Introduction to Heavy Rotor Design in Impact Crushers

Impact crushers are pivotal equipment in industries requiring material size reduction, from mining to recycling. At the heart of their performance lies the heavy rotor design, a technological innovation that enhances crushing efficiency, durability, and operational reliability. This article delves into the working principles, applications, and technical specifications of impact crushers equipped with heavy-duty rotor systems, emphasizing how this design elevates their functionality.

How Does the Heavy Rotor Design Work in Impact Crushers?

The heavy rotor design in impact crushers revolves around a robust, high-inertia rotor assembly. This rotor is typically composed of a large-diameter steel disk or drum fitted with wear-resistant hammers or blow bars. When the crusher operates, the rotor spins at high velocities, generating centrifugal force that propels incoming materials against stationary impact plates or aprons.

The weight and structural integrity of the heavy rotor ensure two critical outcomes:

1. Enhanced Kinetic Energy Transfer: The rotor’s mass allows it to store and release substantial kinetic energy, enabling efficient fragmentation of hard or bulky materials.

2. Reduced Vibration and Wear: A heavier rotor minimizes unbalanced forces, lowering mechanical stress on bearings and extending component lifespan.

Key Components Supporting the Heavy Rotor

- High-Strength Materials: Rotors are forged from alloy steels or composite metals to withstand repetitive impacts.

- Adjustable Blow Bars: These components can be repositioned or replaced to optimize crushing angles and adapt to varying material types.

- Dual Drive Systems: Some models employ dual motors to ensure consistent rotor speed under heavy loads.

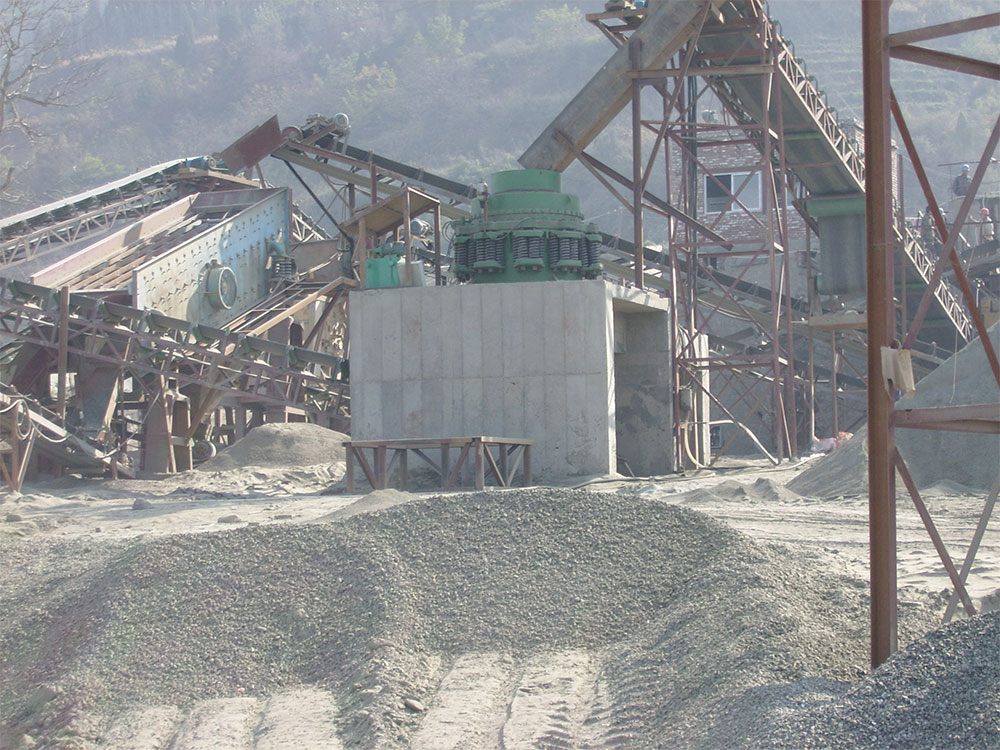

Applications of Impact Crushers with Heavy Rotor Design

Mining and Quarrying

In mining operations, impact crushers with heavy rotors excel at processing abrasive ores, limestone, and granite. Their ability to handle high-tonnage workloads makes them ideal for primary and secondary crushing stages.

Construction and Demolition Waste Recycling

The heavy-duty rotor design enables efficient recycling of concrete, asphalt, and bricks. By reducing particle size uniformly, these crushers support sustainable material reuse in new construction projects.

Industrial Mineral Processing

From coal to gypsum, industries leverage the high inertia of heavy rotors to achieve precise size distribution, critical for downstream processes like milling or pelletizing.

Aggregate Production

Producing high-quality sand and gravel for road construction or concrete requires consistent output—a strength of heavy rotor-equipped impact crushers.

Technical Specifications of Heavy Rotor Impact Crushers

Rotor Dimensions and Weight

- Diameter: Ranges from 1,000 mm to 2,500 mm, depending on crusher size.

- Weight: Typically between 5,000 kg and 30,000 kg, ensuring optimal inertia.

- Speed: Operates at 500–1,200 RPM, balancing energy consumption and crushing force.

Material Throughput Capacity

- Maximum Feed Size: Up to 1,500 mm for large-scale models.

- Output Size: Adjustable between 20 mm and 150 mm via hydraulic or mechanical settings.

- Hourly Production: Varies from 200 tons/hour (mid-sized units) to 2,500 tons/hour (industrial crushers).

Power Requirements

- Motor Power: 200 kW to 1,500 kW, depending on rotor mass and application.

- Energy Efficiency: Advanced designs reduce kWh per ton by 15–20% compared to conventional rotors.

Advantages of Heavy Rotor Design in Impact Crushers

Superior Crushing Efficiency

The heavy rotor design maximizes energy transfer to materials, reducing the need for multiple crushing stages. This efficiency translates to lower operational costs and faster project completion.

Extended Equipment Lifespan

Heavy rotors distribute stress evenly, minimizing wear on blow bars, bearings, and impact plates. Premium models feature replaceable rotor discs, further cutting long-term maintenance expenses.

Versatility Across Material Types

Whether crushing soft limestone or ultra-hard quartzite, the adjustable rotor speed and blow bar configurations ensure consistent performance.

Reduced Downtime

Modular designs allow quick component replacement, while advanced monitoring systems predict failures before they occur.

Maintenance Tips for Heavy Rotor Impact Crushers

Regular Inspection Routines

- Check blow bar thickness and alignment every 100 operating hours.

- Monitor rotor balance using vibration sensors to prevent uneven wear.

Lubrication Best Practices

- Use high-temperature grease for rotor bearings to withstand heavy loads.

- Follow manufacturer-recommended intervals for oil changes in hydraulic systems.

Wear Part Replacement

- Rotate or replace blow bars once wear exceeds 30% of original thickness.

- Inspect rotor discs for cracks during annual shutdowns.

Future Trends in Heavy Rotor Technology

Smart Rotor Systems

Integration of IoT sensors enables real-time tracking of rotor temperature, vibration, and wear rates. This data-driven approach optimizes maintenance schedules and boosts uptime.

Eco-Friendly Materials

Manufacturers are experimenting with recycled alloys and ceramic composites to reduce the carbon footprint of rotor production.

Hybrid Drive Systems

Combining electric motors with energy recovery mechanisms (e.g., regenerative braking) further enhances the sustainability of heavy rotor impact crushers.

The heavy rotor design in impact crushers represents a breakthrough in material processing technology. By combining unmatched durability, energy efficiency, and adaptability, these systems are transforming industries from mining to recycling. As manufacturers continue to innovate—integrating smart technologies and sustainable materials—the future of heavy-duty rotor systems looks poised to set new benchmarks in crushing performance.

For operations demanding reliability and cost-effectiveness, investing in an impact crusher with a heavy rotor isn’t just a choice—it’s a strategic advantage.