How to Choose the Right Jaw Crusher for Your Mining or Quarrying Project

How to Choose the Right Jaw Crusher for Your Mining or Quarrying Project

Selecting the right jaw crusher is crucial for optimizing productivity, reducing downtime, and maximizing ROI in mining and quarrying operations. With various types, sizes, and features available, making the best choice requires careful consideration of several factors. This guide will help you evaluate key aspects to ensure you select the most suitable jaw crusher for your project.

Understand Your Crushing Needs

Before choosing a jaw crusher, define your project requirements:

Material Type: Hard rock (granite, basalt), soft rock (limestone), or recycled materials (concrete, asphalt).

Feed Size: Maximum lump size of the raw material.

Output Size: Desired final product size (e.g., 0-50mm for aggregates).

Capacity (TPH): Required tons per hour to meet production demands.

A well-defined crushing plan ensures the selected machine matches your operational needs.

Types of Jaw Crushers

Jaw crushers come in different designs, each suited for specific applications:

Single Toggle Jaw Crusher:

Lighter and more compact.

Better for softer materials and high-capacity crushing.

Double Toggle Jaw Crusher:

More robust, suitable for hard and abrasive materials.

Higher initial cost but longer wear life.

Mobile Jaw Crusher:

Ideal for on-site crushing in quarries or remote locations.

Offers flexibility and reduces material transport costs.

Choosing the right type depends on material hardness, mobility needs, and budget.

Key Features to Consider

When comparing jaw crushers, evaluate these critical features:

Crushing Chamber Design:

Deep or shallow chamber affects capacity and particle shape.

Adjustable Discharge Setting:

Allows control over final product size.

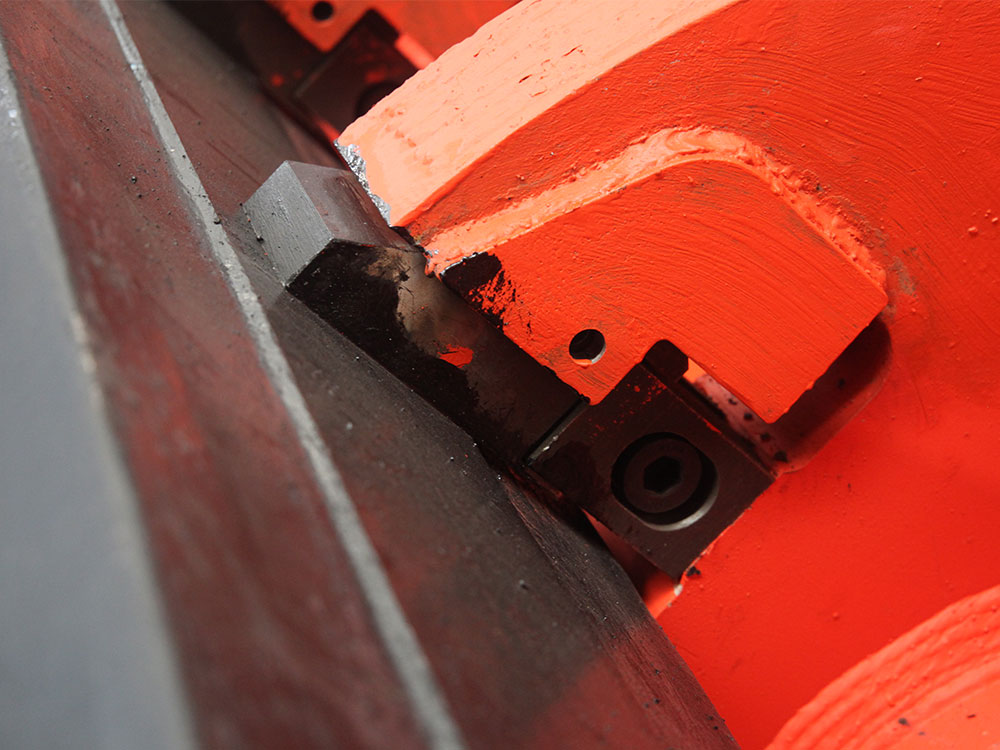

Wear-Resistant Materials:

High-quality manganese steel jaws extend service life.

Hydraulic Adjustment System:

Simplifies setting changes and reduces downtime.

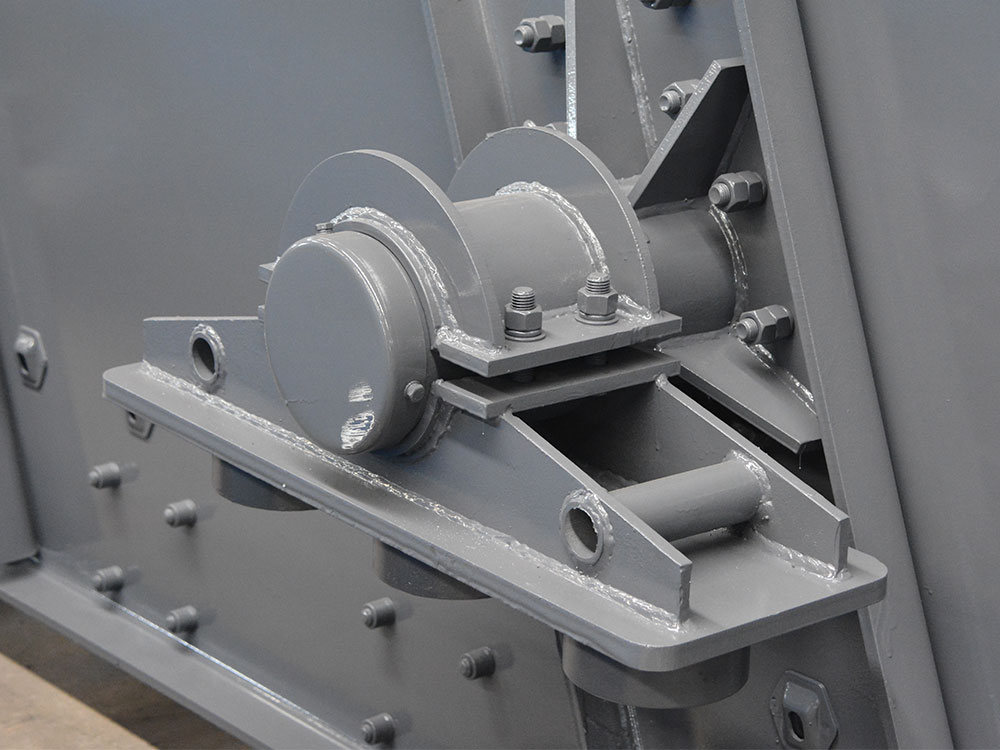

Flywheel Design:

Ensures smooth operation and energy efficiency.

A well-designed crusher improves efficiency and reduces maintenance costs.

Power Source and Energy Efficiency

Jaw crushers can be powered by:

Electric Motors:

Lower operating costs, ideal for fixed installations.

Diesel Engines:

Suitable for remote sites with no grid power.

Hybrid Systems:

Combine electric and diesel for flexibility.

Energy-efficient models reduce operational costs and environmental impact.

Maintenance and Serviceability

A reliable jaw crusher should be easy to maintain:

Accessible Wear Parts:

Quick replacement of jaw plates and liners.

Lubrication System:

Automatic lubrication reduces manual maintenance.

Diagnostic Tools:

Some models offer real-time monitoring for predictive maintenance.

Choosing a user-friendly design minimizes downtime and extends machine life.

Safety and Compliance

Ensure the jaw crusher meets industry safety standards:

Guarding and Emergency Stops:

Prevents accidents during operation.

Dust Suppression Systems:

Reduces airborne particles for worker safety.

Noise Reduction Features:

Compliance with workplace noise regulations.

A safe crusher protects workers and avoids regulatory penalties.

Budget and Long-Term Value

While upfront cost matters, consider long-term expenses:

Initial Investment vs. Operating Costs:

A cheaper machine may have higher maintenance costs.

Resale Value:

Well-built crushers retain value longer.

Warranty & Support:

Reliable after-sales service ensures smooth operation.

Investing in a high-quality jaw crusher improves ROI over time.