Potassium feldspar ore dressing process step, a production line

Potash feldspar in China are very rich, and the distribution range is wide, such as fujian, sichuan, anhui, shanxi, Inner Mongolia, xinjiang and other places, its reserves of about 7.914 billion tons. As a result, the potash feldspar ore dressing process got the attention of many people. Potassium feldspar ore dressing process flow step explanation will be divided into the following eight steps.

1. Broken: first, use large pieces of rock crushing jaw crusher.

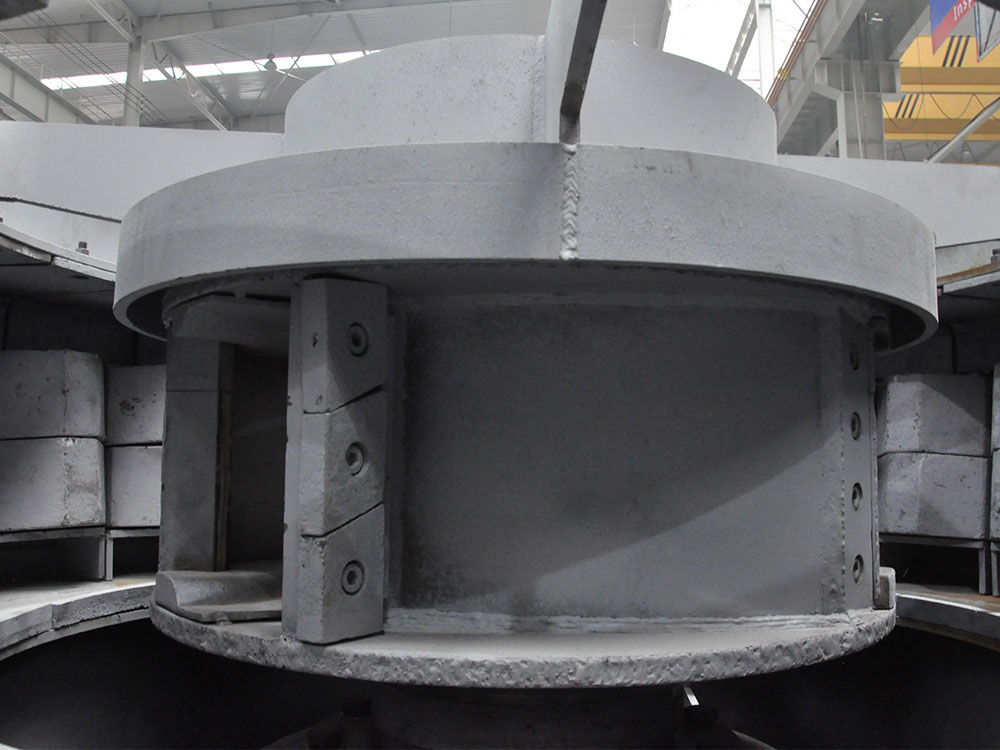

2. The ball mill: the broken stones after use ball mill for ball mill.

3. Wash mud: 20-200 intention fine powder material into the spiral chute, separation separation, select the sediment;

4. Sorting: will remove sediment after by sorting the material into the table, wash the ferric oxide;

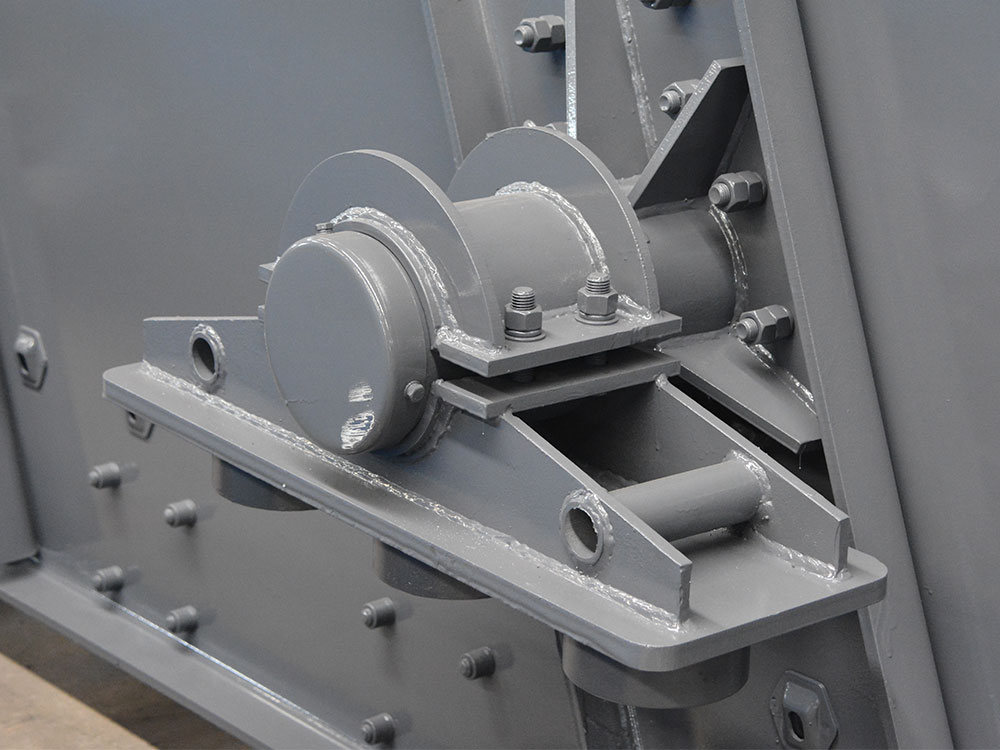

5. Select: will remove ferric oxide materials into 1024 strong magnetic separator were selected, select, mica iron material, then put the material into 1018 x type 2 general magnetic separator, sorting again;

(note: the use of magnetic separator in potassium feldspar iron does not fit all potash feldspar mines, the current flotation technology has been widely used.)

6. Purification: chose by heavy material into high frequency vibrating screen and universal suffrage, remove the ferric oxide in the powder and ferroferric oxide, get potassium feldspar powder;

7. Acid powder: using sulfuric acid as acid lotion, according to the concentration of acid and iron content of potassium feldspar powder blending, in sulfuric acid concentration concluded that, under the condition of the iron content of potassium feldspar powder and participate

Component is proportional to the sulfate, pickled completely remove ferric oxide and ferroferric oxide, separation of ferrous sulfate solution, get potassium feldspar powder;

8. Screening of potassium feldspar powder: potassium feldspar powder into 20-200 mesh sieve sieve, sieve the content for the iron content of less than 0.24% of the products.

The pursuit of excellence and innovation of the Liming team,will continue to use high-quality products, professional skills, sincere services to help customers create more revenue, with practical actions to promote the construction of the world's machinery manufacturing industry. If you want to field trips to our company and production base, You can send mail to tell us your needs or leave your contact information, we will contact you shortly, Liming happy to serve you!