Best Jaw Crusher for Granite: Top Picks & Buying Guide (2025)

Granite is one of the hardest natural stones, requiring a robust and efficient jaw crusher for optimal crushing performance. Whether you're in mining, construction, or aggregate production, choosing the best jaw crusher for granite ensures high productivity, durability, and cost-effectiveness.

In this guide, we’ll explore:

✔ Key features to look for in a granite jaw crusher

✔ Top 5 jaw crushers for granite crushing

✔ Maintenance tips to extend crusher lifespan

✔ FAQs on granite crushing solutions

Why Choose a Jaw Crusher for Granite?

Granite has high compressive strength (100-250 MPa) and abrasiveness, making it challenging to crush. A jaw crusher is ideal because:

✅ High Crushing Efficiency – Jaw crushers apply compressive force, effectively breaking down granite.

✅ Durable Construction – Heavy-duty manganese steel jaws resist wear.

✅ Adjustable Output Size – Control the final product size (20-150mm) for different applications.

✅ Low Operational Cost – Fewer moving parts reduce maintenance expenses.

Alternative machines like impact crushers wear out faster when processing granite.

Key Features to Look for in a Granite Jaw Crusher

When selecting the best jaw crusher for granite, consider these critical factors:

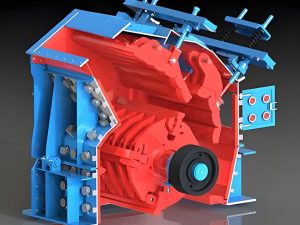

A. Strong Jaw Plates

Material: High manganese steel (Mn18Cr2) for extended durability.

Design: Optimized tooth profile for better grip and crushing action.

B. Powerful Motor & Crushing Force

Motor Power: 30-400 kW (depending on crusher size).

Crushing Capacity: 50-1,500 tph (for large-scale operations).

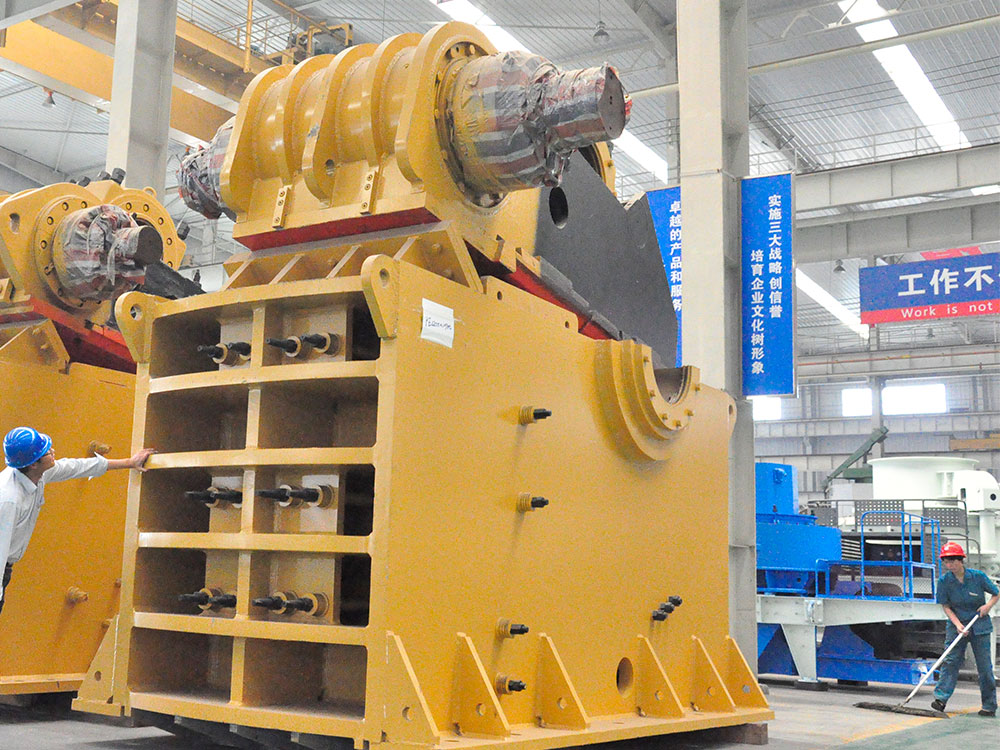

C. Sturdy Frame & Eccentric Shaft

Reinforced steel frame to handle high stress.

Precision-balanced eccentric shaft for smooth operation.

D. Hydraulic Adjustment System

Allows quick setting changes for different output sizes.

How to Optimize Jaw Crusher Performance for Granite?

A. Proper Feeding Technique

Avoid oversized rocks (>80% of inlet size).

Use a vibrating feeder for consistent material flow.

B. Regular Jaw Plate Inspection

Check for wear every 200-300 operating hours.

Rotate or replace jaws when worn to maintain efficiency.

C. Lubrication & Bearing Maintenance

Use high-temperature grease for bearings.

Monitor oil levels in hydraulic systems.

D. Optimal Discharge Setting

Adjust the closed-side setting (CSS) based on required output size.

Common Problems & Solutions When Crushing Granite

❌ Problem: Excessive wear on jaw plates

✅ Solution: Use Mn18Cr2 alloy jaws & reduce unbreakable material entry.

❌ Problem: Low production capacity

✅ Solution: Check feed size uniformity & adjust CSS.

❌ Problem: Vibrations & noise

✅ Solution: Inspect foundation bolts & replace worn bearings.

FAQs: Best Jaw Crusher for Granite

Q1. Can a jaw crusher crush granite?

Yes, jaw crushers are ideal for granite due to their high compressive force.

Q2. What is the best jaw plate material for granite?

Manganese steel (Mn18Cr2) offers the best wear resistance.

Q3. How much does a granite jaw crusher cost?

Small units: $30,000 - $100,000

Large industrial crushers: $200,000 - $500,000+

Q4. What is the lifespan of a granite jaw crusher?

With proper maintenance, 10-20 years (depending on usage).

Conclusion: Choosing the Best Jaw Crusher for Granite

The best jaw crusher for granite should have:

✔ High manganese steel jaws for wear resistance

✔ Strong motor & crushing capacity (200+ tph for commercial use)

✔ Easy maintenance & hydraulic adjustment