CH860i crusher cone design is more powerful

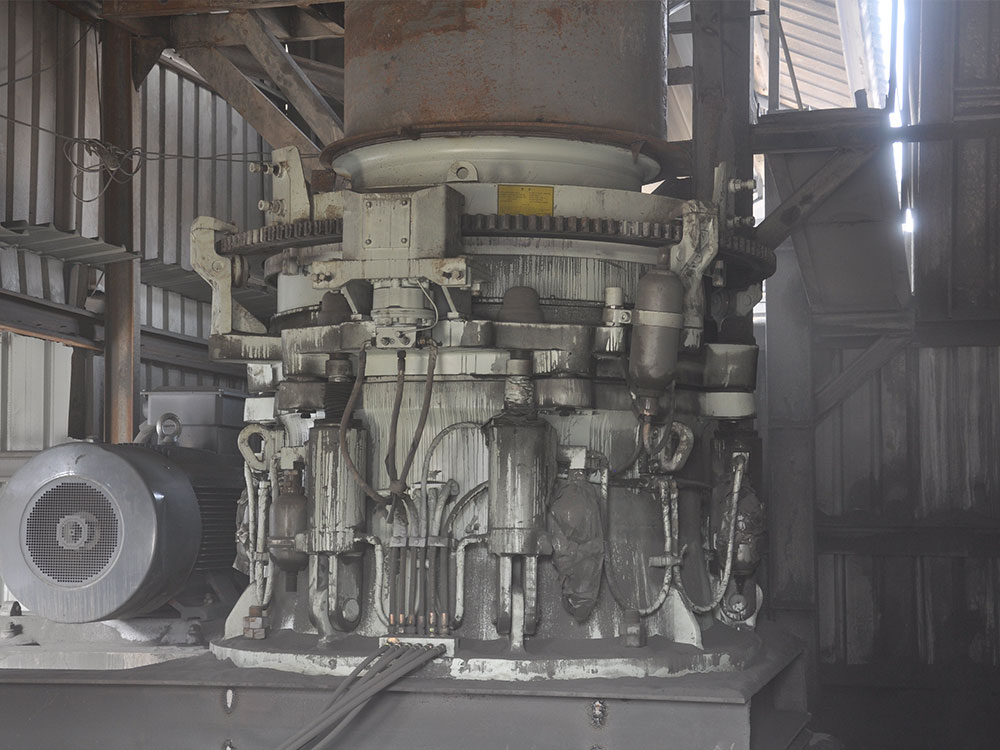

CH860i Cone Crusher adopts advanced crushing technology and design concepts, which can achieve high efficiency and stable crushing operation. The equipment is equipped with a hydraulic adjustment system, which can easily adjust the size of the discharge opening and the size of the product particle size to meet different production requirements. The structure of the equipment is reasonably designed and easy to maintain and service, reducing downtime and maintenance costs.CH860i Cone Crusher is widely used in mining, metallurgy, construction, chemical industry and other industries. It is especially suitable for crushing operations of medium-hard materials, such as iron ore, copper ore, limestone and so on. In these industries, CH860i Cone Crusher has won wide praise from users for its high efficiency, stability and reliable performance.CH860i Cone Crusher has high popularity and reputation in the market. Users have highly praised its performance, stability and durability. At the same time, the equipment also has better after-sales service and technical support, providing users with a full range of service guarantee.

CH860i crusher cone design is more powerful Applications

In mining operation, CH860i Cone Crusher can easily crush ores with large particle size, providing convenience for subsequent ore processing and refining. Its unique crushing chamber design and optimised crushing mechanism enable the ore to be uniformly crushed and ground during the crushing process, thus achieving highly efficient crushing results. At the same time, the machine has excellent stability and durability, and is able to operate stably for a long time in harsh mining environments, greatly reducing maintenance costs and downtime. In the metallurgical industry, the CH860i cone crusher also plays an important role in processing various metallurgical raw materials, such as limestone and dolomite. These raw materials need to be crushed during the smelting process to achieve the appropriate particle size for subsequent batching and smelting. the CH860i Cone Crusher ensures that the raw materials meet the smelting requirements by virtue of its precise crushing control and high crushing efficiency, thus improving smelting efficiency and product quality. In the construction industry, CH860i cone crusher is also one of the key equipment for producing sand and gravel aggregate. With the rapid development of the construction industry, the demand for sand and gravel aggregate is increasing. CH860i Cone Crusher is able to crush all kinds of rocks and ores, and produce sand and gravel aggregate that meets the requirements of the construction, which provides strong support for the construction industry. Its efficient crushing capacity and flexible production capacity enable the construction industry to easily cope with various complex engineering requirements. In the chemical industry, the CH860i Cone Crusher also has a wide range of applications. It can be used to crush a variety of chemical raw materials, such as quartzite and granite. These raw materials need to be crushed during the chemical production process in order to reach the appropriate particle size requirement for subsequent processing and reaction. the CH860i Cone Crusher provides a reliable solution for raw material processing in the chemical industry with its excellent crushing effect and stable performance.

CH860i crusher cone design is more powerful Advantages

Highly efficient crushing capacity

The CH860i Cone Crusher has a powerful crushing capacity, capable of handling materials of various hardnesses and particle sizes. Its well-designed crushing chamber and advanced crushing technology ensure efficient and stable crushing of materials in the crushing process, thus improving production efficiency.

Flexible adjustment

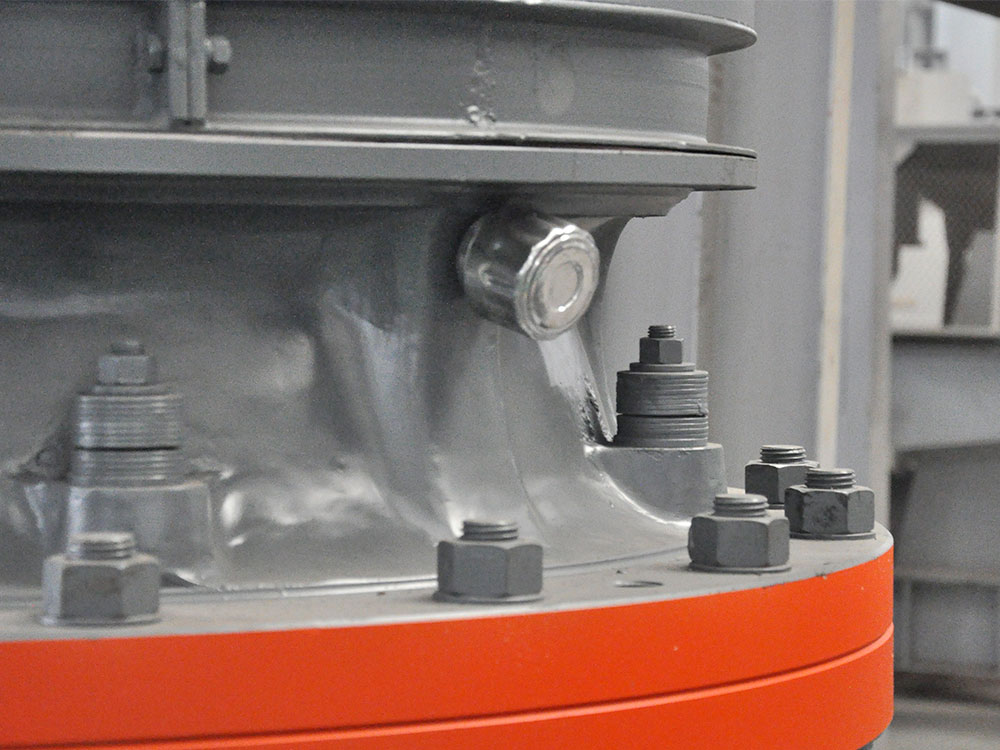

The machine is equipped with a hydraulic adjustment system, which makes it easy to adjust the size of the discharge opening and the size of the product particle size. This feature enables the CH860i Cone Crusher to easily cope with different production demands, providing users with greater operational flexibility.

Stable operation

The CH860i Cone Crusher is made of high-quality materials and advanced manufacturing technology to ensure the stability and durability of the equipment. During long-term use, the equipment can maintain stable performance, reduce the failure rate and lower maintenance costs.

Easy maintenance

The structure of the equipment is reasonably designed and easy to maintain and repair. Users only need to follow the operation manual to carry out routine maintenance and repair to ensure the long-term stable operation of the equipment. At the same time, the replacement of wearing parts of the equipment is also convenient and quick, reducing downtime and maintenance costs.

Energy saving and environmental protection

The CH860i Cone Crusher is designed and manufactured with energy saving and environmental protection in mind. The equipment adopts advanced crushing technology and design concepts, which reduces energy consumption and noise pollution, and at the same time reduces dust emission, in line with the requirements of modern industry for environmental protection.

CH860i crusher cone design is more powerful Working Principle

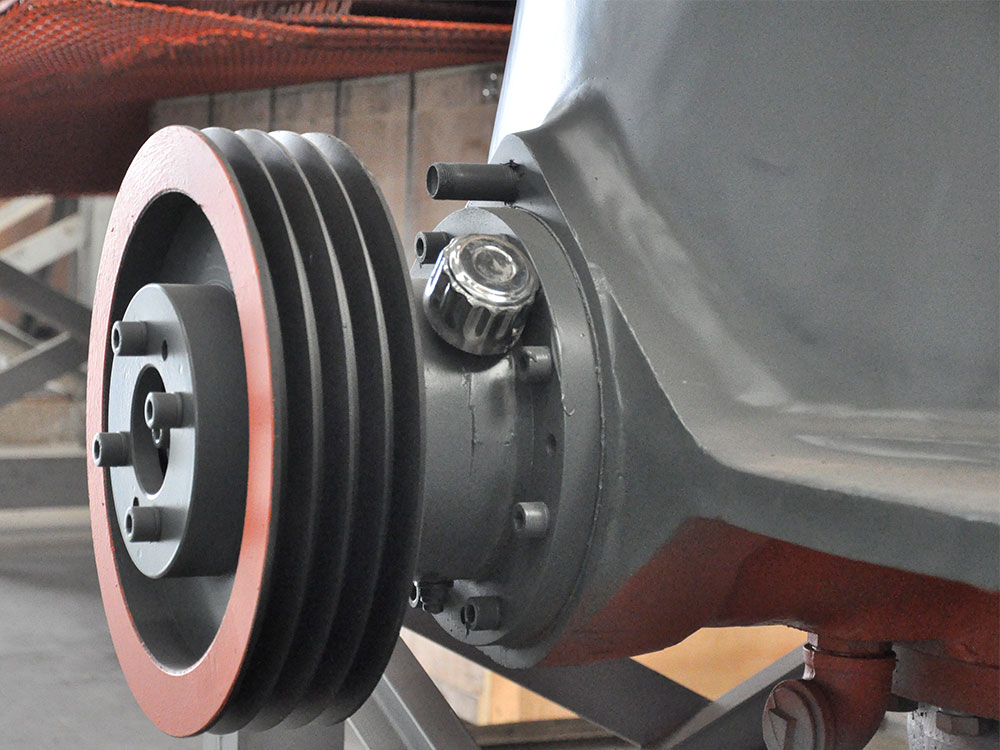

When the CH860i Cone Crusher is working, the rotation of the electric motor plays a key role. The electric motor, through the pulley or coupling shaft, and the transmission shaft of the cone crusher, drives the cone part to make a rotary oscillation movement around a fixed point of a week under the compulsion of the eccentric sleeve. This rotary motion makes the crushing wall of the crushing cone sometimes close to, and sometimes away from, the surface of the molar wall fixed on the adjusting sleeve.

When the crushing wall is close to the wall, the material is sandwiched between the two, by the strong impact and extrusion. As the crushing wall continues to swing, the material is continuously impacted, squeezed and bent in the ring-shaped crushing chamber composed of the fixed cone and the moving cone, and finally crushed. After many times of extrusion, impact and bending, the material is crushed to the required size and discharged from the lower part of the crusher.

This process not only achieves material crushing, but also ensures uniform particle size and stable quality of the crushed material. CH860i Cone Crusher plays an important role in many industrial fields by virtue of its high efficiency and stable working principle.

CH860i crusher cone design is more powerful Technical Parameters

| feed size | 315 mm | power | 500 kW |

| Closed side setting range | 13 - 51 mm | Eccentric throw range | 30 - 70 mm |

| capacity | 250 - 900 tph | Weight | 39,710 kg |