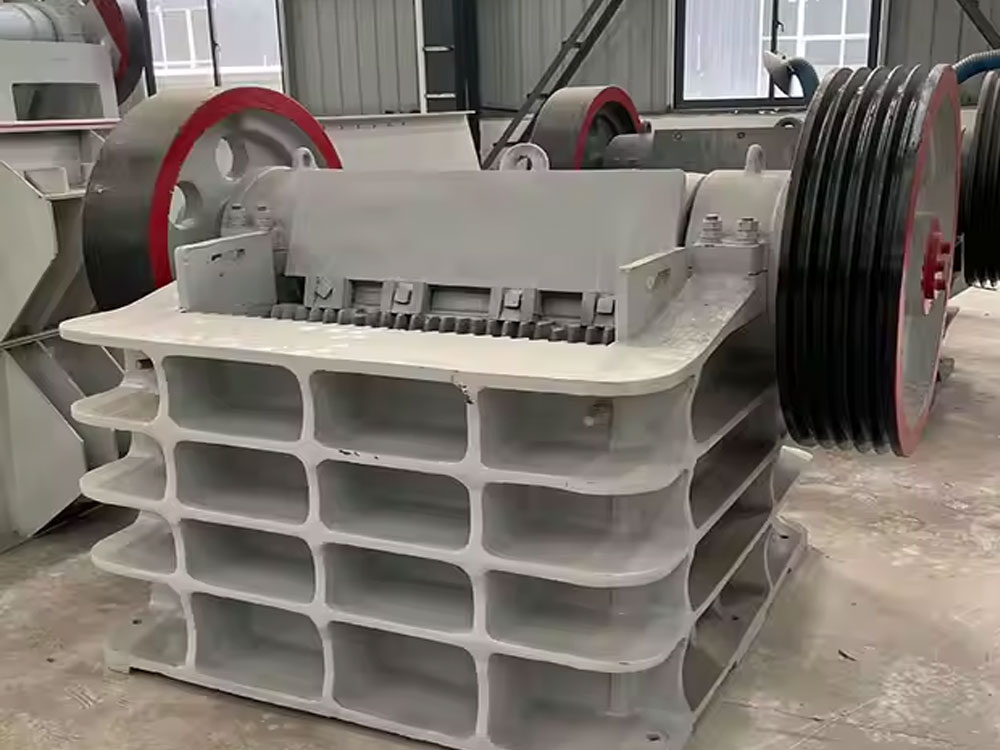

51 Crusher Stone Crushing Equipment

The 51 crusher is a high-performance, high-efficiency medium-sized crushing equipment, mainly used for crushing medium-hard ore, construction waste, coal, stone, etc. It adopts advanced crushing technology and optimized design to ensure its crushing efficiency and working reliability. The design of the 51 crusher takes into account the optimization of the structure and simple operation and maintenance. It uses high-strength components made of high-quality materials, which greatly improves the durability of the equipment. The body structure is sturdy, ensuring that the equipment can operate for a long time in harsh working environments. In actual use, the 51 crusher has shown strong crushing ability. The design of its crushing chamber can effectively improve the crushing efficiency, with a high crushing ratio, and can handle materials with larger particle sizes. At the same time, it ensures that the discharge particle size is uniform and meets different process requirements. Whether it is ore, building materials, or coal, stone, the 51 crusher can easily cope with it. It can adapt to the crushing needs of a variety of materials, especially in production lines, which can effectively improve work efficiency. While ensuring high-efficiency crushing, the 51 crusher focuses on energy saving and consumption reduction, optimizes energy consumption, and reduces operating costs. Its sealing design reduces dust emissions and is more environmentally friendly. The equipment is equipped with an intelligent control system. Operators can easily adjust parameters through touch screens and other devices, monitor the crushing process in real time, and ensure that the equipment operates in the best condition.

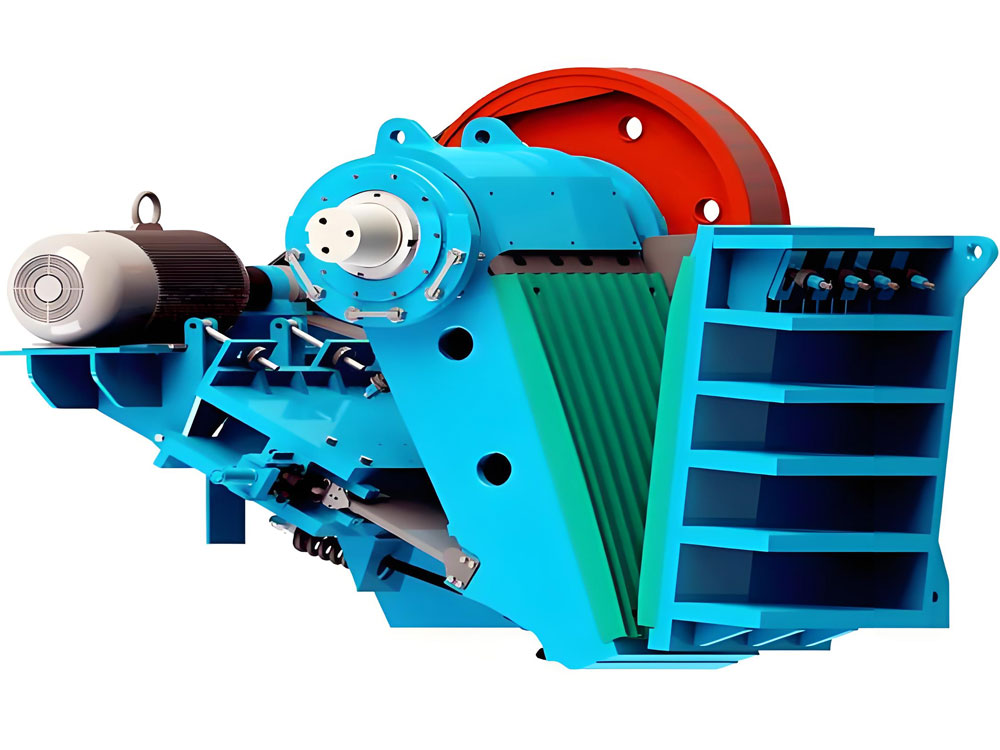

51 Crusher Working Principle

1The crusher mainly uses mechanical energy to break materials into smaller particles. Its working principle is simple and efficient: the material enters the crushing chamber from the feed port of the crusher, and is evenly fed into the crushing chamber through the feeding device of the crusher. In the crushing chamber, the material is clamped by the upper and lower movable crushing plates and the fixed crushing plates. Under the pressure of the crushing plates, the material is crushed into smaller particles. The crushed material is discharged through the discharge port at the bottom of the crushing chamber, and the discharge particle size can be controlled by adjusting the gap between the crushing plates. This ensures that the crushed material meets the required particle size requirements. 51The crusher is equipped with an efficient motor, which drives the movement of the crushing plate through a belt drive device. The motor has high power, ensuring that the equipment can still operate stably under heavy load. The transmission system it adopts reduces the energy loss during equipment operation and improves the crushing efficiency and economy through the cooperation of belts and gears.

51 Crusher Advantages

Efficient crushing performance

With its excellent crushing capacity, the 51 crusher can easily cope with medium-hard to high-hardness materials such as ore, construction waste, coal and stone. The equipment can complete the crushing of materials in a shorter time through the optimized crushing chamber design and efficient crushing mechanism, greatly improving the output of the production line. The large crushing ratio can effectively reduce the particle size of the material to ensure the discharge particle size that meets the project requirements. In addition, the equipment can also maintain high stability when processing large pieces of material, avoiding the problems of jamming and reduced efficiency of traditional crushers due to excessively large materials.

Energy-saving and environmentally friendly design

While ensuring strong crushing force, the 51 crusher adopts advanced energy-saving technology to reduce energy consumption. The design of the equipment reduces friction and transmission system losses, making the energy consumption during operation lower and the energy efficiency better than traditional equipment. At the same time, the sealing design of the crusher greatly reduces the leakage of dust, meets modern environmental protection requirements, reduces the impact on the surrounding environment, and reduces the potential threat to workers' health. For projects that require strict control of dust emissions, the 51 crusher is an ideal choice.

Strong and durable structure

The 51 crusher is made of high-strength steel, and the overall structure is strong and durable, which can work stably for a long time in harsh environments. The crushing chamber and main components are designed to meet the requirements of high-strength loads, and are not prone to wear and damage, which extends the service life of the equipment. By adopting high-quality wear-resistant materials and precision manufacturing processes, the 51 crusher can still maintain good working condition under high-load operation, reducing the need for frequent maintenance and parts replacement, and reducing operating costs.

Easy maintenance and convenient operation

The design of the 51 crusher focuses on the convenience of operation and maintenance. The equipment is equipped with an advanced intelligent control system. The operator can easily adjust the crushing parameters through a simple interface, monitor the status of the equipment in real time, and ensure that it is always in the best working condition. In terms of maintenance, the 51 crusher adopts a modular design, and important components are easy to disassemble and replace, reducing downtime and maintenance difficulty. The equipment is equipped with an automatic lubrication system, which reduces the need for manual intervention and ensures the smooth operation of the equipment during long-term operation.

Wide applicability and flexibility

The 51 crusher was designed with a variety of operating environments and material diversity in mind, and has a wide range of adaptability. Whether it is ore, coal, stone, construction waste, concrete blocks, etc., the 51 crusher can efficiently complete the crushing task. Especially when processing materials of different hardness, the 51 crusher can flexibly control the discharge particle size by adjusting the gap between the crushing plates to meet the needs of different projects and production lines. In addition, the equipment has a compact structure and is suitable for a variety of installation methods. It can adapt to production lines of different sizes, providing users with more choices and flexible application solutions.

51 Crusher Technical parameters

| Feed size | ≤500mm | Motor power | 37-75kW |

| Discharge size | 10-100mm | Crushing chamber type | deep chamber type |

| Processing capacity | 50-120t/h | Overall dimensions | 2900×2200×2500mm |

51 Crusher Cases and customer reviews

On a domestic construction site, a customer used a 51 crusher for concrete gravel recycling. After a period of use, the customer reported that its crushing efficiency was significantly improved, the crushing effect was stable, and the output particle size was uniform, which fully met the production requirements.

"The equipment we used before had unstable crushing effect and often broke down. Since the replacement of the 51 crusher, not only has the production efficiency been greatly improved, but the equipment has also run stably and the maintenance cost has been greatly reduced." said the head of a mining company.

The customer also mentioned that the 51 crusher has a friendly operating interface and is easy to maintain, making it easier for operators to work. The high-efficiency and energy-saving characteristics of the equipment also reduce the operating costs of the factory and play a positive role in reducing environmental pollution.

These customer reviews provide strong evidence for the stability and high-efficiency performance of the 51 crusher, further consolidating its leading position in the market.