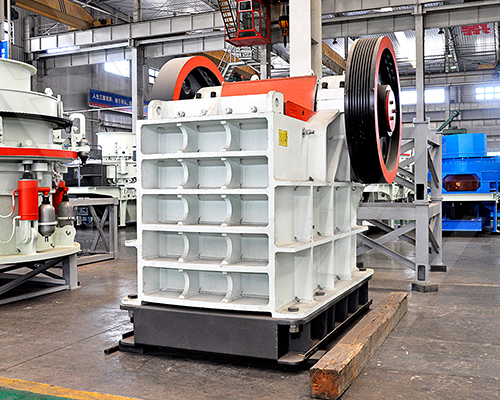

Jaw crusher operation steps

Henan Liming heavy industry science and technology co., LTD. Is a professional manufacturer of crusher, jaw crusher is one of the greatest representative of products and the previous old jaw broken machine bring remarkable good effect, but times in progress, the idea of people also in progress, always stay in place can not meet the new requirements of customers, so we Liming heavy industry is based on the changes of The Times, produced by the requirement is more suitable for use in the new stone production line or a new type of crusher sand production line.

According to before the old design characteristics of the crusher, the new type of crusher adopts hydraulic broken new method, the size and the shape of the stone from the well, particle size uniform, and large capacity, high production efficiency, big crushing ratio, low energy consumption advantages, has been widely used.

Below we detailed introduce to customer jaw crusher from up to shut the correct steps. In strict accordance with the use of the crusher process operation, can avoid the happening of the fault, prolong the service life of equipment.

1. In the jaw crusher, whether need the parts need to check the equipment before starting installed, if there is a deformation occurs. Such as loose, swelled. Focusing on parts jaw plate, bearing, connecting rod, the thrust plate, rod spring, pulley and v belt, etc. You also need to inspection on the jaw crusher peripheral devices.

2. Boot in strict accordance with the boot process when you start, in the process of start the trip if there is an electrical equipment, in the case of don't understand reason cannot blindly try to start in a row, need to find the reason of trip and handle in time. If you have any abnormal situation, run, should suspend operation in a timely manner.

3. The length of time also need to order stop, just stop filling equipment, such as material crusher jaw crusher cavity to eliminate completely, after successive turn off the downstream equipment. After shutdown to check whether there is foreign body crusher cavity. Convenient for restart.