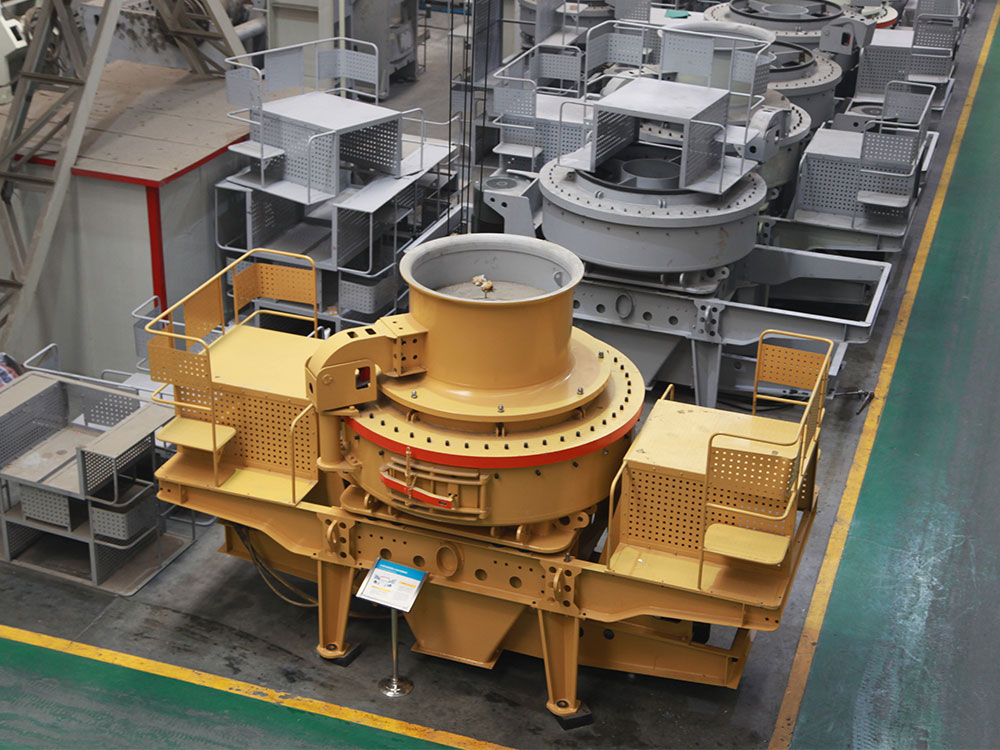

The VSI sand making machine, as an outstanding representative of the modern sand making industry, is leading the new trend of green and efficient production of high-quality artificial sand with its cutting-edge technical architecture and outstanding environmental performance. It has already set an unshakable benchmark in this field and has become an indispensable core equipment for many engineering projects. Its main highlights are specifically reflected in the following aspects:

Outstanding Environmental Performance:

In today's world where environmental protection has become a focal point of industry concern, the VSI sand-making machine demonstrates exceptional environmental capabilities. Its dust control technology is unparalleled, utilizing a uniquely designed airflow recirculation mechanism to significantly reduce exhaust air volume. Traditionally, conventional sand-making equipment often generates large amounts of dust during operation, severely polluting the work environment and posing a threat to the health of workers. The innovative design of the VSI sand-making machine effectively prevents dust leakage, significantly reducing dust concentration at the worksite and creating a cleaner, healthier working environment for staff. For example, after a large sand-making plant adopted the VSI sand-making machine, dust concentration in the work area decreased from hundreds of milligrams per cubic meter to just tens of milligrams per cubic meter, greatly improving the working environment.

Additionally, the sand-making machine also excels in energy conservation and consumption reduction. By optimizing the design of the load-bearing wheels, the energy consumption during operation has been reduced. The load-bearing wheel design of traditional sand-making equipment is often unreasonable, leading to high energy consumption during operation. After in-depth research and practical testing, the VSI sand-making machine has optimized and improved the load-bearing wheels, making the equipment more stable during operation and significantly reducing energy consumption. Furthermore, the use of a稀油 lubrication system reduces friction-related wear between components, enabling efficient and low-energy operation. The稀油 lubrication system ensures adequate lubrication between all components, minimizing energy loss caused by friction and saving the company substantial operational costs. According to calculations, the energy consumption costs for the company have decreased by approximately 20% after adopting the VSI sand-making machine.

What is even more noteworthy is that the VSI sand-making machine also has the ability to recycle and reuse resources, capable of processing construction waste, slag, and other industrial waste. With the acceleration of urbanization, the production of construction waste and slag has been increasing, and these wastes not only occupy a large amount of land resources but also cause severe environmental pollution. The VSI sand-making machine can crush and process these wastes into reusable sand and gravel aggregates, thereby alleviating environmental pollution pressure and improving resource reuse rates, achieving a win-win situation for both economic and environmental benefits. For example, a certain city processed construction waste using the VSI sand-making machine and used it for urban road construction, thereby solving the problem of construction waste disposal while providing high-quality sand and gravel aggregates for road construction and reducing construction costs.

Balancing production efficiency and product quality:

In terms of production efficiency and product quality, the VSI sand-making machine also performs exceptionally well. Its deep-cavity rotor technology significantly enhances feeding capacity, with the deep-cavity rotor design enabling a larger feed opening to accommodate more material while increasing material throughput speed. Combining the “stone-on-stone” and “stone-on-iron” crushing modes, the machine achieves a maximum hourly output of 640 tons, meeting the demands of large-scale production. In the “stone-on-stone” mode, materials collide and break against each other within the rotor, suitable for crushing high-hardness materials; in the “stone-on-iron” mode, materials collide and break against components like the impact plate, suitable for crushing low-hardness materials. The combination of these two crushing modes enables the VSI sand-making machine to adapt to different material crushing requirements, thereby improving production efficiency.

Additionally, the manufactured sand produced by this machine has a cubic shape, reasonable gradation, and a flexible adjustment of the fineness modulus, with quality far exceeding that of natural sand. Natural sand, however, is limited by natural conditions, resulting in less-than-ideal particle size distribution and fineness modulus, often failing to meet the requirements of high-standard engineering projects. In contrast, the VSI sand-making machine can adjust equipment parameters to flexibly control the fineness modulus, ensuring more reasonable particle size distribution and more stable quality of the manufactured sand. This provides high-quality aggregate materials for engineering projects, ensuring project quality and safety.

In addition, the VSI sand making machine also has the three functions of crushing, sand making, and shaping, which significantly improves the surface energy and water clarity of sand and gravel aggregates. The surface energy and water clarity of sand and gravel aggregates have an important impact on the performance of concrete. The higher the surface energy, the stronger the bonding force between sand and gravel aggregates and cement and other cementitious materials; the better the water clarity, the more uniform the dispersion of sand and gravel aggregates in concrete. Through its unique crushing and sand-making process, the VSI sand-making machine significantly improves the surface energy and water-repellency of sand and gravel aggregates, enhancing their application performance in concrete and increasing the strength and durability of the concrete.

Intelligent Maintenance and Durability:

In terms of intelligent maintenance and durability, the VSI sand-making machine also demonstrates its unique advantages. Its wear-resistant modular design, such as the combination hammerhead and adjustable head guard plate structures, reduces the replacement cost of wear parts by over 30%. Traditional sand-making equipment often has high replacement costs for wear parts, and the replacement process is cumbersome, requiring prolonged downtime. The VSI sand-making machine's wear-resistant modular design allows for easy disassembly and replacement of wear parts, reducing replacement costs and time. For example, the design of the combination hammer head allows for the replacement of a single hammer head when it is severely worn, rather than replacing the entire hammer head assembly, significantly reducing costs.

Additionally, the multi-directional inspection door design facilitates daily maintenance, and the impact plate adjustment mechanism allows for on-the-fly adjustment of output particle size without shutting down the machine. The multi-directional inspection door enables staff to observe and inspect the interior of the equipment, promptly identifying and addressing potential issues. The impact plate adjustment mechanism allows for on-the-fly adjustment of output particle size without shutting down the machine, making the production process more flexible and enabling timely adjustments to output particle size based on actual needs, significantly improving production efficiency.

Furthermore, the VSI sand-making machine employs a high-manganese steel frame and ultra-wear-resistant materials, combined with a reasonable collision angle design, significantly reducing wear on vulnerable components and extending the equipment's service life. The high-manganese steel frame offers high strength and toughness, capable of withstanding the immense impact forces generated during operation; the use of ultra-wear-resistant materials enhances the durability of critical components, minimizing failures caused by wear. The reasonable collision angle design ensures that materials are subjected to more uniform force during the crushing process, reducing localized wear on wear-prone components and further extending the equipment's service life. According to statistics, the average service life of the equipment has been extended by approximately 30% compared to previous models after using the VSI sand-making machine.

Wide range of applications:

The VSI sand-making machine has a wide range of applications and is suitable for high-standard engineering projects such as highways, high-rise buildings, and hydroelectric dams. In highway construction, high-quality aggregate is crucial for ensuring road surface smoothness and strength. The manufactured sand produced by the VSI sand-making machine meets the stringent requirements for aggregate in highway construction, providing a strong guarantee for the smooth progress of highway projects. In high-rise buildings, the quality of aggregate directly impacts structural safety and stability. The manufactured sand produced by the VSI sand-making machine features reasonable gradation and stable quality, meeting the stringent requirements for sand and gravel aggregates in high-rise buildings. In hydroelectric dam construction, sand and gravel aggregates must withstand immense water pressure and impact forces. The manufactured sand produced by the VSI sand-making machine meets the high strength and durability requirements for sand and gravel aggregates in hydroelectric dam construction.

It can process various raw materials such as ore and solid waste, meeting diverse production needs. Whether for large-scale infrastructure projects or small-scale engineering projects, the VSI sand-making machine delivers superior performance and consistent quality, providing high-quality sand and gravel aggregates to ensure the smooth progress of engineering projects. For example, in a small-scale mining project, the VSI sand-making machine processed ore through crushing and sand-making, supplying the required sand and gravel aggregates for the mining project, thereby reducing production costs and enhancing economic efficiency.

With its cutting-edge technical architecture, outstanding environmental performance, high production efficiency, superior product quality, intelligent maintenance methods, and durable characteristics, the VSI sand-making machine has become a benchmark device for green, efficient production of high-quality manufactured sand. It has injected new vitality into the development of the modern sand-making industry, driving the industry toward a more green, efficient, and intelligent direction.