Adjustment of Discharge Size of NW106 Jaw Crusher

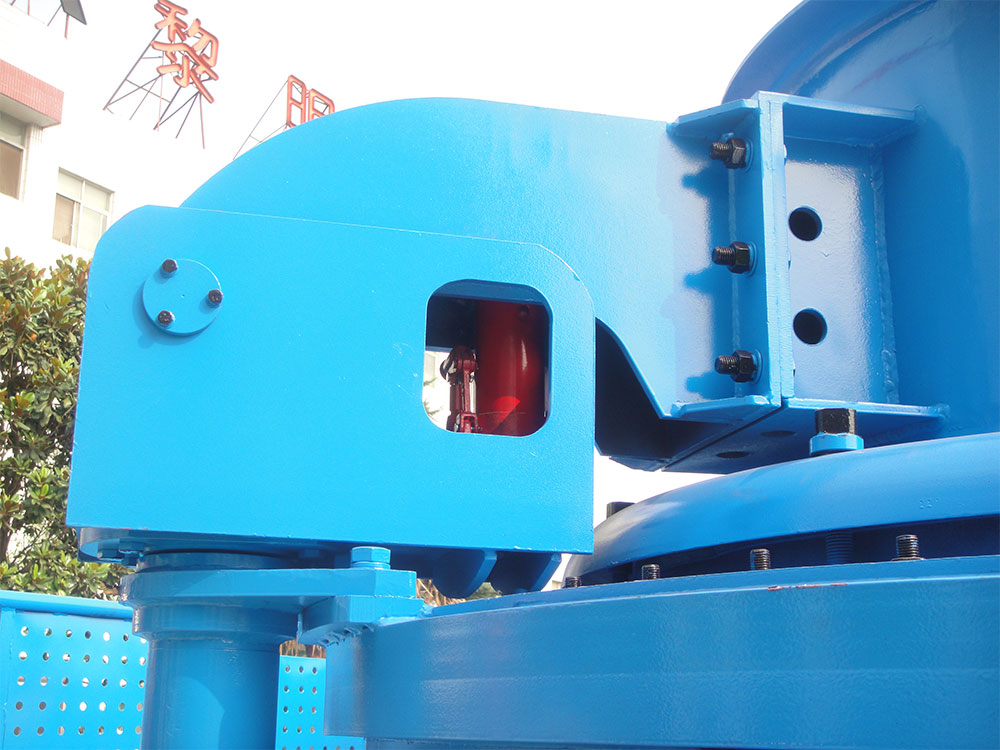

The NW106 Jaw Crusher, with a crushing power of up to 110kW (150hp) and an even more impressive capacity of up to 250tph (tons per hour). This crusher adopts the design of pin-bolt connection and non-welded frame structure, which gives it excellent fatigue strength, and it can easily cope with both hard and soft rocks, as well as recycled materials, such as granite, basalt, limestone and even concrete.

What's more, the NW106 Jaw Crusher can be equipped with a variety of optional accessories according to customer's actual needs, such as hydraulically adjustable legs, hopper side plates, main conveyor and side conveyor, etc., and can be easily installed without the need for a heavy-duty crane. In addition, the optional crushing hammer and electromagnetic separator provide a strong guarantee for removing metal from the final product.

The NW106 jaw crusher also excels in terms of design features. A flywheel guard made of composite material, a spacious maintenance platform and maximum accessibility make daily operation safer and easier. The support of Metso's global service and optimization experts, as well as the timely delivery of high-quality spare and wear parts, add unlimited value to this crusher. Whatever your process needs, the NW106 jaw crusher can be customized to meet them.

Adjustment of Discharge Size of NW106 Jaw Crusher Applications

The NW106 Jaw Crusher is a powerful piece of equipment that is widely used in a variety of fields such as mining engineering, construction material production, road engineering and recycling. In mining, it can easily meet the challenge of crushing all kinds of hard ores and rocks into appropriate sized particles, providing ideal raw materials for subsequent processes.

For the production of building materials, the NW106 jaw crusher is also an indispensable piece of equipment. It is capable of crushing limestone, granite and other raw materials into the required particle size to meet the production requirements of concrete, mortar and other building materials. At the same time, the equipment is also able to crush construction waste and turn it into reusable recycled materials, which promotes the sustainable development of the construction industry.

In road projects, NW106 jaw crusher plays a pivotal role. It is capable of crushing various kinds of stone materials and providing high quality roadbed and pavement laying materials for highways, railroads and other road projects. Its efficient and stable working performance ensures the smooth progress of the project and improves the quality of road construction.

In addition, NW106 Jaw Crusher also shows its great strength in recycling materials. It is able to crush waste concrete, bricks and other wastes, realizing the reuse of resources and reducing environmental pollution. Meanwhile, in the fields of chemical industry and metallurgy, this equipment also has a wide range of application prospects, providing stable and reliable raw material guarantee for production.

Adjustment of Discharge Size of NW106 Jaw Crusher Advantages

Withstand strong impact

Split welded cast steel frame with simple structure and strong impact resistance; Heavy duty eccentric shaft and bearings ensure the impact resistance of the movable jaw assembly; Heavy duty guard plate is mounted on top of the movable jaw to withstand the strong impact of materials.

High-quality Material Finishing

The jaw plate and side guards are made of high manganese steel, the elbow plate is made of gray cast iron, and the eccentric shaft is made of high-strength forged steel, which are made after many times of precision machining, heat treatment and flaw detection inspection, and have sufficient rigidity and strength.

Overload protection mechanism

When the equipment is working, there may be more materials than its crushing capacity into the material, these materials will have adverse effects on the operation of the equipment, and even damage the equipment, at this time, the elbow plate will break by itself to protect the equipment from damage.

Easy to Operate and Maintain

NW106 Jaw Crusher adopts advanced automatic control system, which makes the operation and maintenance of the equipment easy and safe. The machine is also equipped with a touch-screen control system, making it easy for users to make real-time monitoring and adjustments. In addition, the strong support of Metso's global service and optimization experts, as well as the timely delivery of high-quality spare parts and wear parts, provide a strong guarantee for stable operation and efficient maintenance.

Flexible configuration options

The machine can be equipped with a wide range of accessories, such as hydraulically adjustable legs, hopper side panels, main conveyor and flank conveyor, according to the customer's actual needs. These options not only improve the flexibility and adaptability of the equipment, but also provide customers with a more convenient and efficient operation experience.

Adjustment of Discharge Size of NW106 Jaw Crusher Working Principle

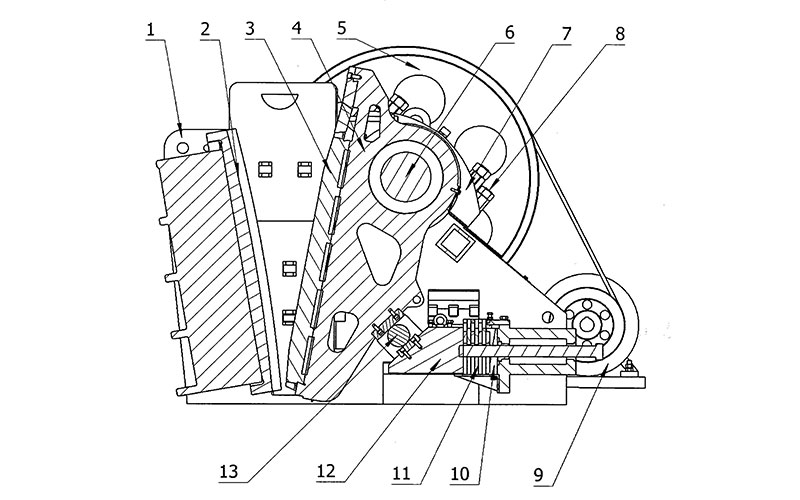

Jaw crusher, this equipment mainly consists of frame, eccentric shaft, large pulley, flywheel, side guards, elbow plate, elbow plate back seat, clearance screw, reset spring, fixed jaw plate and movable jaw plate and other key components. The crushing method is unique and adopts the principle of curvilinear extrusion.

When working, the motor drives the belt and pulley to rotate, which in turn drives the movable jaw to move up and down through the eccentric shaft. When the movable jaw rises, the angle between the elbow plate and the movable jaw gradually increases, which pushes the movable jaw plate closer to the fixed jaw plate. At this time, the material is squeezed and rubbed between the two jaw plates to realize crushing. When the movable jaw moves downward, the angle between the elbow plate and the movable jaw becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the tie rod and spring. At this time, the crushed material will be discharged freely through the discharge opening at the lower part of the jaw cavity under the action of gravity.

With the continuous rotation of the motor, the movable jaw periodically crushes and discharges the material, thus realizing efficient mass production. Such working principle and structural composition make the jaw crusher widely used in many fields.

Adjustment of Discharge Size of NW106 Jaw Crusher Technical Parameters

| length | 13,482 mm | width | 3,130 mm |

| height | 4,117 mm | weight | 34,000 kg |

| Feed opening | 1 060 mm x 700 mm | power | 110 kW |