The use of cone crusher

Cone crusher is mainly used in road and bridge construction of fractured rocks, mainly is the main broken bridge and railway production, is unmatched by other crusher. Cone crusher has been production in recent years the adoption of crushing technology and production design of a kind of advanced equipment. Its high power, big crushing ratio, high productivity is unmatched by other type of crusher. Because the machine to implement a new concept, namely hydraulic broken. The birth of the machine marks crusher technology and taking a step forward in our country. The machine and the design structure of the traditional cone crusher and obvious differences on design concept, it is to focus on the advantages of other types of cone crusher.

This machine use range is more extensive; Especially in the ultrafine crushing hard rock, ore, slag, refractory materials, etc. The organizational structure of the machine by the frame body, the adjustment device, adjust the set, broken cone, transmission and eccentric set such as main part and electrical, lubrication, and other auxiliary parts. This machine can be divided into coarse crushing cone crusher, cone crusher and finely cone crusher in three, this series cone crusher, is suitable for crushing medium hardness above all kinds of ores and rocks. The machine broken cavity type is determined by the ore use, standard applied to the ground; Medium in the cone crusher is suitable for the finely. The short head model is suitable for fine grinding. According to the production requirements of the user.

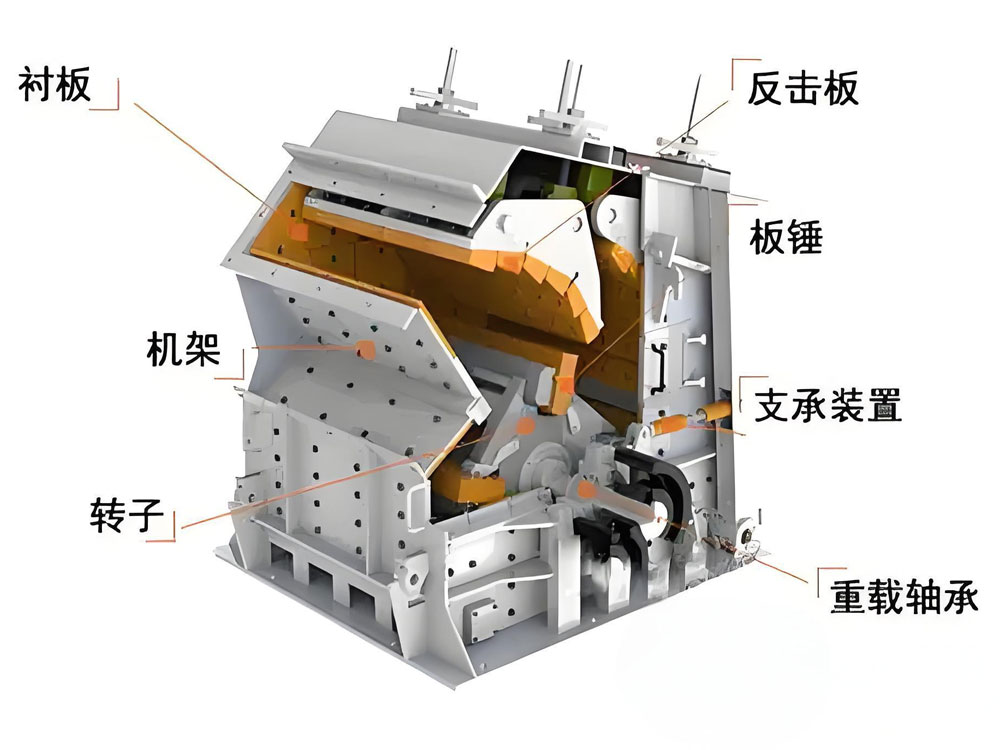

Introduction of cone crusher structure and main parameters: cone crusher the main structure frame, horizontal axis, moving cone, balance wheel, eccentric sleeve, crushing wall (fixed cone), the broken wall (cone), hydraulic coupling, lubrication system, hydraulic system, control system, etc.

Working principle of the cone crusher, cone crusher is working, the rotation of the motor through the pulley or coupling, cone crusher, the shaft and cone crusher cone under eccentric sleeve forced to move around the fixed point for a rotary pendulum movement in a week. So that the broken cone crushing wall and sometimes near and sometimes leave the solid mounted on the adjustment of rolling mortar wall surface, make the ore in the continuing impact crushing cavity, extrusion and bending effect and realization of ore crushing. Motor through the bevel gear drives the eccentric rotation, have made and broken cone rotary pendulum movement. Broken fixed cone, cone and sometimes near and sometimes leave complete crushing and discharging. Support and the frame body joint by spring pressure, falling into a metal piece inside the crusher not broken objects, such as spring compression deformation, namely discharge foreign body, realize the insurance, to prevent the damage of the machine.

Hydraulic cone crusher main features: hydraulic system, the machine hydraulic system is used to adjust the size of the crusher row ore, and the hydraulic system can effectively ensure the safe operation. When a foreign body in the crushing cavity, automatic hydraulic system can make the moving cone back, after the foreign body eduction, the system makes the dynamic cone automatic reset. To keep the original row ore mouth position to continue to work. Crusher cavity type is the main technical indicators broken. The machine from coarse crushing to finely designed four kinds of specifications of the cavity model, it has six possible combinations, which means it can best apply to user's special requirements.

If you are interested in our company's cone crusher, leave a message or E-mail to tell us, we will contact you in time! Website customer service 24 hours online!