For the configuration of a wind-eroded rock crushing and sand-making production line, we have conducted in-depth research and careful planning based on process characteristics and equipment selection criteria, and propose the following detailed configuration plan:

I. Core Process Planning for the Production Line

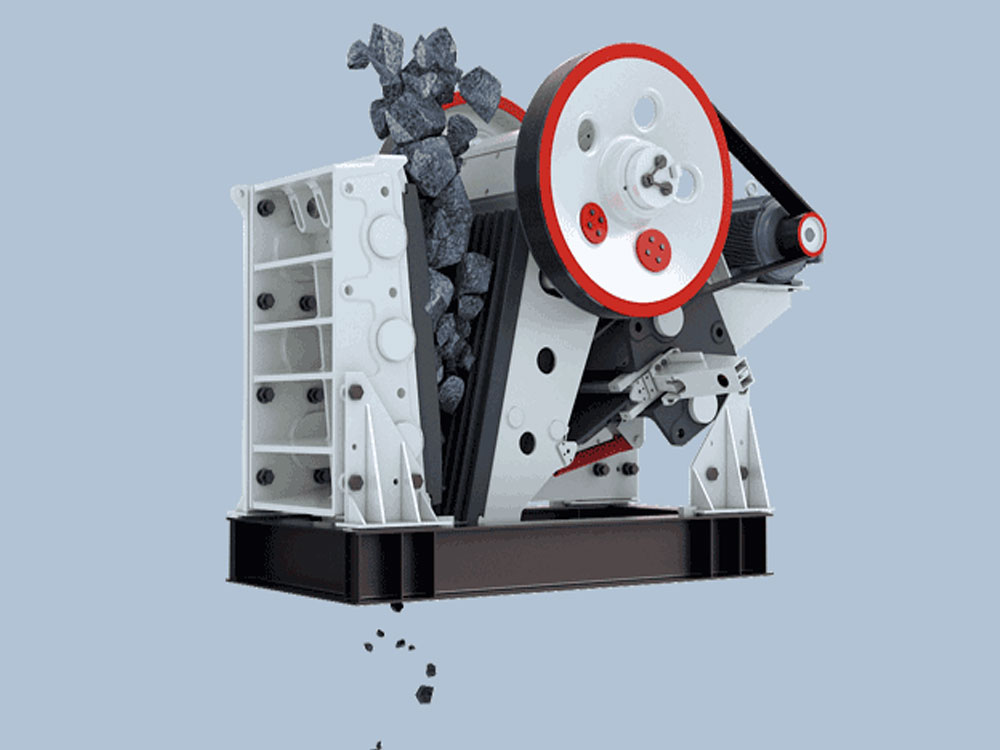

Coarse Crushing Stage

Equipment Recommendations:

Jaw crushers (e.g., CJ series) are particularly suitable for processing weathered rock and other soft rocks due to their excellent adaptability and powerful crushing capacity. These crushers effectively break large pieces of weathered rock into smaller particles during the coarse crushing stage, laying the foundation for subsequent processing steps. The crushing ratio is controlled between 3 and 5 to ensure the crushed material has an appropriate particle size, facilitating subsequent medium and fine crushing processes.

Parameter Configuration:

The motor power must be ≥75 kW to provide sufficient power for crushing operations. The feed particle size must be ≤600 mm to ensure the crusher can handle weathered rock blocks of various sizes. The discharge particle size must be ≤150 mm to meet the feed requirements for the medium and fine crushing stages.

Medium and fine crushing stage

Equipment selection:

Considering the hardness of weathered rock (Mohs hardness 3-4), an impact crusher is the optimal choice. It provides better finished particle shape, reduces needle and flake content, and has relatively low maintenance costs. If higher production is required, a cone crusher (such as a multi-cylinder hydraulic type) is also a viable option, but note that it may increase needle and flake content, affecting finished product quality.

Crushing Ratio Allocation:

The crushing ratio for the medium crushing stage is 4-5, further breaking down the coarse-crushed material into smaller particles. The crushing ratio for the fine crushing stage is 5-8, ensuring the material meets the feed requirements for the sand-making and shaping stages.

Sand-Making and Shaping

Impact Sand-Making Machine (Stone-on-Stone Type):

Suitable for sand-making from weathered rock, it ensures a high proportion of cubic particles, improving the quality of the finished sand. Control the rotational speed (recommended 70 m/s) and feed rate (75%-85%) to ensure sand-making effectiveness and stable equipment operation.

Stone Powder Control:

By configuring a pulse dust collector (dust emissions ≤15 mg/m³), the stone powder content is controlled within the 5%-10% range. This optimizes concrete performance while reducing dust pollution to the environment.

II. Auxiliary System Configuration

Screening System

The YK series circular vibrating screen (double-layer screen mesh) is adopted, which can improve screening efficiency by 18%. The recommended specifications are 20 mm upper screen mesh (for removing oversized particles) and 2.36 mm lower screen mesh (for grading finished sand). This ensures uniform particle size of the screened material, meeting the requirements of various engineering projects.

Sand Washing and Dewatering

Double-spiral sand washer:

Configured in series, with a mud removal rate of ≥98%, and equipped with a thickener to achieve water circulation. This effectively cleans the sand, removing mud and impurities, thereby improving the quality of the finished sand.

Dewatering Screen:

Reduces the moisture content of washed sand to ≤8%, facilitating subsequent transportation and storage.

Environmental Protection and Intelligent Control

Equipped with soundproof enclosures and pulse dust collection systems to minimize noise and dust impact on the environment and personnel. Utilizes PLC systems integrated with IoT technology to achieve fault warning (92% accuracy) and energy consumption optimization. This enhances the automation level and operational efficiency of the production line while reducing maintenance costs.

3. Key Parameter Optimization

Weathered Rock Characteristics Adaptation

If the parent rock strength is <60 MPa (such as weathered rock from sedimentary rocks), the crusher speed should be reduced by 10%-15% to extend the service life of wear parts. This reduces equipment wear and failure rates, improving the stability and reliability of the production line.

When the clay content is high, add a pre-screening stage (vibrating feeder + coarse screen). This can remove clay particles and impurities from the material in advance, reducing the burden and costs of subsequent processing.

Economic Recommendations

For small-scale production lines (50–100 tons per hour), a two-stage crushing process using a jaw crusher + impact crusher + impact breaker can be adopted to reduce investment costs by 30%. This can reduce equipment purchase and maintenance costs while ensuring production quality.

Mobile units are suitable for short-term projects with relocation times ≤4 hours. This enhances the flexibility and adaptability of the production line, meeting the needs of different projects.

IV. Case References

A sand plant in North China

Adopting the “jaw crusher + cone crusher + impact crusher” process, annual output increased by 40%, and the plant was awarded the title of “Green Factory.” This case demonstrates that through reasonable equipment selection and process configuration, production line efficiency and output can be improved while achieving environmental protection and sustainable development goals.

Guangdong Customer

A mobile solution with a production capacity of 200 tons per hour achieved a return on investment within six months, with the key factor being the intelligent lubrication system (bearing lifespan of 12,000 hours). This case showcases the advantages and application effectiveness of mobile units in short-term projects, while emphasizing the importance of intelligent lubrication systems in extending equipment lifespan and reducing maintenance costs.

Notes

Weathered rock has significant fluctuations in clay content, so an online concentration monitoring system must be configured. This enables real-time monitoring of material clay content, allowing timely adjustments to production parameters to ensure stable production line operation.

Avoid using equipment based on the layering principle (e.g., cone crushers) to prevent excessive needle and flake content. Equipment using the layering principle may increase needle and flake content when processing weathered rock, affecting the quality and application effectiveness of the finished sand. Therefore, careful consideration of the crushing principle and suitability of the equipment is necessary during selection.