I. Background on Modern Construction Sand and Gravel Demand

With the acceleration of global urbanization, my country's construction industry's annual consumption of sand and gravel aggregates is expected to exceed 20 billion tons by 2025, with the proportion of manufactured sand increasing from 65% in 2020 to 82% in 2025. Taking the Shenzhen Qianhai Free Trade Zone as an example, construction within its square kilometer requires approximately 1.2 million tons of sand and gravel aggregates, placing stringent demands on the efficiency, quality, and environmental friendliness of sand production lines. This solution addresses a production capacity of 600 tons per hour and provides a configuration that balances economic efficiency and sustainability.

II. Core Equipment Configuration and Parameter Optimization

1. Primary Crushing System

Equipment Selection: PE-1200×1500 Jaw Crusher (Processing Capacity 800-1000 t/h)

Technical Parameters: Feed opening dimensions 1200×1500 mm, discharge opening adjustment range 150-300 mm, motor power 220 kW

Application Scenario: Crushing hard materials such as granite (Mohs hardness 6-7) and basalt, with a crushing ratio of up to 6:1

Case Study: Test data from a granite mine in Guangxi showed that after 72 hours of continuous operation, the bearing temperature remained stable below 65°C, with a failure rate of less than 0.3%.

2. Medium Crushing System

High-hardness Material Solution:

Main Equipment: SC315S Single-Cylinder Hydraulic Cone Crusher (450-650 t/h Capacity)

Auxiliary Equipment: Two HXHP500 Multi-Cylinder Cone Crusher (300-450 t/h Capacity per Unit)

Technical Highlight: The laminated crushing principle reduces the flake content to ≤8%, far exceeding the national standard requirement of 15%.

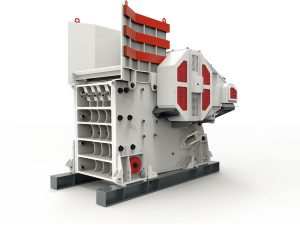

Medium-to-Low Hardness Material Solution:

PF-1820 Impact Crusher (300-500 t/h Capacity)

Advantage: The finished product has a cubic content of ≥90%, making it suitable for concrete aggregates.

Energy Consumption Comparison: The cone crusher consumes 1.2 kWh/t of electricity per ton, while the impact crusher consumes 1.5 kWh/t. However, the impact crusher has 35% lower maintenance costs.

3. Sand Making and Shaping System

Equipment Selection: HVI1250 Vertical Shaft Impact Sand Making Machine (200-350 t/h capacity)

Technical Breakthroughs:

Deep-cavity rotor design increases throughput by 20%

Frequency-controlled fineness modulus (2.2-3.0) meets the requirements of C30-C60 concrete grades

Stone dust content can be controlled within a range of 3-8%

Shaping Effect: After treatment with this equipment, aggregate crushing value is reduced from 18% to 12%, and Los Angeles abrasion resistance value is reduced from 28% to 22%.

4. Screening and Environmental Protection System

Screening Equipment: 3YK3072 three-stage vibrating screen (processing capacity 600 t/h)

Screen Mesh Specifications: 5mm, 10mm, and 20mm three-layer composite screen

Screening Efficiency: ≥95%, False Elimination Rate ≤2%

Environmental Protection Devices:

Pulse Dust Collector: Filtration Area 1200 m², Emission Concentration ≤10 mg/m³

Mist Cannon Dust Suppression: Coverage Radius 50 m, Dust Suppression Efficiency 85%

Noise Reduction Design: Overall Equipment Operating Noise ≤75 dB(A)

III. Project Case Studies

1. Granite Project (Quanzhou, Fujian)

Configuration: PE-1500×1800 jaw crusher + SC315S cone crusher + PF-1520 impact crusher

Results:

Production capacity: 620 tons per hour, with 35% of the finished product containing 0-5mm manufactured sand.

Power consumption: 18 kWh/t, a 12% reduction compared to traditional processes.

Dust emission concentration: 8.2 mg/m³, exceeding EU standards.

2. Limestone Project (Luoyang, Henan)

Configuration: PE-900×1200 jaw crusher + PF-1315 impact crusher + HVI800 sand maker

Investment Analysis:

Total equipment investment: 6.8 million yuan, including installation and commissioning.

Annual operating costs: 2.4 million yuan (including electricity, wearing parts, and labor).

Payback period: 1.8 years (based on a manufactured sand price of 85 yuan/ton).

IV. System Optimization Suggestions

1. Capacity Matching Optimization

The secondary crushing equipment's processing capacity should be ≥ 120% of the primary crushing equipment's (e.g., if primary crushing is 800 t/h, secondary crushing requires ≥ 960 t/h).

Buffer Bin Capacity Design: Configured at 1.5 times the maximum processing capacity (900 m³ is required for this solution).

2. Fine Sand Recovery System

Configuration: XS3020 fine sand recovery machine (processing capacity 150-200 t/h)

Benefit Analysis:

Sand output rate increased by 8-10% (from 65% to 73%)

Water recycling rate reached 90%, saving 30%

Fine sand recovery cost is only 12 yuan/ton, lower than the external purchase price (45 yuan/ton)

3. Intelligent Control System

Deployment: PLC + SCADA system, achieving:

Real-time monitoring of 12 parameters including equipment vibration, temperature, and current

Automatic adjustment of feed rate to maintain the optimal load factor between 85% and 90%

Fault warning accuracy ≥ 95%, reducing unplanned downtime