Micro powder mill

Micro powder mill profile: in kaolin, limestone, calcite, talc, barite and other materials, marble, in the production of crushing mill is indispensable equipment, for some materials with higher grinding fineness, micro powder mill become the preferred.

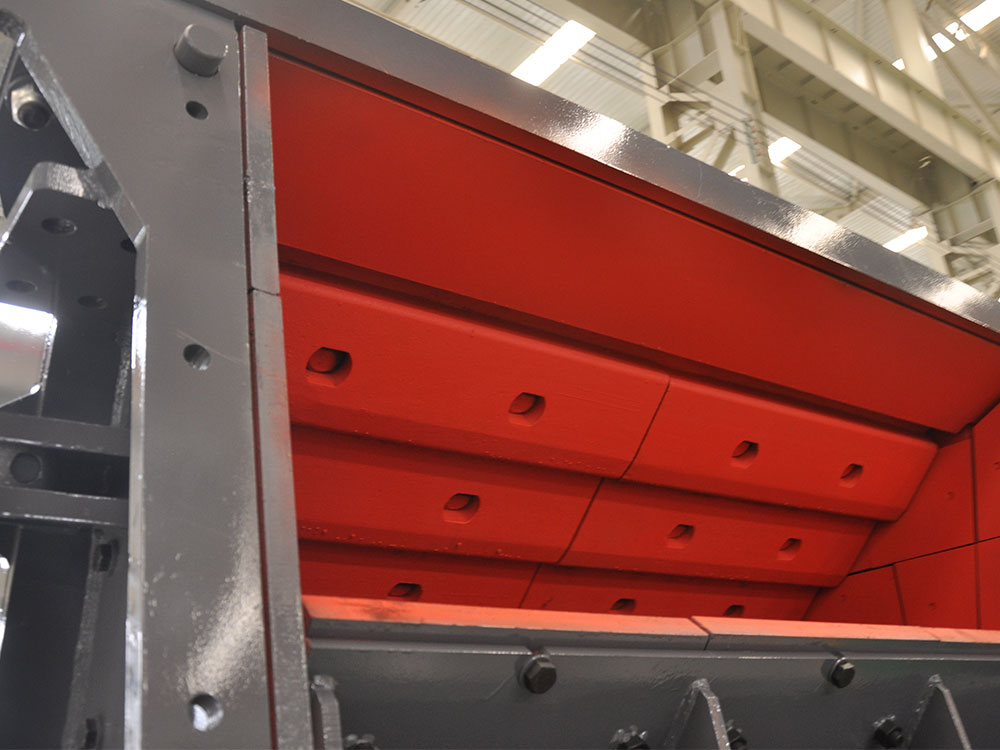

Powder machine working principle: this machine work with screw conveyor to send material feeding to rotate for the middle of the mill, the effect of material by centrifugal force, from the central week moving outward.In mill outer raceway, install several rollers (2 ~ 4).Material between the roller and roll mill, squeezed and ground exfoliation and shattered, and then continue week moving outward.Mill is surrounded by air nozzle, air (it could be a hot gas or kiln gas) through a nozzle into the mill chamber, cyclotron rise, will be after crushing of the material to the top of the classifier to choose powder.Massive particles, and the new feeding material mix together, again returned to the mill, to accept.Selected fine fine powder particles after a classifier rotor central, away from mill.Metal inclusion in rising air drop, such as the inclusion exhaust outlet.

If you want to know more product characteristics of micro powder mill, can seek advice website customer service.