CH895i Cone Crusher Innovative Design Intelligent Crushing

The CH895i cone crusher, with its enhanced crushing power, further reduces material size, produces finer grains and effectively reduces cyclic loads in closed circuits. The spindle strength has been increased by 65% and the upper and lower frame bodies have been strengthened and cast optimised by 50% to ensure top reliability and availability. The bolt-on arm and liner design reduces maintenance time by up to 90% compared to welding, making the process quicker and safer. The built-in automation system optimises crusher performance to avoid overloading and automatically adjusts settings to compensate for chamber wear to ensure uniform product size.The CH895i is designed for tertiary, quaternary and recalcitrant crushing applications, and is able to cope with a wide range of hardnesses and sizes with ease. The CH895i is designed for tertiary, quaternary and recalcitrant applications and can easily handle a wide range of hardnesses and sizes. With a flexible selection of chamber types and eccentric pitches, the crusher can be easily adapted to meet the changing production conditions.

CH895i Cone Crusher Innovative Design Intelligent Crushing Applications

In the chemical industry, the CH895i Cone Crusher is capable of crushing a wide range of raw materials to meet the stringent requirements of chemical production. In the building materials industry, the CH895i can easily crush both river pebbles and granite, providing a solid backing for the production of high-quality building materials. In the metallurgical industry, the CH895i is capable of crushing metal ores and slag, providing stable and efficient crushing service for metallurgical production. In large quarries, the CH895i Cone Crusher efficiently crushes rocks and gravel, providing high-quality aggregates for the construction of buildings, roads, bridges and other infrastructures. Designed for mining crushing applications, CH895i has become an irreplaceable key equipment in the mining industry with its powerful crushing force and adjustable crushing chamber.

CH895i Cone Crusher Innovative Design Intelligent Crushing Advantages

The CH895i Cone Crusher, with its advanced technical design, demonstrates powerful crushing force and can easily cope with all kinds of hardness and sizes of ores, which significantly improves the production efficiency of mines. Its adjustable crushing chamber and eccentricity provide the perfect solution for different ore crushing needs, ensuring the best crushing results.

The strength of the main shaft has increased by 65%, and the upper and lower frame bodies have been strengthened and optimised by 50%, resulting in the robustness of the CH895i. This not only improves the reliability and durability of the equipment, but also ensures stable operation for a long period of time and significantly reduces downtime, which protects the overall operational efficiency of the mine.

Intelligent management is also a highlight of the CH895i. The advanced automation system monitors and optimises crusher performance in real time, and through the My Sandvik portal, users can keep track of equipment data and make informed decisions. This intelligent management allows mining companies to control the status of their equipment, optimise production plans and maximise efficiency.

The CH895i Cone Crusher stands out for its easy maintenance and serviceability. The bolt-on arm and body liner reduce maintenance time by up to 90% compared to welding, making the process quicker and safer. The one-piece mainframe design not only ensures optimum strength, but also reduces maintenance requirements, lowering operating costs for the mine.

In addition, the CH895i offers a wide range of standard crushing chamber options, such as EEF (Extra Fine), EF (Extra Fine), EFX (Extra Fine), and HR (High Reduction Ratio). This flexible configuration allows the machine to easily cope with the crushing needs of different ores and improve crushing efficiency and product quality.

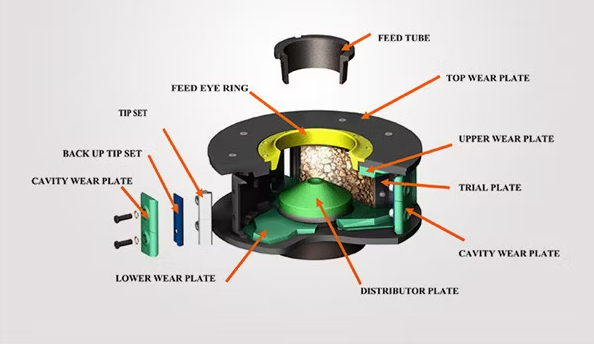

CH895i Cone Crusher Innovative Design Intelligent Crushing Working Principle

As soon as the material is fed into the crusher, the motor starts the drive. This process is transmitted by the horizontal shaft and a pair of bevel gears to drive the eccentric bushing rotation. As the eccentric bushing rotates, the crushing cone axis is driven by it to carry out a rotary motion, making the surface of the crushing wall and the surface of the mortar wall fixed on the adjusting bushing close to each other at times and far away from each other at times.

In the crushing cavity, the material is subjected to the internal and external two closely rotating cone surface continuous extrusion and impact. This series of extrusion and impact, gradually refine the material to the required particle size. Eventually, the crushed materials are discharged smoothly from the lower part of the crusher, and the whole crushing process comes to a successful end.

The CH895i Cone Crusher also incorporates advanced automation systems and regulators. These systems closely monitor the operating status of the crusher and automatically adjust the crusher settings according to actual requirements. For example, in the event of wear and tear in the crushing chamber, the automation system quickly adjusts the crusher parameters to ensure consistent product size.

CH895i Cone Crusher Innovative Design Intelligent Crushing Technical Parameters

| feed size | 127 mm | power | 750 kW |

| Weight | 84,343 kg | Concaves | EFX, EF, EEF |

| Eccentric throw range | 24 - 70 mm | Closed side setting (CSS) range | 10 - 70 mm |