The CI721 Impact Crusher represents a groundbreaking advancement in the field of hard rock crushing equipment. Designed to address the challenges of processing abrasive materials, this crusher combines innovative engineering with wear-resistant technology to deliver unmatched durability and efficiency. Whether in mining, quarrying, or recycling operations, the CI721 Impact Crusher stands out as a game-changer, offering reduced downtime, lower maintenance costs, and superior performance in demanding environments.

How the CI721 Impact Crusher Works: A Breakdown of Its Mechanism

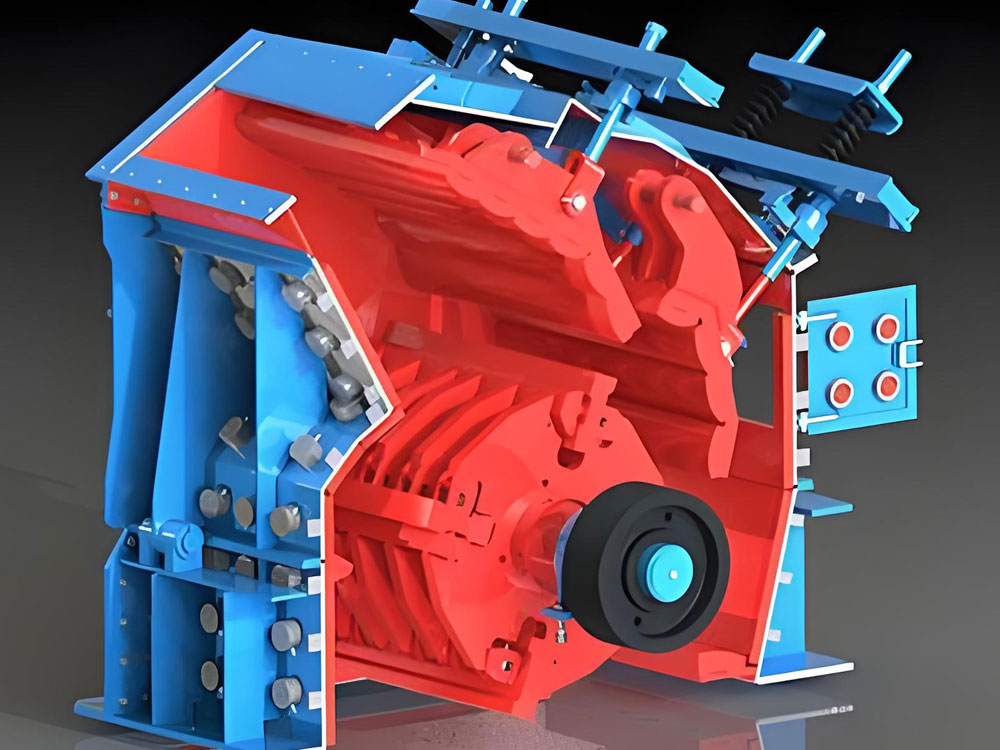

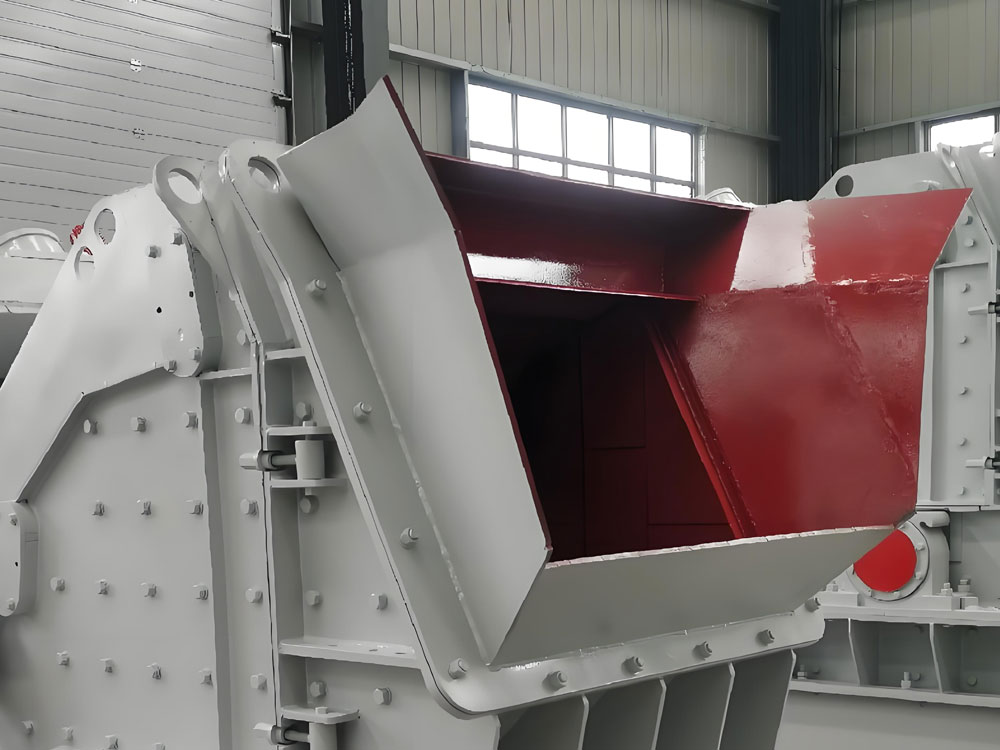

The CI721 Impact Crusher utilizes a high-speed rotor equipped with hammers or blow bars to fracture hard rocks through kinetic energy. As raw material enters the crushing chamber, it is struck by the rotating hammers and thrust against impact plates (liners) lining the interior walls. This repeated collision process reduces the material to the desired size, which then exits through adjustable aprons or grates.

Key Innovations in Wear Resistance

What sets the CI721 crusher model apart is its proprietary wear-resistant design. Critical components such as the rotor, impact plates, and aprons are constructed from advanced alloys and composite materials. These materials are selected for their hardness, toughness, and ability to withstand abrasion caused by granite, basalt, and other hard rocks. Additionally, the CI721 features replaceable wear parts, allowing operators to quickly swap out components without dismantling the entire system—a design that minimizes downtime and extends equipment lifespan.

Applications of the CI721 Impact Crusher: Where It Excels

Mining and Quarrying Operations

The CI721 Impact Crusher is ideally suited for primary and secondary crushing in mining and quarrying applications. Its robust construction enables it to process limestone, granite, and iron ore at high capacities while maintaining consistent output gradation.

Recycling and Aggregate Production

Beyond natural rock processing, the CI721 crusher excels in recycling concrete, asphalt, and demolition waste. Its adjustable settings allow operators to produce precisely sized aggregates for road construction, landscaping, and concrete production.

Industrial and Infrastructure Projects

Large-scale infrastructure projects, such as tunnel excavation and dam construction, benefit from the CI721’s ability to handle oversized rocks and generate uniform particle sizes. Its mobility options (track- or wheel-mounted configurations) further enhance its versatility across job sites.

Technical Specifications: Unpacking the CI721 Impact Crusher’s Capabilities

Power and Performance Metrics

- Rotor Diameter: 1,200 mm

- Rotor Width: 720 mm

- Max Feed Size: 500 mm

- Capacity: 150–300 tons per hour (depending on material and settings)

- Motor Power: 160–250 kW

Advanced Wear-Resistant Components

- Rotor: Fabricated from high-chrome steel with reinforced welding zones.

- Impact Plates: Multi-layer composite liners with replaceable segments.

- Apron Settings: Hydraulically adjustable for precise control over output size.

Dimensions and Mobility

- Weight: 16,500 kg

- Transport Dimensions: 12.5m (L) x 2.8m (W) x 3.2m (H)

- Available Configurations: Track-mounted for on-site mobility or stationary setups.

Advantages of the CI721 Impact Crusher’s Wear-Resistant Technology

Extended Component Lifespan

By integrating ultra-durable materials into its design, the CI721 Impact Crusher reduces wear-related maintenance by up to 40% compared to conventional crushers. This translates to fewer part replacements and longer intervals between service shutdowns.

Energy Efficiency and Cost Savings

The optimized rotor dynamics and low-friction liners minimize energy consumption, lowering operational costs. Combined with reduced downtime, the CI721 delivers a faster return on investment for businesses.

Environmental Sustainability

Efficient crushing reduces waste and energy use, aligning with modern sustainability goals. Additionally, the CI721 crusher’s ability to recycle construction debris supports circular economy initiatives.

Case Studies: Real-World Success with the CI721 Impact Crusher

Quarrying in Scandinavia: Granite Processing

A granite quarry in Norway reported a 30% increase in productivity after switching to the CI721 Impact Crusher. The wear-resistant liners maintained consistent output for over 1,200 hours of operation without requiring replacements.

Urban Recycling Project in Germany

In Berlin, a construction firm utilized the CI721 crusher model to process 50,000 tons of concrete rubble annually. The adjustable aprons enabled precise sizing for reuse in roadbase materials, reducing landfill dependency.

The CI721 Impact Crusher sets a new benchmark for durability, efficiency, and adaptability in the crushing industry. Its wear-resistant design not only addresses the challenges of hard rock processing but also aligns with the growing demand for sustainable, cost-effective solutions.

For mining companies, recyclers, and contractors seeking a reliable crusher that minimizes downtime and maximizes output, the CI721 Impact Crusher is an investment in long-term productivity.