Granite crushing and screening equipment set of process design

Granite are harder to broken kind material, but are usually more slightly than basalt is easy to be broken. This is because although high hardness granite, but there are certain brittleness. On the design of the crushing process, therefore, can be relatively flexible design, if the market price of the customer have advantages, can use two stage crushing process. However, from the Angle of long-term production, three stage crushing process is still an effective method to reduce the production cost.

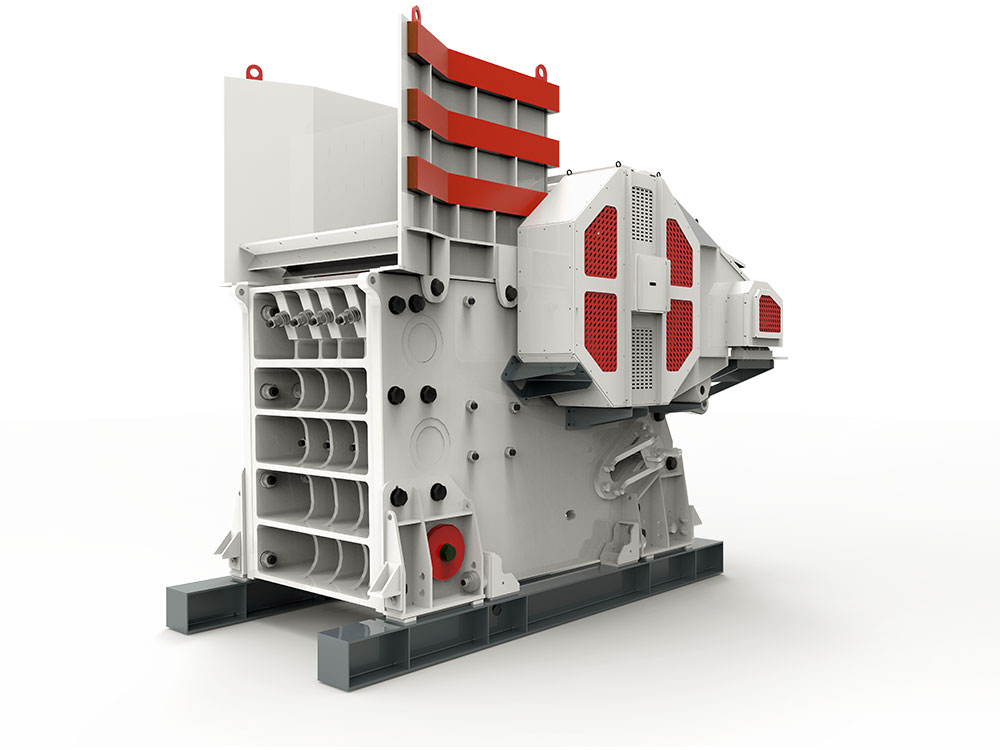

If the customer market of the finished stone grain type request is not high, you can use the two-stage jaw broken solution for production. This configuration is the lowest investment, maintenance maintenance the simplest scheme, the cost of production is also the most economic solution of all. However, the shortcoming of this approach is the stone size and the shape of the poor, higher ratio of needle flake material. The competitiveness of the stone in the market is not high, because of the size and the shape of high-grade construction need excellent stone. In order to improve the grain shape of stone cube (multi), you can use the jaw and back breaking process configuration. This configuration than the above two levels of jaw broken a little high investment cost, production out of the stone granule shape also is very good. However, because of the granite belongs to the more difficult to broken material, counterattack broken wear parts loss is relatively high, long-term production to increase the production cost is considerable. As the granite has the property of brittleness, this configuration is also an acceptable solution.

Require the size and the shape of the products, at the same time could reduce the production cost, so we need to increase between jaw and countering breaking a laminating crushers, such as the use of small jaw broken or cone crusher. This configuration can make the main crushing work finished and breaking end-to-end (laminating crushing), integer by counterattack broken broken at last. This configuration process can greatly reduce the formation of the material after screening. If a production line of the ratio of the material is too high, more will make the final a crusher work repeatedly broken, the corresponding also makes the wear parts loss will increase greatly. Two levels of laminating crushing and third-level counterattack broken process configuration, make investment costs increased, but the production cost greatly reduced. Its advantage is self-evident.

Specific process configuration need according to the actual situation of the specific analysis, welcome to communicate.