C200 jaw crusher discharge size adjustment

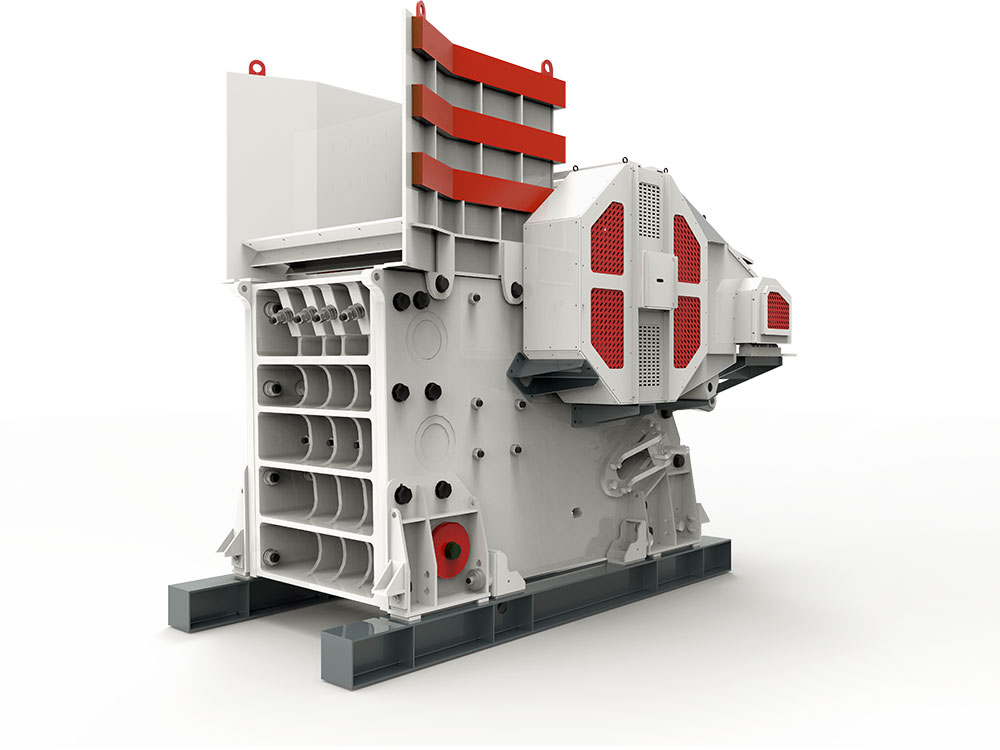

The C200 jaw crusher is Metso's top-of-the-line crushing equipment designed for use in very large-scale mines and quarries. It is known for its excellent performance and reliability. This crusher has powerful crushing capacity and is particularly suitable for processing hard and highly abrasive materials such as granite, basalt and iron ore. With its extra-large feed opening (2000 x 1500 mm), the C200 can easily accommodate large materials, greatly improving production efficiency and providing strong support for high-volume needs. The C200 adopts a solid structural design and is manufactured with high-quality materials. It can operate stably for a long time in extreme working environments, and its impact resistance and durability are particularly outstanding. The optimized modular design of the equipment not only improves installation flexibility, but also simplifies the maintenance process and makes replacement of parts more convenient, thereby effectively reducing equipment downtime and improving overall production efficiency. In addition, C200 pays attention to the convenience of user operation, and ensures a safe and reliable operation process through carefully designed operating mechanisms and safety protection functions. This crusher is widely used in open pit mines and large quarries and is particularly suitable for projects requiring high throughput, such as infrastructure construction or mineral mining. With its high performance, long life and reliability, C200 has become the ideal choice for large-scale industrial crushing needs, fully demonstrating Metso's technical strength and industry leadership in the field of crushing technology.

C200 jaw crusher discharge size adjustment Benefits

Large feed capacity

The C200 is equipped with a large feed opening of 2000 x 1500 mm, which can easily handle large-sized materials. This design makes it particularly suitable for processing hard and large rocks such as granite, basalt and iron ore, meeting the needs of large mines and quarries.

High output and high efficiency

This equipment is designed with a focus on high throughput to meet the needs of high-output operations. Whether it is an open-pit mine or a large infrastructure project, the C200 can maintain a continuous and stable crushing capacity, greatly improve production efficiency, and ensure that strict production targets are met.

Rugged and durable structure

Made of heavy-duty steel structure and high-quality wear-resistant materials, the C200 has strong impact and wear resistance and can maintain excellent performance for a long time even in harsh working conditions. It is designed with special considerations for high-intensity and high-pressure working environments, making it an ideal choice for long-term durability.

Easy maintenance

The modular design of the C200 simplifies the installation and maintenance process. The easy replacement of key components and high maintenance efficiency help reduce unplanned equipment downtime, thereby improving overall operating efficiency. The equipment has a longer maintenance interval, which greatly reduces operating costs.

Excellent safety design

This crusher is equipped with a variety of advanced safety features, including an easy-to-operate control system and a safety lock device, which effectively reduces the risk of human operating errors and ensures the safety of operators.

Excellent environmental performance

C200 optimizes energy consumption performance, reducing energy consumption while maintaining high efficiency. In addition, the equipment generates less noise and dust during operation, which is more in line with modern industrial environmental protection requirements.

Wide range of applications

C200 can not only meet the needs of large quarries and open-pit mines, but also perform well in demanding industrial projects. It is highly adaptable and can handle a variety of hard or abrasive materials, making it the best choice for high-intensity operations.

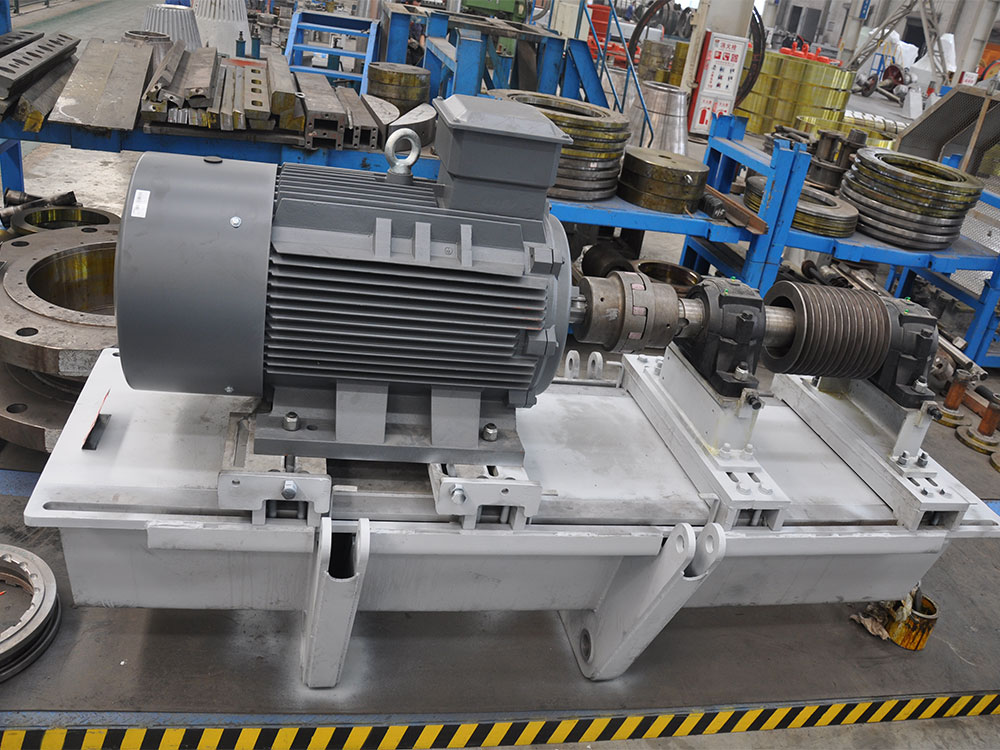

C200 jaw crusher discharge size adjustment Working Principle

The working principle of the C200 jaw crusher is based on the classic crushing mechanism, which achieves material crushing through the relative movement between the movable jaw and the fixed jaw. After the equipment is started, the motor drives the flywheel and eccentric shaft to rotate through the belt, and then drives the movable jaw to swing back and forth along the predetermined trajectory. When the material is fed into the feed port, it falls into the crushing chamber between the movable jaw and the fixed jaw. In the process of the movable jaw approaching the fixed jaw, the material is squeezed and crushed, and gradually crushed into smaller particles. At the same time, when the movable jaw moves away from the fixed jaw, the crushed material is discharged through the discharge port under the action of its own gravity. The depth and cavity design of the crushing chamber are optimized to ensure that the material is evenly stressed throughout the crushing process, thereby improving the crushing efficiency and the quality of the finished product. C200 adopts a high-performance eccentric shaft and flywheel structure to ensure the smooth movement of the movable jaw, reduce equipment vibration, and optimize energy consumption. Its unique crushing chamber structure design not only improves the material passing capacity, but also reduces the possibility of material blockage. In addition, the device supports the adjustment of the discharge port size to meet the production needs of different particle size requirements. This working principle combined with Metso's advanced technology enables the C200 to perform excellently when processing hard and abrasive materials, and is widely used in high-intensity crushing operations in large mines and quarries.

C200 jaw crusher discharge size adjustment Technical parameters

| Output | 800-1000t/h | Discharge size | 150-250mm |

| Feed port size | <1500mm | Motor power | 250-400 kW |

| Feed particle size | 1500mm | Weight | 120-140t |

C200 jaw crusher discharge size adjustment Cases and customer reviews

The application case of C200 jaw crusher in Libya demonstrates its excellent performance and adaptability in extreme environments. Libya's mines and quarries are famous for their abundance of hard rocks such as granite and basalt. At the same time, extreme climatic conditions and harsh operating environments place extremely high requirements on the reliability and durability of equipment. In this project, C200 was used in a large stone processing plant, whose main task was to crush high-hardness stones used in infrastructure construction. The project has strict requirements on production efficiency and continuous working capacity of the equipment. With its ultra-large feed opening of 2000 x 1500 mm and high throughput characteristics, the C200 can easily cope with the processing needs of large-sized materials, and the average daily output has been significantly increased. The equipment shows excellent stability during operation and can maintain efficient operation even under adverse conditions such as high temperature and dust. Its modular design makes on-site installation and maintenance more convenient, effectively shortening downtime. In addition, by adjusting the discharge port, the equipment successfully meets the production needs of different particle sizes, ensuring the flexibility of the project.

“First of all, its super-large feed inlet design is indeed very practical and can easily handle large materials without the need for additional pre-processing equipment, which greatly improves our production efficiency. Secondly, this machine’s crushing capacity is very strong. The average output has increased by more than 30% compared to our original equipment, while the energy consumption has remained within a reasonable range, which makes me very confident about the control of operating costs. "

"In terms of maintenance, the C200 adopts a modular design, which makes it particularly convenient to replace parts and reduces maintenance time. Most importantly, its operation is very stable. Even in the high temperature and high dust environment of our mine, it has never had any problems. Excessive failure problem. Compared with the equipment used in the past, the reliability and lifespan of the C200 are obviously better. ”