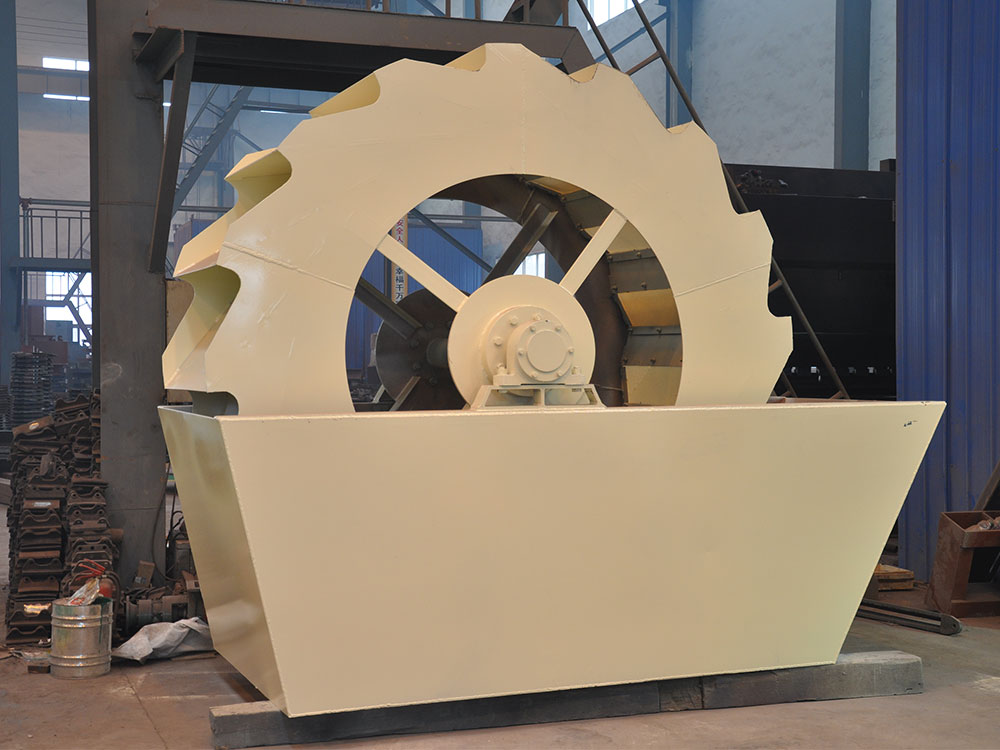

Best industrial sand scrubber for heavy-duty cleaning

Scrubber 1200 sand washing machine is a professional sand and gravel cleaning equipment, widely used in construction engineering, mining development, sand and gravel plants and other fields. This equipment is mainly used to remove soil, dust and other impurities from sand and gravel, thereby improving the purity and quality of the sand and gravel to ensure that it meets the strict standards of the project. This sand washing machine is famous for its high efficiency and stability. Its core structure adopts a drum-type design, combined with a powerful stirring function, which can effectively separate the attachments in the sand and gravel. The equipment shell and key components are made of wear-resistant materials and can operate stably for a long time in complex environments. With its super cleaning ability and large processing capacity, Scrubber 1200 is particularly suitable for medium and large sand and gravel processing plants, significantly improving production efficiency for users. Another highlight of the Scrubber 1200 is its environmentally friendly performance. By optimizing water resource utilization and matching sewage treatment systems, it minimizes wastewater discharge and complies with modern environmental protection standards. In addition, the equipment adopts a modular design, and users can flexibly customize equipment parameters, such as cleaning intensity and screen specifications, according to production needs to meet the requirements of different working conditions. Taken together, the Scrubber 1200 sand washing machine has become an ideal choice in the field of sand and gravel cleaning due to its high efficiency, durability and environmental protection. It is the best choice to improve the efficiency and quality of sand and gravel processing.

Best industrial sand scrubber for heavy-duty cleaning Advantages

Excellent cleaning results

The Scrubber 1200 adopts a drum design and is equipped with a powerful stirring function, which can effectively remove soil, adherents and organic impurities in sand and gravel, ensuring the cleanliness and quality of the sand and gravel, and greatly increasing the market value of the final product.

Large processing capacity to meet high production needs

This equipment can process 100-200 tons of sand and gravel per hour, which is very suitable for the production needs of medium and large sand and gravel plants. Efficient cleaning capabilities not only improve production efficiency, but also significantly reduce unit processing costs.

Sturdy and durable, long life

The equipment is made of high-strength and wear-resistant materials and can withstand high-load operating conditions. Whether it is used frequently or in complex working conditions, Scrubber 1200 can maintain long-term and stable performance and reduce the frequency of maintenance due to wear.

Energy saving and environmental protection, in line with modern standards

Energy saving and consumption reduction were fully considered in the design, and the water resource utilization rate of the equipment was optimized. It was also equipped with a sewage circulation treatment system to significantly reduce wastewater discharge and reduce the impact on the environment, which is in line with the contemporary green production concept.

Flexible customization to adapt to various needs

Scrubber 1200 has a modular design and can adjust parameters such as screen aperture and cleaning intensity according to the specific requirements of customers to adapt to different types of sand and gravel cleaning needs and provide users with more personalized solutions.

Simple to use and easy to maintain

The equipment is easy to operate and has a high degree of automation. Users can get started quickly without excessive training. The design pays attention to the convenience of maintenance, and the replacement of wearing parts is simple, reducing downtime and maintenance costs.

Widely applicable and universal in the industry

Whether it is cleaning construction sand, mining sand and gravel or industrial sand and gravel, the Scrubber 1200 can do the job. Its strong versatility makes the equipment suitable for multiple industries and scenarios.

Stable operation and reduced risk of failure

Under high-load operating conditions, Scrubber 1200 performs well and has extremely high operational stability. Its reliable performance can effectively reduce the risk of equipment failure, thereby ensuring the continuity of the production line.

Professional after-sales service, worry-free use

Scrubber 1200 is equipped with a complete after-sales service system, which can respond quickly from technical support to parts supply to ensure that users' equipment is always in optimal operating condition.

Best industrial sand scrubber for heavy-duty cleaning Working Principle

First, the material enters the drum, and the raw materials are evenly fed into the drum cleaning area through the feeding equipment. Special stirring blades and lifting devices are set inside the drum to flip and push the sand and gravel to ensure that the material is fully exposed to the water flow during the cleaning process. Then it is efficiently cleaned and separated. As the drum rotates, the sand and gravel are subjected to strong stirring and friction in the drum, and the soil and impurities attached to the surface of the sand and gravel are washed and separated by the water flow. At the same time, the equipment classifies sand and gravel of different particle sizes through a grading screen. Secondly, sewage discharge and recycling, the sewage generated during the cleaning process is discharged through the drain at the bottom of the equipment and enters the circulation treatment system. After filtration and sedimentation treatment, the clean water can be returned for use again, thereby reducing the waste of water resources. Finally, the clean sand and gravel are discharged, and the cleaned sand and gravel are discharged from the discharge end of the equipment and sent to subsequent processes or used directly to ensure that the high standards of sand and gravel quality requirements are met.

Best industrial sand scrubber for heavy-duty cleaning Technical parameters

| Output | 100-200t/h | Discharge size | 0-50mm |

| Model | Scrubber 1200 | Motor power | 22-55kw |

| Drum diameter | 1200mm | Cleaning medium | water |

Best industrial sand scrubber for heavy-duty cleaning Technical parameters Cases and customer testimonials

Cases and customer testimonials

Saudi Arabia is located in the Middle East, and its abundant sand and gravel resources provide sufficient raw materials for infrastructure construction and mining development. However, due to the high content of soil and impurities in sand and gravel, direct use will affect the quality of the project and must be efficiently cleaned and classified. Therefore, a large local construction company introduced the Scrubber 1200 sand washing machine for cleaning and grading construction sand and gravel.

Project Overview

Location: Suburbs of Riyadh, Saudi Arabia

Equipment: Scrubber 1200 sand washing machine

Processing capacity: 150 tons per hour

Application scenarios: Used for high-quality sand and gravel cleaning required for large-scale construction projects, including the construction of highways, bridges and residential projects.

Equipment installation and debugging

The screen aperture and drum speed are customized according to project requirements to ensure that the particle size of the washed sand meets engineering standards.

Conduct on-site water resource assessment before equipment operation, and equip with a sewage treatment system to achieve recycling of water resources.

Operation and effect

Cleaning quality: The content of soil and impurities in the sand and gravel is significantly reduced, and the cleanliness reaches more than 98% of the project requirements.

Efficiency performance: It can operate stably for more than 10 hours a day, meeting the high-intensity needs of the project.

Environmental protection effect: The sewage treatment system recycles the wastewater generated during the cleaning process and reuses it, saving nearly 40% of water consumption.