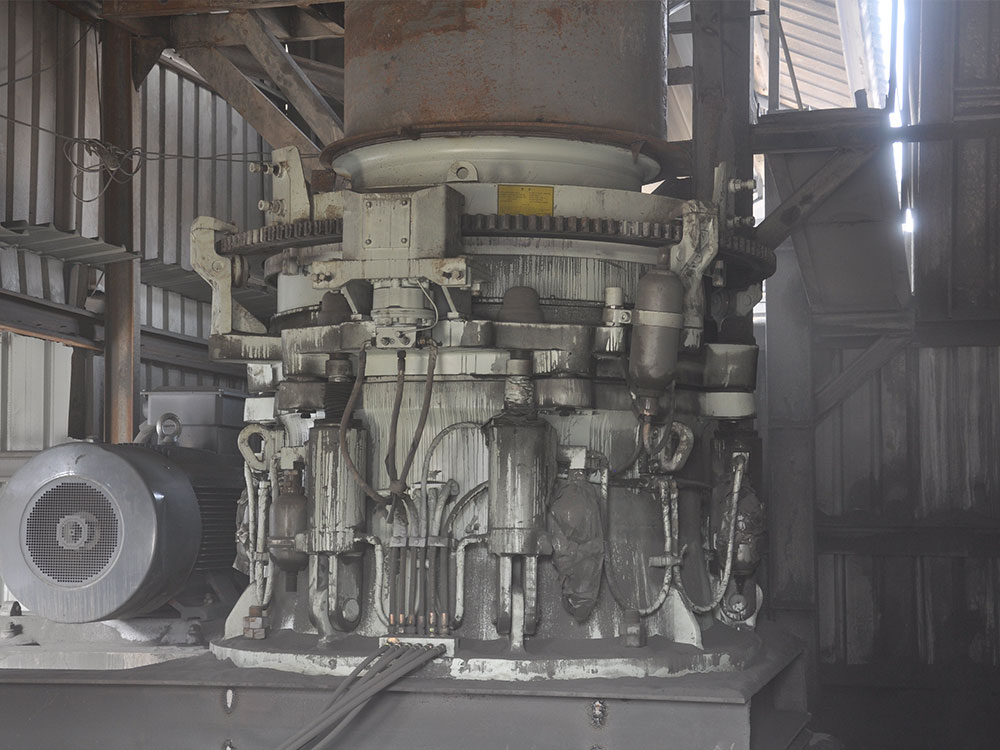

Multi-cylinder hydraulic cone crusher, as the pinnacle of modern crushing technology, has become the leader in the field of hard rock crushing by virtue of its unique lamination crushing concept and cutting-edge hydraulic technology. With its powerful crushing capacity and wide applicability, this equipment is not only able to easily cope with large hard rock with a diameter of up to 30 centimeters and crush it into high-quality 12 or 13 stones, but also particularly suitable for processing materials with extremely high hardness such as granite, basalt and so on, which demonstrates its incomparable technical advantages.

The following are the significant advantages of multi-cylinder hydraulic cone crusher, which make it unique in the market and favored by customers:

First, laminar crushing, outstanding granularity, excellent quality

Multi-cylinder hydraulic cone crusher adopts advanced laminar crushing principle, which realizes full and even crushing of materials through multi-layer extrusion and collision in the crushing chamber. This unique crushing method makes the produced stone show cubic shape, regular particle size, needle-like particles are greatly reduced, the gradation is reasonable and the content of fine powder is moderate. This kind of stone quality not only meets the high requirements of highway, high-speed rail and other high-end projects, but also ensures the stability and durability of the project.

It is worth mentioning that the laminated crushing method also significantly reduces the ineffective friction and the loss of wear-resistant parts. According to statistics, compared with traditional crushing equipment, the energy consumption of multi-cylinder hydraulic cone crusher can be reduced by 20%-30%, and the service life of wear parts can be increased by 30%-50%. This advantage not only saves operating costs for customers, but also improves the overall performance of the equipment.

In practical application, a highway construction project used stones produced by multi-cylinder hydraulic cone crusher. After testing, the quality of these stones fully meets the requirements of the project, and shows good stability and durability in the process of use. This successful case fully proves the excellent performance of multi-cylinder hydraulic cone crusher in laminar crushing.

Intelligent over-iron protection to improve stability and safety

The hydraulic system of the multi-cylinder hydraulic cone crusher is equipped with an intelligent monitoring function, which can monitor the status of the crushing chamber in real time. Once it encounters iron impurities or non-crushable foreign materials, the equipment will automatically lift up the dynamic cone and instantly expand the discharge opening to discharge the foreign materials smoothly. This intelligent protection function effectively avoids potential damage to the core components and greatly improves the stability and safety of the equipment.

In addition, the equipment can be automatically reset after passing the iron, without the need for manual downtime to clear the cavity. This feature not only saves time, but also improves production efficiency. According to the actual case, in a crushing operation, the multi-cylinder hydraulic cone crusher successfully eliminated a number of iron impurities to ensure the smooth progress of the crushing operation. During this process, there was no equipment failure or downtime, saving valuable downtime for the customer.

In order to further enhance the stability and safety of the equipment, the multi-cylinder hydraulic cone crusher also adopts an advanced overload protection device. When the equipment encounters excessive load or abnormal conditions, the overload protection device will automatically activate to protect the equipment from damage. This design enables the equipment to maintain stable operation under adverse working conditions, ensuring the safety and continuity of production.

Intelligent control, flexible configuration, strong adaptability

The multi-cylinder hydraulic cone crusher is equipped with advanced PLC automation system, which can monitor key parameters such as crushing pressure, temperature and vibration in real time. The system will automatically adjust the discharge size and hydraulic pressure according to the actual situation to ensure the stability of the finished product size (e.g. 12/13 gravel). This intelligent control not only improves production efficiency, but also reduces energy consumption. According to statistics, the energy consumption of the equipment can be reduced by 10%-20% after adopting the intelligent control method.

In addition, by replacing the liners of different specifications, the equipment is also able to easily realize the switch between medium and fine crushing modes. This multi-purpose feature makes the multi-cylinder hydraulic cone crusher able to meet the needs of multi-stage crushing, providing customers with more flexible and diversified crushing solutions. For example, in the crushing operation of a large mining enterprise, the multi-cylinder hydraulic cone crusher successfully realizes the comprehensive coverage from coarse crushing to fine crushing by replacing the liners. During this process, the equipment showed good adaptability and stability, greatly improving production efficiency and economic benefits.

In order to further enhance the intelligent level of the equipment, the multi-cylinder hydraulic cone crusher can also be equipped with remote monitoring and fault diagnosis system. Through remote monitoring, customers can understand the operation status and production situation of the equipment in real time; through the fault diagnosis system, customers can quickly locate and eliminate equipment faults to ensure the smooth progress of production. This design makes the equipment reach a new level of intelligence, providing customers with a more convenient and efficient production experience.