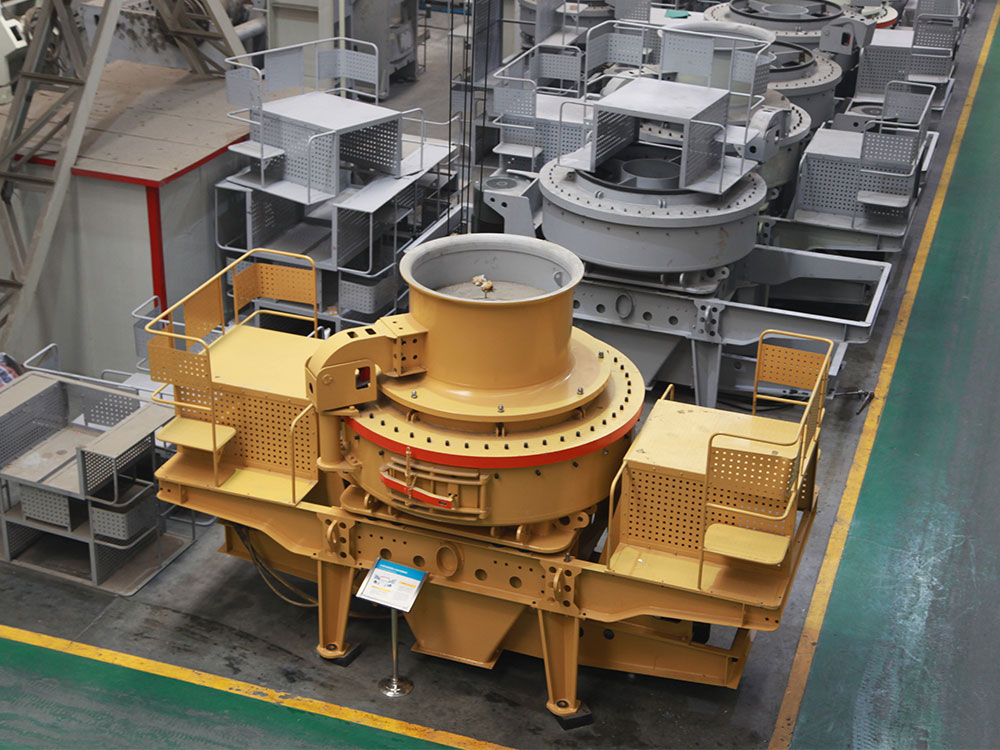

The 1263 impact sand making machine is a cutting-edge equipment designed to produce high-quality artificial sand and aggregates for diverse industrial applications. Known for its robust performance and adaptability, this machine caters to industries such as construction, mining, and infrastructure development. With an impressive hourly output and advanced engineering, the 1263 model stands out as a reliable solution for modern sand production needs.

How the 1263 Impact Sand Making Machine Works

The 1263 impact sand making machine operates on the principle of high-speed centrifugal force. Raw materials, such as stones or gravel, are fed into the machine’s rotor assembly, which accelerates them to a velocity of up to 70 meters per second. These materials then collide with anvils or impact plates within the crushing chamber, resulting in intense fragmentation.

The "stone-on-stone" and "stone-on-iron" crushing mechanisms ensure uniform particle size distribution while minimizing wear on internal components. This process guarantees consistent hourly output of 150–350 tons, depending on material hardness and feed size.

Key Components Enhancing Efficiency

- High-Speed Rotor: Optimized for maximum kinetic energy transfer.

- Hydraulic Adjustable Impact Plates: Enable precise control over final product grading.

- Dust Suppression System: Reduces environmental footprint during operation.

The versatility of the 1263 impact sand making machine makes it a preferred choice across sectors. Below are its primary applications:

1. Construction Industry

From concrete production to plastering sand, this machine delivers finely graded aggregates that meet international standards (e.g., ASTM C33). Its hourly output ensures rapid supply for large-scale projects like skyscrapers and bridges.

2. Mining and Quarrying

The 1263 model efficiently processes ores, limestone, and granite into saleable sand and crushed stone. Its rugged design withstands abrasive materials, reducing downtime in mining operations.

3. Road and Railway Infrastructure

Consistent particle shape and high compaction properties make the machine ideal for producing base layers and asphalt mixtures.

4. Recycling and Waste Management

By repurposing construction waste into reusable sand, the 1263 impact sand making machine supports sustainable practices.

Technical Specifications of the 1263 Impact Sand Making Machine

Understanding the machine’s technical parameters is crucial for optimizing performance. Below are its core specifications:

Model 1263 Impact Sand Making Machine

Max Feed Size 50–60 mm

Capacity (Hourly Output) 150–350 t/h

Rotor Diameter 1,250 mm

Power 250–315 kW

Weight 18–22 tons

Finished Product Size 0–5 mm, adjustable

- Wear-Resistant Liners: Extend service life in abrasive environments.

- Automated Control Systems: Monitor real-time performance and adjust settings remotely.

Advantages of Choosing the 1263 Impact Sand Maker

High Efficiency and Cost Savings

With its remarkable hourly output, the machine reduces operational costs per ton of produced sand. Energy-efficient motors further lower electricity consumption.

Low Maintenance Requirements

Modular design simplifies component replacement, while premium materials like chromium alloys resist wear.

Environmental Compliance

Integrated dust collectors and noise reduction systems align with global environmental regulations.

The 1263 impact sand making machine combines innovation, productivity, and adaptability, making it indispensable for industries requiring high-quality aggregates. Whether for construction, mining, or recycling, its hourly output and technical excellence ensure long-term profitability. Invest in this versatile equipment to stay ahead in competitive markets while meeting sustainability goals.