The complete set of equipment for the sand and gravel production line, as an indispensable and important part of the construction of modern building materials, roads, railways and other infrastructure, its efficient and stable operation is inseparable from the coordinated operation of various key parts. Below, we will discuss these key parts and their importance in detail.

1. Feeding equipment: vibrating feeder

The vibrating feeder, as the "throat" of the sand and gravel production line, is responsible for feeding raw materials such as gravel and sand into the production line evenly and continuously. Its working principle is to throw the material up and move it forward through vibration, thereby realizing the continuous supply of materials. In this process, the vibrating feeder can also perform preliminary coarse screening of the material, remove oversized or undersized particles, and provide more uniform materials for the subsequent crushing process. This continuous and stable supply method not only ensures the stability and continuity of production, but also improves the overall efficiency of the production line.

2. Crushing equipment: jaw crusher, cone crusher, impact crusher

Jaw crusher (jaw crusher)

The jaw crusher is the "strongman" in the sand and gravel production line, mainly used in the coarse crushing stage. Its crushing chamber adopts an optimized design, which can easily handle raw materials with larger feed particle size, such as large stones. Jaw crushers have the characteristics of large crushing ratio, simple structure, stable and reliable operation, so they are widely used in various industries such as building materials, roads, railways, etc. In practical applications, jaw crushers can often significantly improve the crushing efficiency of production lines, reduce energy consumption and operating costs.

Cone crusher

Cone crusher is more suitable for fine crushing and medium crushing stages, and is particularly good at handling materials with higher hardness, such as river pebbles and granite. Its working principle is to crush materials into the required particle size through the extrusion and grinding between the moving cone and the fixed cone. Cone crusher has the characteristics of high production efficiency, long service life, and green environmental protection. In practical applications, cone crusher can often significantly improve the crushing capacity and product quality of production lines.

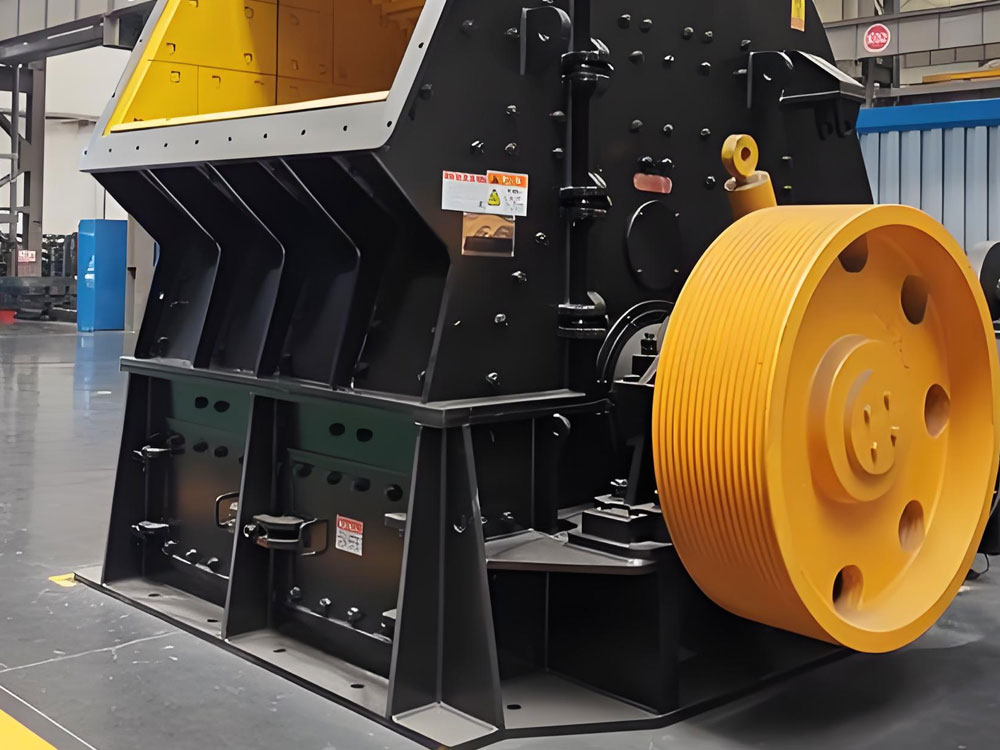

Impact crusher

Impact crusher is one of the commonly used equipment for secondary crushing, and is more suitable for handling materials with lower hardness, such as limestone, bluestone, etc. Its working principle is to crush materials into the required particle size through the impact of the impact plate and the hammer head. The impact crusher has the characteristics of simple structure, easy maintenance, good finished product shape and low investment cost. In practical applications, the impact crusher can often significantly improve the crushing efficiency and product added value of the production line.

3. Screening equipment: circular vibrating screen

The circular vibrating screen is the "screening expert" in the sand and gravel production line. It is mainly used to screen the crushed materials to separate materials of different particle sizes. Its working principle is to use the exciting force generated by the vibration motor to make the screen vibrate, thereby realizing the screening of materials. The screening system is divided into two stages: pre-screening and inspection screening to ensure the efficiency of the production line and product quality. In practical applications, the circular vibrating screen can often significantly improve the screening efficiency and screening accuracy of the production line.

4. Sand making equipment: sand making machine

The sand making machine is the "shaping master" in the sand and gravel production line. Usually, a vertical shaft impact sand making machine is selected. Its working principle is to throw the material up and hit it on the impact plate through the high-speed rotating rotor, thereby realizing the crushing and shaping of the material. Sand making machine has the advantages of small feed particle size, fine discharge particle size, large throughput, long service life, low maintenance cost, and green environmental protection. In practical applications, sand making machine can often significantly improve the sand making efficiency and product quality of the production line, and provide high-quality sand resources for infrastructure construction.

5. Storage and transportation equipment: silos and belt conveyors

Silos and belt conveyors are "logistics experts" in sand and gravel production lines, used to store and transport materials on the production line. Silos are usually designed with steel structures, with large capacity, high strength, and corrosion resistance; belt conveyors use high-quality conveyor belts and drive devices, with long conveying distances, large conveying volumes, and stable and reliable operation. The configuration of these equipment ensures the smooth progress of the production process and improves the overall efficiency of the production line.

6. Dust removal equipment: dust removal system

The dust removal system is the "environmental protection guard" in the sand and gravel production line, including components such as fans, motors, and dust treatment and recovery systems. Its working principle is to use the negative pressure generated by the fan to suck the dust on the production line into the dust collector for treatment; at the same time, the dust is recovered and utilized through the dust treatment and recovery system. The configuration of the dust removal system not only reduces the dust pollution on the production line, protects the environment and the health of workers, but also improves the utilization rate of resources and the economic benefits of the enterprise.

In summary, the complete set of equipment for the sand and gravel production line includes key parts such as feeding equipment, crushing equipment, screening equipment, sand making equipment, storage and transportation equipment, and dust removal equipment. The configuration of these equipment should be comprehensively considered based on factors such as the characteristics of the materials, site conditions, and finished material requirements; at the same time, the selection of well-known brands and reliable quality equipment is also an important factor in ensuring the stable operation of the production line. In practical applications, the efficient and coordinated operation of these equipment will provide high-quality sand and gravel resources for infrastructure construction and promote the sustainable development of the industry.