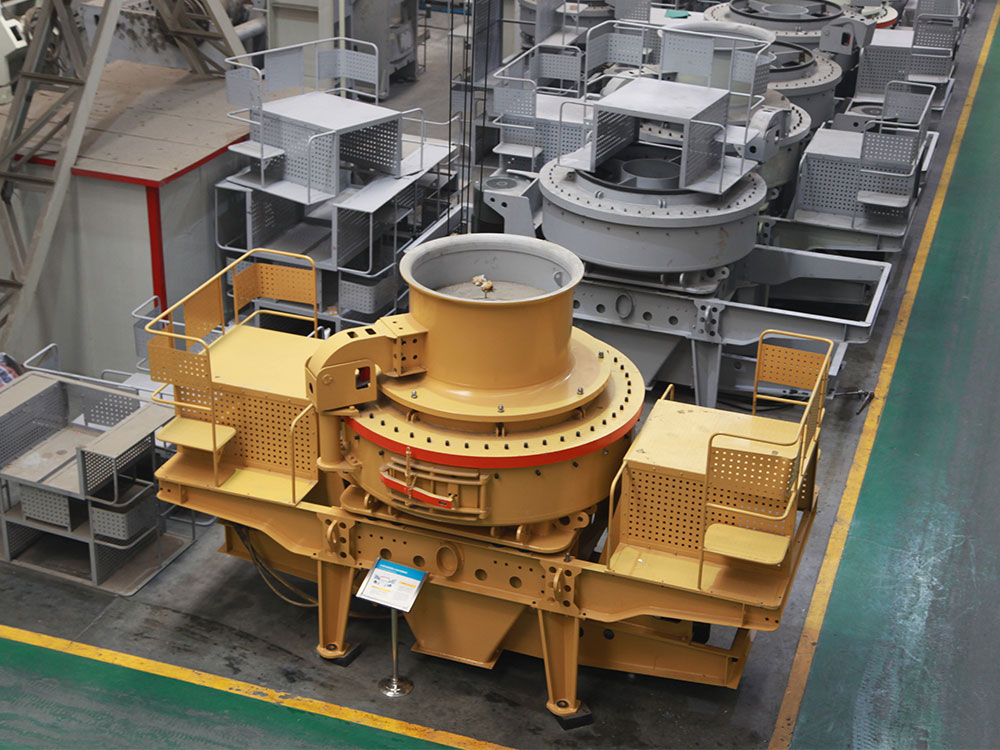

Vertical Shaft Impact Crusher, as a high-efficiency stone crushing and sand making equipment, has shown its unique advantages and wide application value in many industries. Its main features cover the following aspects:

Diversified Working Principle

Vertical Shaft Impact Crusher combines two crushing modes: stone hitting stone and stone hitting iron, providing more choices for users. Stoning mode realizes material shaping through multiple cyclic impacts between materials, and the grain shape obtained in this mode is better, which is very suitable for occasions with high requirements on grain shape. However, it should be noted that due to multiple impacts, the powder content may be relatively high. The stone hitting iron mode is the direct impact between the material and the counterattack block, which can provide a larger crushing ratio and is suitable for occasions with high requirements on crushing efficiency.

Excellent Sand Making Effectiveness

The sand and gravel aggregate crushed by the vertical shaft impact crusher mostly shows a cubic shape, with a low content of needles and flakes, and without internal cracks. This high-quality sand and gravel aggregate has a wide range of applications in concrete, asphalt and other building materials. Its sand formation rate can be as high as about 90%, which can meet the demand for large quantity of sand production. At the same time, the fineness modulus can be adjusted according to actual needs, making the product more in line with the specific requirements of users.

Structure with excellent durability

In order to ensure the stability and durability of the equipment, the Vertical Shaft Impact Breaker adopts a special willow welding process to enhance the strength of the machine body. This process not only improves the overall rigidity of the equipment, but also effectively reduces the occurrence of resonance failures and extends the service life of the equipment. In addition, the equipment is also equipped with perfect safety protection mechanisms, such as overload protection, power failure protection, etc., to ensure the stability and safety of the production process.

Wide material applicability

Vertical Shaft Impact Crusher is especially suitable for medium hardness materials, such as basalt, cobblestone and lapis lazuli slabs. These materials produce less dust in the crushing process and have a higher sand formation rate. At the same time, the equipment also has good adaptability to wet and sticky materials, and can maintain high crushing efficiency and sand quality. This makes the Vertical Shaft Impact Crusher play an excellent performance in a variety of material processing occasions.

Long service life of wear parts

The wear parts of the equipment are the key components in the crushing process, and their quality directly affects the crushing efficiency and service life of the equipment. The wear-resistant parts of the Vertical Shaft Impactor are made of high quality materials and advanced manufacturing technology, which have extremely high wear resistance and impact resistance. When crushing hard materials, these wear parts can be used for more than one year; when crushing soft materials, their service life can even be as long as three years. This not only reduces the user's maintenance costs, but also improves the overall cost-effectiveness of the equipment.

Application Cases and Data Support

Taking a mining enterprise as an example, the production efficiency of this enterprise has been significantly improved after the introduction of the Vertical Shaft Impact Crusher. According to statistics, compared with traditional crushing equipment, the crushing efficiency of the vertical shaft impact breaker has increased by about 30%, and the sand making efficiency has increased by about 25%. At the same time, the energy consumption of this equipment is also relatively low, saving a lot of energy costs for the enterprise. In addition, due to the high quality and even grain size of the finished products, the enterprise's products have also gained a better reputation and higher selling price in the market.

With its diversified working principle, excellent sand making effectiveness, outstanding durability, wide material applicability and long service life of wearing parts, the Vertical Shaft Impact Crusher has become an ideal choice in the minds of many users. In the future development, with the continuous progress of technology and market expansion, the Vertical Shaft Impact Crusher is expected to show its unique advantages and value in more fields.