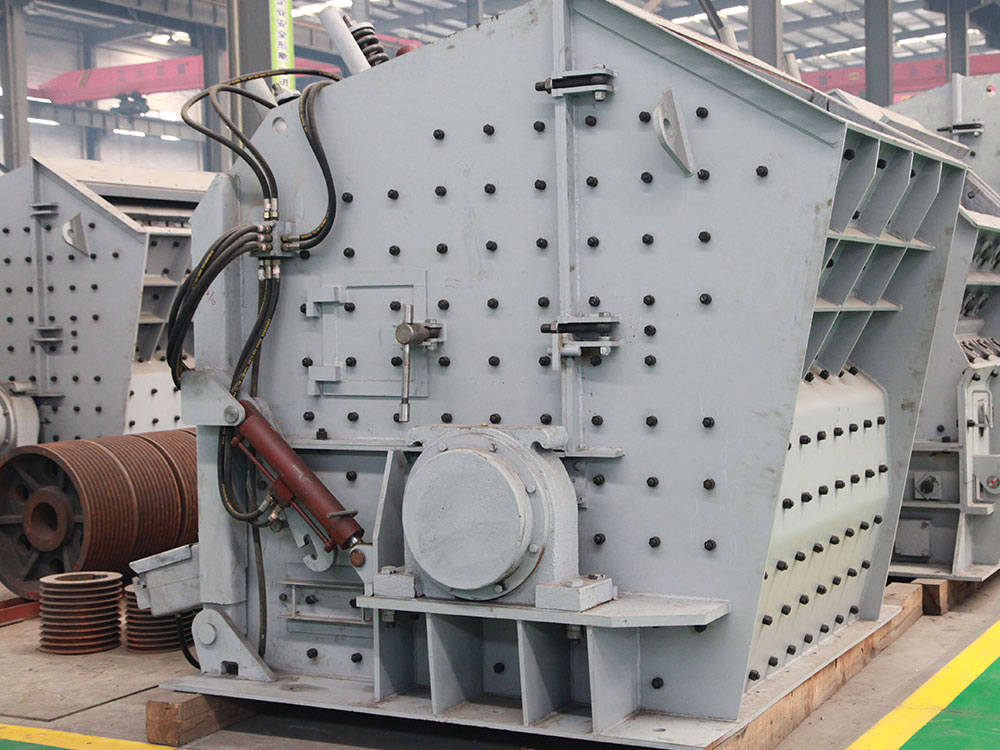

Crusher is widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industry and many other industries. Cone crusher crushing ratio, high efficiency, low energy consumption, uniform particle size, suitable for secondary and tertiary crushing of various ores, rocks. In the course of their work, the spindle fracture is a common fault that would seriously affect the normal operation of the crusher. Therefore, we should take effective measures to avoid the failure.

Cone crusher shaft fracture causes:

1. Due to the unique working characteristics of the crusher, the impact of long-term bear frequent spindle prone to fatigue damage.

2. The machine is running feed too much, causing the equipment overloaded.

3. In the process of mining the ore transport, often mixed with some scrap metal objects, these objects through the upper end of the electromagnet tape, since the electromagnet adsorption capacity is weak, plus the metal manganese-containing material properties, the electromagnet can not be ruled out causing these materials mixed in with the mud ore into the crusher, resulting in excessive iron frequent, causing frequent impact on the spindle and other components. The spindle fatigue damage is the main reason for breaking the spindle.

Precaution:

1. On-site maintenance personnel during maintenance operations, to deal with the replacement parts for recycling waste down, into the specified location, is strictly prohibited all kinds of metal waste thrown away to the ore.

2. Maintenance personnel seized equipment, strict adherence to rules, to avoid maintenance tools and debris left in the device.

3. To improve the ability of metal detectors to detect and exclude metals.

4. Increase efforts on materials inspection, found that foreign matter must be promptly picked.

5. When they find the current, sound or other abnormal conditions to the timely processing, reporting, prevent the accident.

6. Regular use of ultrasound and other equipment for spindles force components testing, in order to understand the actual state of the device.

7. Strengthening the training of workers, improve the practical operation level workers, strengthen equipment maintenance, ensure that the equipment is in good technical condition.

8. For key equipment components and do its inventory of spare parts procurement, after the exceptional circumstances in order to avoid causing the whole system shutdown.