Hard rock crushing production lines, as a critical component of modern mining and building materials production, rely on a series of precisely designed core steps for efficient operation. These steps integrate intelligent control and fine screening technology to ensure the high-quality achievement of large-scale production goals. The following is a detailed analysis of these core steps:

1. Preliminary Crushing Stage: Laying the Foundation

In this stage, raw materials are first fed into a vibrating feeder, which uses precise vibration frequency and amplitude to ensure that materials are uniformly and continuously fed into the jaw crusher. The jaw crusher, as the first stage of hard rock crushing, boasts remarkable crushing capacity. It can easily handle hard rocks such as granite and basalt with a compressive strength of up to 320 MPa, with a maximum feed size of an impressive 1,200 mm and an hourly output of up to 1,600 tons. This high-efficiency processing capability lays a solid foundation for subsequent processes. The preliminarily crushed material is then transported smoothly and quickly to the next process via a robust and durable belt conveyor, ensuring the smooth operation of the entire production line.

II. Intermediate and Fine Crushing Stages: Pursuing Excellence

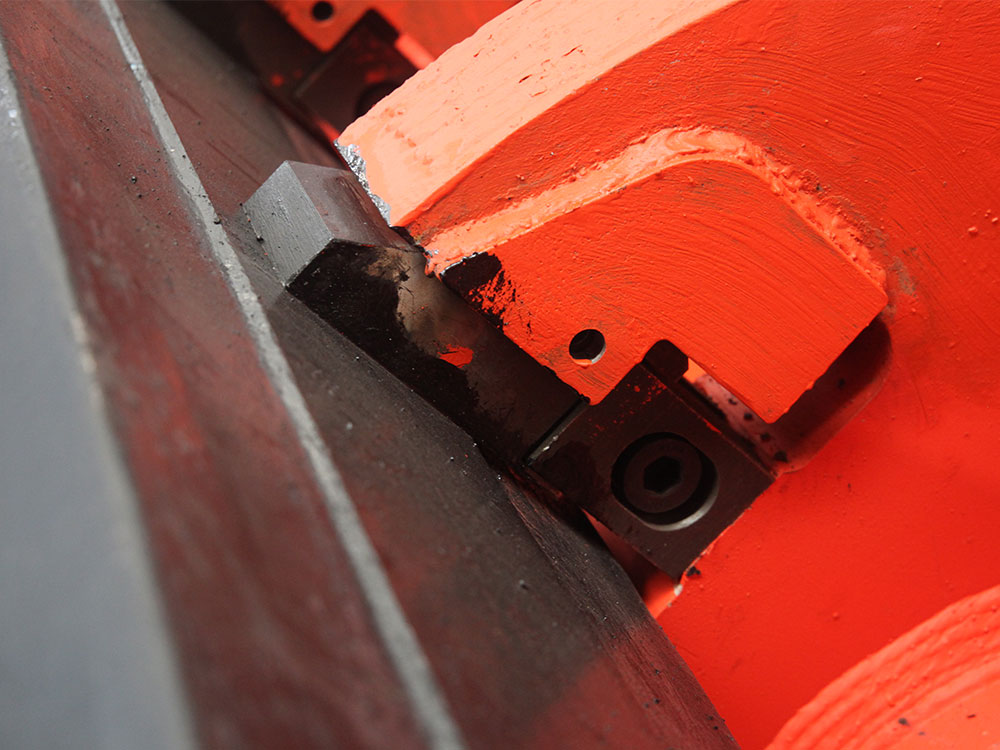

In the secondary crushing stage, the coarse-crushed material is fed into a cone crusher (single-cylinder or multi-cylinder hydraulic type). This equipment, renowned for its exceptional crushing performance and wear resistance, is an ideal choice for processing materials with a particle size of up to 450mm. With a maximum hourly output of 2,000 tons, it fully meets the demands of large-scale production. Given the hardness of hard rock, the wear resistance of the cone crusher is particularly critical. Therefore, when selecting the equipment, special attention should be paid to its wear-resistant materials and structural design to avoid using easily damaged impact crushers, thereby ensuring the stability and durability of the production line.

The tertiary crushing stage is determined based on specific requirements. After screening, if there are still materials with a particle size greater than 315mm, these materials will be returned to the multi-cylinder hydraulic cone crusher for re-crushing, forming a closed-loop process. This step's precise control ensures the uniformity of particle size and stability of quality in the final product.

3. Sand-making and shaping stage: Shaping perfection

In the sand-making and shaping stage, crushed stone meeting sand-making requirements (typically no larger than 20mm) is fed into advanced impact sand-making machines (e.g., VSI5X, VSI6X series). These sand-making machines use a “stone-on-stone” or “stone-on-iron” working method to efficiently shape the materials. Through a carefully designed impact and grinding process, the produced manufactured sand has excellent particle shape and reasonable gradation, meeting the requirements of high-standard building materials.

4. Screening and Grading Stage: Precise Separation

The screening and grading stage is an indispensable part of the entire production line. During the pre-screening process, the output from the cone crusher is finely separated by a heavy-duty vibrating screen, with materials larger than 315mm accurately identified and returned to the tertiary crushing process for reprocessing. The finished product screening stage is even more meticulous, with multi-layer vibrating screens dividing the sand-making material into different specifications such as 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm. This precise separation ensures the diversity and applicability of the final product. Particles that do not meet the standards are returned to the sand-making machine or cone crusher for further processing until they meet the requirements.

5. Intelligent Control and Storage Process: Smart Leadership

In terms of full-process automation, the central control system plays a crucial role. By intelligently regulating feed rate, equipment start/stop, and fault diagnosis, it achieves automated operation and intelligent management of the entire production line. The application of this system not only improves production efficiency and quality stability but also significantly reduces labor costs and failure rates.

The enclosed storage process ensures the safety and traceability of finished aggregates. Finished aggregates are conveyed via a belt conveyor into fully enclosed silos, effectively preventing contamination and interference from external environments. Additionally, the silos support automatic loading operations, further enhancing the automation level and operational efficiency of the production line.