Concrete Crusher for Demolition: 5 Key Factors to Choose the Right Machine

Demolition projects generate massive amounts of concrete waste, and a concrete crusher for demolition is the most efficient solution to recycle debris on-site. Whether you're a contractor, demolition specialist, or recycling company, choosing the right crusher can save time, reduce costs, and improve sustainability.

In this guide, we’ll cover:

✔ Types of concrete crushers for demolition

✔ Key features to consider

✔ Benefits of on-site crushing

✔ Top brands and models

✔ Maintenance tips for long-term use

Types of Concrete Crushers for Demolition

Different crushers are designed for specific demolition needs:

A. Jaw Crushers

Best for primary crushing of large concrete slabs.

High crushing force, ideal for reinforced concrete.

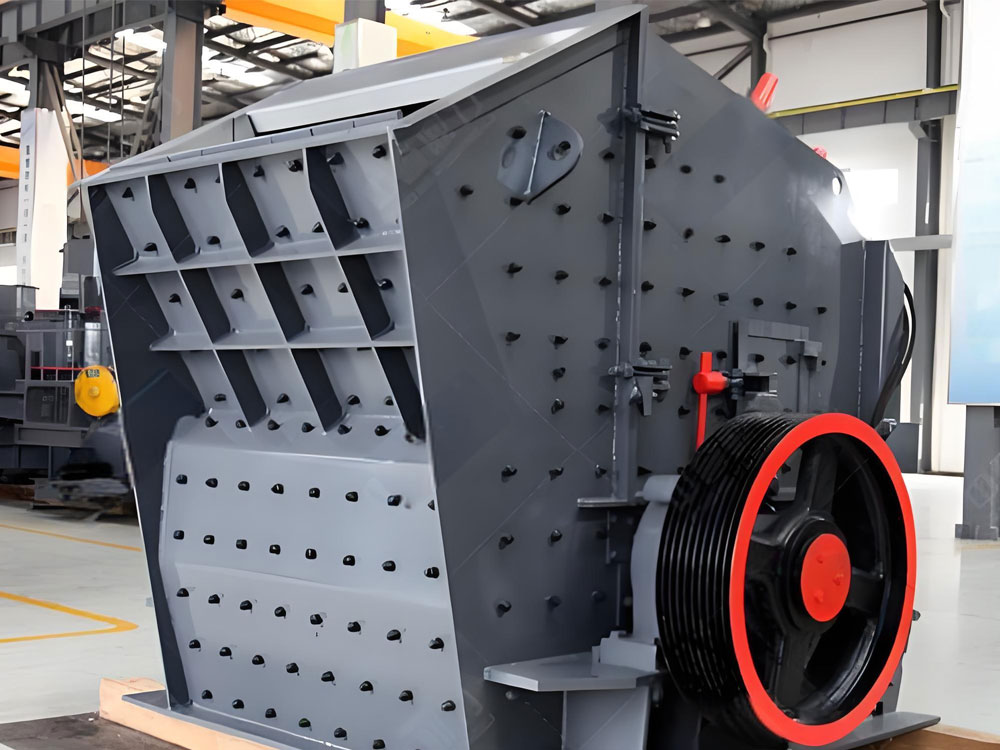

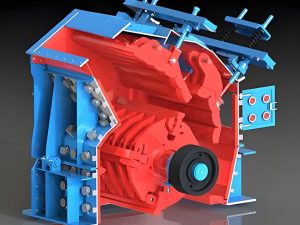

B. Impact Crushers

Perfect for secondary crushing.

Produces uniform, smaller aggregates for reuse.

C. Portable Crushers

Mobile units for on-site crushing.

Eliminates transportation costs of debris.

D. Hydraulic Crushers (Attachments)

Mounted on excavators for precision demolition.

Used in confined spaces.

Pro Tip: For large-scale demolition, a combination of jaw and impact crushers ensures maximum efficiency.

Key Features to Consider When Choosing a Concrete Crusher

Before buying or renting a concrete crusher for demolition, evaluate these factors:

✅ Crushing Capacity – Match the machine’s output (tons per hour) to your project size.

✅ Mobility – Track-mounted crushers offer flexibility on multiple job sites.

✅ Rotor Speed & Power – Higher RPMs improve crushing efficiency.

✅ Dust & Noise Control – Essential for urban demolition projects.

✅ Maintenance Access – Easy-to-replace parts reduce downtime.

Common Mistake: Choosing an undersized crusher leads to frequent breakdowns and delays.

Benefits of Using a Concrete Crusher in Demolition

Why should you invest in a concrete crusher for demolition?

✔ Cost Savings – Recycle debris on-site instead of hauling it away.

✔ Environmental Compliance – Reduces landfill waste and carbon footprint.

✔ Faster Project Completion – Immediate reuse of crushed concrete as base material.

✔ Higher Profit Margins – Sell recycled aggregates for new construction.

Case Study: A demolition company in Texas reduced disposal costs by 60% after switching to on-site crushing.

Top Concrete Crusher Brands & Models for Demolition

Here are some of the most reliable concrete crushers for demolition:

🔹 Komatsu BR380JG-1 (Jaw Crusher) – High mobility and fuel efficiency.

🔹 Sandvik QI341 (Impact Crusher) – Advanced automation for precise crushing.

🔹 RM 120X (Mobile Impact Crusher) – Ideal for small to medium projects.

🔹 Caterpillar CB34B (Hydraulic Crusher) – Perfect for excavator-mounted demolition.

Rental Option: If purchasing isn’t feasible, companies like Sunbelt Rentals offer short-term crusher rentals.

Maintenance Tips for Long-Lasting Performance

To maximize the lifespan of your concrete crusher for demolition, follow these best practices:

🔧 Daily Checks – Inspect belts, hydraulics, and wear parts.

🔧 Lubrication – Keep moving parts well-oiled to prevent overheating.

🔧 Clean After Use – Remove concrete buildup to avoid corrosion.

🔧 Professional Servicing – Schedule annual inspections with certified technicians.

Warning: Neglecting maintenance can lead to 30% higher repair costs over time.