Iron Ore Beneficiation Plant

Iron ore processing plant mainly includes hematite and limonite comprehensive beneficiation process, magnetite beneficiation process, hematite and limonite reverse flotation process, hematite and limonite magnetic separation process, in addition to zinc, gold, silver, steel, molybdenum and fluorite ore re-beneficiation process, hematite and limonite re-beneficiation process, etc.

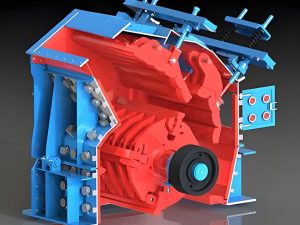

Iron ore beneficiation plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer, mine feeder, hoist and conveyor. It has unique features such as high efficiency, low energy consumption and large capacity

Significance of iron ore beneficiation plant

Ores of different parts have different properties. By dressing experiment, we can fully understand the nature of the ore, and provides guidance on more favorable geological prospecting and help the latter. Beneficiation plant can also provide the basis for plant design and construction. Moreover, the most reasonable structure beneficiation tests can also select the machining factory equipment, looking for investment, costs, indicators, economic optimum balance point, thus reducing the initial investment cost of production and post-production, so the mine to get the maximum economic earnings reduce resource waste mining. We can even say that, in the conditions established under the mineral resources, ore dressing plant is good or bad, but the key to the survival of my interest.

Iron ore beneficiation plant

Mineral processing is based on the physical and chemical properties of ore and ore after crushing ground different minerals, the use of gravity separation, flotation, magnetic separation, electrostatic separation method, etc., would be useful individual minerals and gangue minerals, and each symbiotic (associated) are useful minerals separation as possible, to eliminate or reduce, to obtain smelting or other industrial raw materials required in the process of harmful impurities. Since ferromagnetism relatively large, so the general use of magnetite iron ore beneficiation concentrator.

Magnetite beneficiation

Magnetite beneficiation mainly used different magnetic mineral particles in the sort of non-uniform magnetic field. Ferromagnetic minerals (magnetite and pyrrhotite iron ore, etc.), magnetic separator machine selection is weak; weak magnetic minerals (hematite, siderite, ilmenite ore, tungsten ore, etc.) Strong Magnetic Separators. Weak magnetic separator is mainly open magnetic system, and more from the permanent magnet, the magnetic system strong magnetic separator is closed, the use of electromagnetic magnetic system. Weakly magnetic iron minerals, can also become strong magnetic minerals magnetic roasting and magnetic separator machine selection, then weak.

Free Consultation >>