Jaw crusher spare parts replacement method and conditions

Jaw crusher is the most widely used crushing machine, its simple structure, convenient operation, capacity big, sturdy, favored by all walks of life, but the jaw crusher for processing hard material for a long time, so the parts replacement mining machinery frequent some than others. Below we introduced a removal and replacement of the jaw crusher and other considerations.

1. The replacement method of jaw crusher

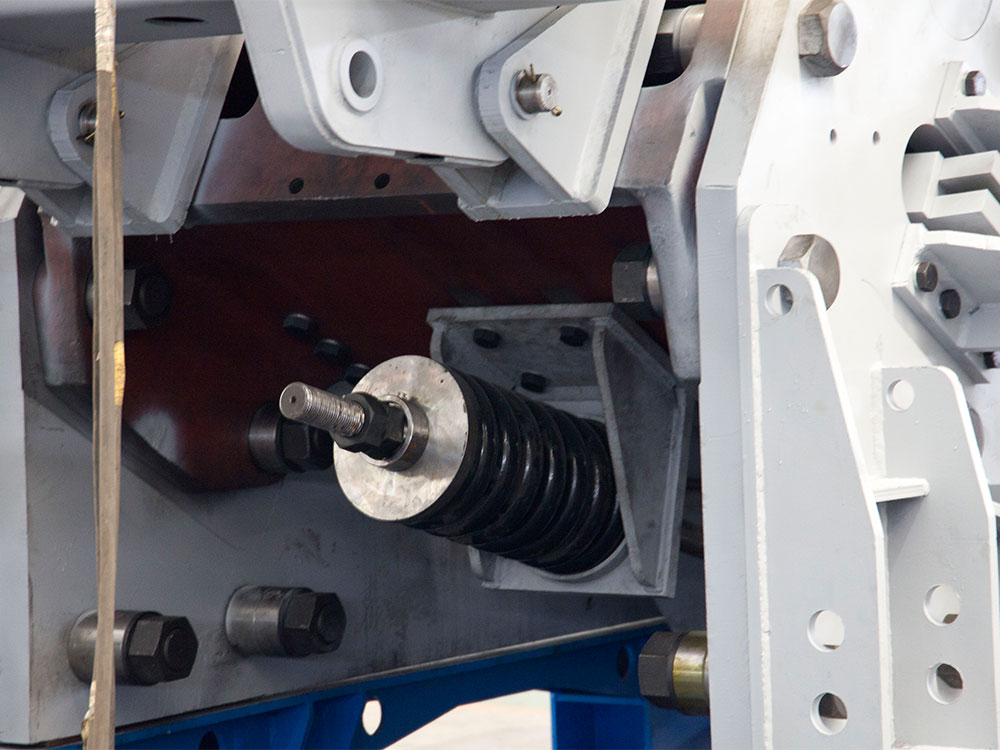

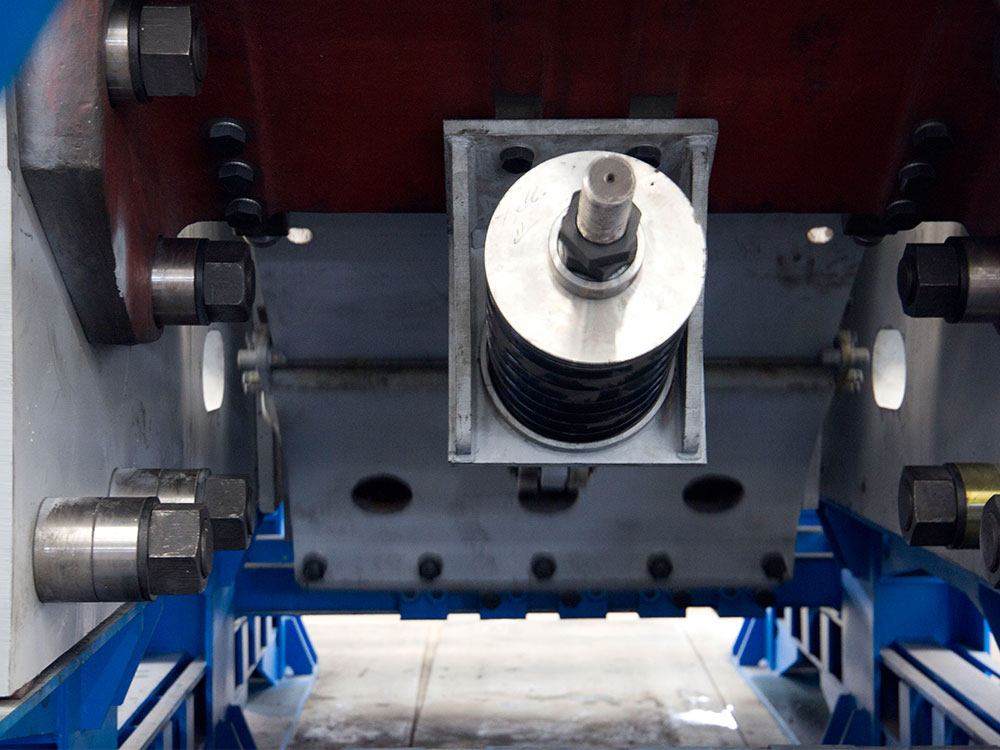

Jaw crusher is the most frequent repair project is to change the thrust plate. Is overall for connecting rod broken confidential remove the thrust plate, must first be wrung out baffle screw laurel, cut off the dry oil lubricating oil tube, the thrust plate hanging on the crane or other lifting equipment lifting hook, then can loosen the horizontal tie rod end of the spring, the moving jaw resistance to the fixed jaw, take out the thrust plate. If you want to take out the thrust plate, connecting rod and the former shall be thrust plate and moving jaw open together, take out after the thrust plate.

Thrust plate after unloading, cut thin oil lubrication and cooling water pipe, lived in the bottom of the connecting rod with support team, and then unloaded connecting rod cover, can the connecting rod.

Hubei broken shaft when removing should be removed with pulley and the flywheel. Removal in the process of the motor (together with the belt) along the slippery course to crusher closer as far as possible, remove the v belt, then crane lift shaft.

For the removal of hubei, must cut off the dry oil lubricating oil pipe, open bar, remove the bearing cover, then moving jaw with a crane or other lifting equipment.

2. The jaw crusher spare parts replacement conditions

2-1.Plate replacement conditions

Fixed jaw plate of jaw crusher (tooth plate), the moving jaw plate (tooth plate), on both sides of the plate (guard) is the most easy to wear. Make the product particle size bigger after serious wear and tear. The early wear and tear, tooth plate can be turned to use, or two pieces of turning up and down. Jaw plate wear and tear, in part, when the depth of tooth wear off 3/5, namely the need to replace a new lining board. On both sides of the liner wear off 2/5, also need to replace new one.

2-2.Hubei broken mandrel, eccentric shaft, bearing replacement conditions

Axis wear if very few, just to repair its geometry, turning on a lathe, make the journal reach the correct geometry, and the decrease of the corresponding bearing inside diameter. But after a few such processing, if the shaft neck size is reduced to 5%, were not allowed to turning again, and should be replaced a new shaft.

Jaw crusher is working under impact load, bearing on babbitt lining, deadlines for about 2 years or so, over time, you need to cast.

If the eccentric shaft and bearing, spindle and bearing is wear, the tip clearance is greater than 1.5 times of the original assembly clearance, need to add cushion adjustment or replacement; Oil groove wear of 1.5 mm, should restart oil groove and adjustment. Connecting rod head cover and the space between the eccentric shaft, wear to greater than 1.5 times of assembly clearance, also need a padded adjust or replace new one.

When the babbitt on the bearing shell has deep peeling or abrasions, shall be cast again. For processing after the quality of the bearing has the following requirements: babbit more uniform, no light, the color of the surface of the silver; Babbitt metal surface layer should not have ash, crack, sand holes, shrinkage cavity and shell, etc.