In response to the specific requirements of the mobile stone production line for feed particle size of 80 cm (i.e., 800 mm) and output particle size of 0-30 mm, we have carefully developed the following comprehensive solution based on highly reliable information, aiming to ensure the efficient, stable, and environmentally friendly operation of the production line.

I. Selection of Core Equipment

Coarse Crushing Stage

In the coarse crushing stage, we recommend using a mobile jaw crusher as the first crushing process. This equipment is renowned for its powerful crushing capacity and flexible mobility, with a feed opening width sufficient to accommodate large raw material pieces of 800 millimeters. We particularly recommend the CJ120 model (with a feed opening size of 1060×700 millimeters, capable of processing particles up to 560 millimeters in size; however, considering actual feed requirements, this equipment can easily handle raw materials up to 800 millimeters in size by adjusting the crushing chamber and feed method) or similar specifications. These machines not only offer high-efficiency crushing capabilities but also feature hydraulic adjustment of the discharge opening, allowing flexible adjustment of the discharge particle size according to the requirements of subsequent crushing processes, thereby laying a solid foundation for the subsequent medium and fine crushing stages.

Medium and Fine Crushing Stage

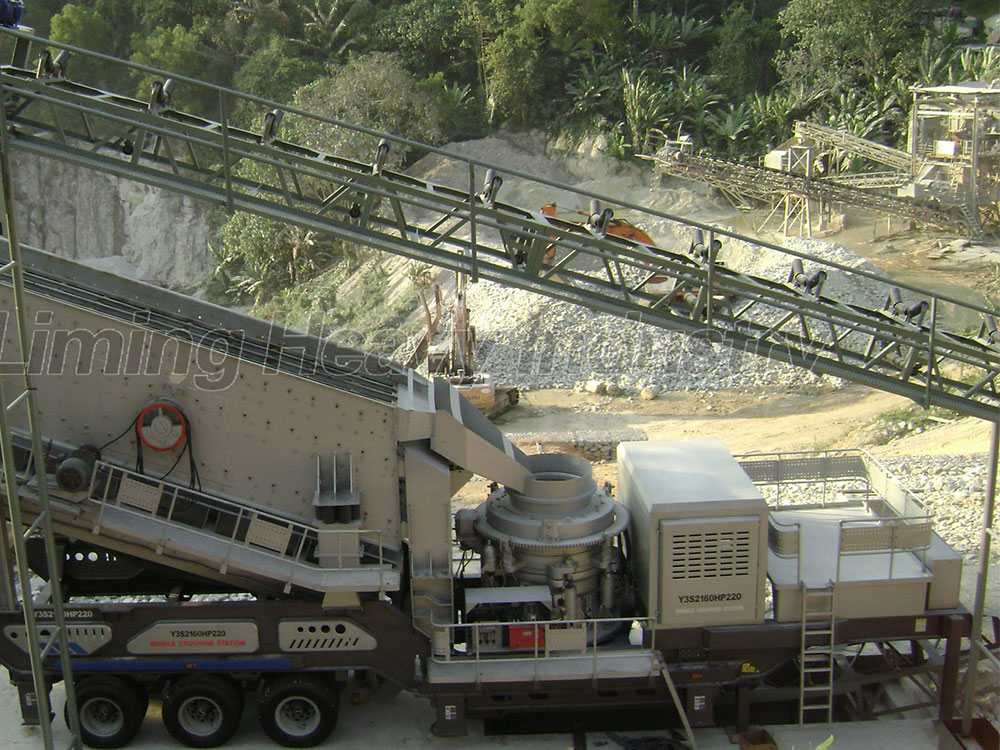

Upon entering the medium and fine crushing stage, we make flexible selections based on the hardness of the raw material. For high-hardness rock materials, we recommend using a mobile cone crusher. This equipment is highly praised for its excellent wear resistance and well-defined discharge particle shape, ensuring precise control of the discharge particle size within the 0-30 millimeter range. For medium-hardness materials, we recommend selecting an impact crusher, such as the PF-1315 model. This equipment not only has excellent processing capacity but also has a shaping effect, which can further optimize the particle size distribution and shape of the finished product. If the production line needs to take into account the production of manufactured sand, we can also consider adding a mobile impact sand making machine to meet the demand for finer particle sizes.

II. Complete auxiliary system

Screening system

In order to achieve fine grading of the finished product, we have configured an efficient multi-layer vibrating screen, such as the 3YK2866 model. This equipment features multiple screening surfaces, enabling the finished product to be divided into multiple specifications such as 0-5 mm, 5-10 mm, 10-20 mm, and 20-30 mm, ensuring compliance with different customers' particle size requirements.

Dust Control Measures

In terms of environmental protection, we have adopted a closed production line design combined with a mist spray system at the material inlet and outlet, effectively controlling dust pollution. These measures not only comply with green mine construction requirements but also help enterprises achieve environmentally friendly development.

Intelligent Management

To achieve intelligent control and rapid relocation capabilities for the production line, we have integrated a modular layout with a central control system. Through this system, operators can monitor the production line's operational status in real-time, adjust parameters promptly, and ensure stable operation. Additionally, the modular layout enables more efficient and convenient relocation of the production line.

III. Application Scenarios and Benefit Assessment

Strong Site Adaptability

This mobile stone production line is suitable for various complex terrains such as mountainous areas and mining sites. Its feature of easy installation without the need for piling allows the production line to be quickly put into operation, significantly shortening the project cycle.

High Return on Investment

By optimizing material transportation processes to reduce intermediate handling steps and transportation costs, the investment payback period of this production line can be shortened by over 30%. This not only enhances the company's economic benefits but also strengthens its market competitiveness.

Green and environmentally friendly standards

In terms of green and environmentally friendly standards, this production line fully complies with relevant requirements. By implementing effective dust control measures and an intelligent management system, we have successfully reduced noise and dust emissions, achieving environmentally friendly development. This not only helps improve the company's social image but also contributes to sustainable development.

This solution ensures the efficient, stable, and environmentally friendly operation of the mobile stone production line by carefully selecting core equipment, improving auxiliary systems, and evaluating application scenarios and benefits.