In the field of construction waste resource utilization, the recycling of cement blocks and gravel has become a key component of the circular economy. Its applications span road construction, concrete production, and building materials, among other areas. Machinery selection and quality control directly impact the performance and economic benefits of recycled materials. The following systematic analysis focuses on three dimensions: crushing equipment selection, recycling application value, and quality control.

I. Crushing Equipment Selection Strategy

1. Conventional Crushing Equipment Suitable Scenarios

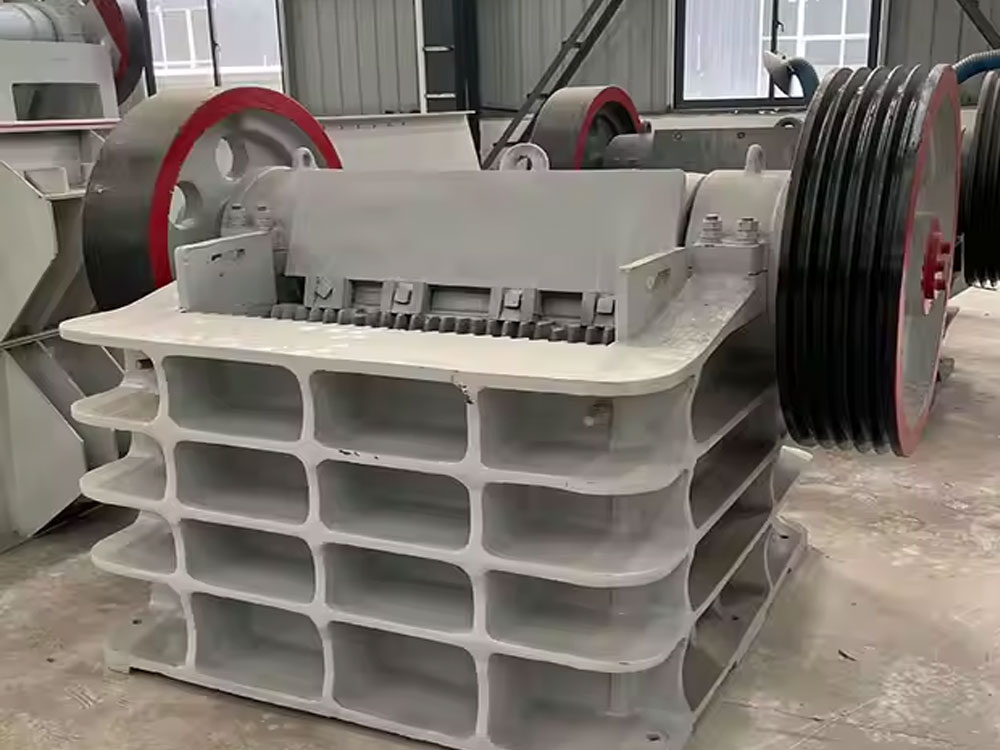

Jaw Crusher: As the core equipment in the primary crushing stage, it offers a crushing ratio of 1:6-1:8 and can crush 1.2m x 1.5m cement blocks to particles smaller than 60cm. For example, in a highway reconstruction project, a single PE900 x 1200 jaw crusher achieved a daily processing capacity of 800 tons, consuming only 18kW·h/t. Its hydraulically adjustable discharge opening (ranging from 50-250mm) allows for precise control of discharge particle size, minimizing over-crushing. Impact Crusher: Fine crushing is achieved through the impact of hammers and collisions with impact plates. The finished product is cubic with less than 10% flake content. In a commercial concrete plant, 5-25mm crushed stone produced by a PF-1315 impact crusher increased the compressive strength of C30 concrete by 8% after 28 days. Its rotor diameter of 1320mm and speed of 750 rpm ensure a balance between efficient crushing and low energy consumption.

2. Innovative Advantages of Mobile Crushing Equipment

Mobile crushing stations integrate feeding, crushing, screening, and conveying. Their crawler-type chassis (climbing capacity ≥ 30°) allows for rapid transport to demolition sites. For example, the Keestrack R6e's diesel-electric dual-drive system reduces energy consumption by 35% and keeps dust emissions below 10mg/m³. In a land clearing project in the Xiongan New Area, the mobile crushing station implemented a closed-loop operation of "on-site crushing - immediate screening - direct reuse," reducing transportation costs by 60%.

II. Exploring the Application Value of Recycled Materials

1. Concrete Preparation Technical Specifications

Crushed recycled aggregate must meet GB/T 25177-2010 standards:

Particle Size Control: Use a continuous gradation of 5-31.5mm, with 5-10mm accounting for 30%, 10-20mm accounting for 50%, and 20-31.5mm accounting for 20%. Tests at a research institute have shown that this gradation improves concrete workability by 15%, achieving 98% of the design 28-day strength.

Mud Content Control: A three-stage cleaning process (pre-washing, scrubbing, and rinsing) can reduce the mud content from an initial 3.2% to 0.8%. In a Shenzhen super-high-rise project, C50 pumpable concrete prepared with cleaned recycled aggregate achieved a 40% lower slump loss rate than natural aggregate.

2. Road Engineering Application Standards

Base Material: 20-40mm crushed stone must meet a CBR value ≥ 80% and a crushing value ≤ 25%. In the Beijing-Shanghai Expressway renovation and expansion project, a base layer composed of 30% recycled crushed stone was used, achieving a 7-day unconfined compressive strength of 4.2 MPa, an 18% reduction in cost compared to traditional materials.

Permeable base layer: By mixing 10-20 mm single-size crushed stone with 5-10 mm fine aggregate in a ratio of 7:3, a water permeability coefficient of 2.5 × 10⁻² cm/s can be achieved, meeting the requirements of sponge city construction.

3. Optimizing the Performance of Building Materials

Permeable bricks: When using recycled aggregate as raw material, the water-cement ratio should be controlled at 0.32-0.35, and the molding pressure should be 15 MPa. Tests have shown that when the recycled aggregate replacement rate reaches 60%, the water permeability coefficient remains at 1.8 mm/s, and the flexural strength reaches 4.5 MPa. Block production: Using vibration pressure molding technology, when the recycled aggregate content is 50%, the block drying shrinkage value is 0.45mm/m, which complies with the GB/T 11968-2020 standard.

III. Key Quality Control Indicators

1. Particle Size and Geometric Properties

Maximum Particle Size Limit: According to JGJ 52-2006, for beam components, the maximum particle size of recycled aggregate must not exceed 1/4 of the beam height and be ≤ 25mm; for slab components, it must not exceed 1/3 of the slab thickness and be ≤ 15mm.

Gradation Optimization: Based on Fuller curve calculations, concrete workability is optimal when the fineness modulus is controlled between 3.0 and 3.5. A project application demonstrated that optimized gradation improved concrete cohesion and reduced segregation by 70%.

2. Hazardous Substance Control

Needle-Flake Content: Image analysis indicates that when the content exceeds 15%, concrete fluidity decreases by 20%. Secondary crushing (jaw crusher + cone crusher) can reduce the needle-flake content from 25% to 12%.

Crushability Index: For concrete below C60, the crushability of limestone should be ≤ 12%, and that of granite ≤ 10%. A nuclear power plant project used recycled granite aggregate with an 8% crushing value, producing C60 concrete with a 28-day strength of 68 MPa.

3. Rock Type Compatibility

Advantages of limestone: Its pH (7.2-7.8) is highly compatible with cement hydration products, and its alkali-aggregate reaction expansion rate is less than 0.05%. In the prefabrication of the immersed tubes of the Hong Kong-Zhuhai-Macao Bridge, C50 marine concrete produced using recycled limestone aggregate achieved a chloride ion permeability resistance of 1.2×10⁻¹²m²/s.

Properties of granite: Its Mohs hardness is 6-7, making it suitable for ultra-high-strength concrete. In the foundation engineering of the Shanghai Tower, C80 concrete produced using recycled granite aggregate achieved an elastic modulus of 38 GPa, a 5% increase over natural aggregate. IV. Technical and Economic Analysis

Take a recycled aggregate production line with an annual output of 500,000 tons as an example:

Equipment Investment: A fixed crushing line (jaw crusher + cone crusher + screening) costs approximately 8 million yuan, while a mobile crushing station combination costs approximately 12 million yuan. However, the mobile system saves 2 million yuan in site preparation costs and 3 million yuan in transportation costs per year.

Operating Costs: The production cost of recycled aggregate is 28 yuan per ton (including crushing, screening, and cleaning), 15 yuan per ton lower than natural aggregate. Assuming a resource tax savings of 3 yuan per ton of recycled aggregate replacing natural aggregate, the annual tax savings is 1.5 million yuan.

Environmental Benefits: Every 10,000 tons of construction waste processed reduces CO₂ emissions by 120 tons and saves 50 tons of standard coal. After implementation, an industrial park project received three-star green building certification and generated 800,000 yuan in annual carbon quota trading revenue.