CI712 crusher helps mining, construction, sand and gravel field

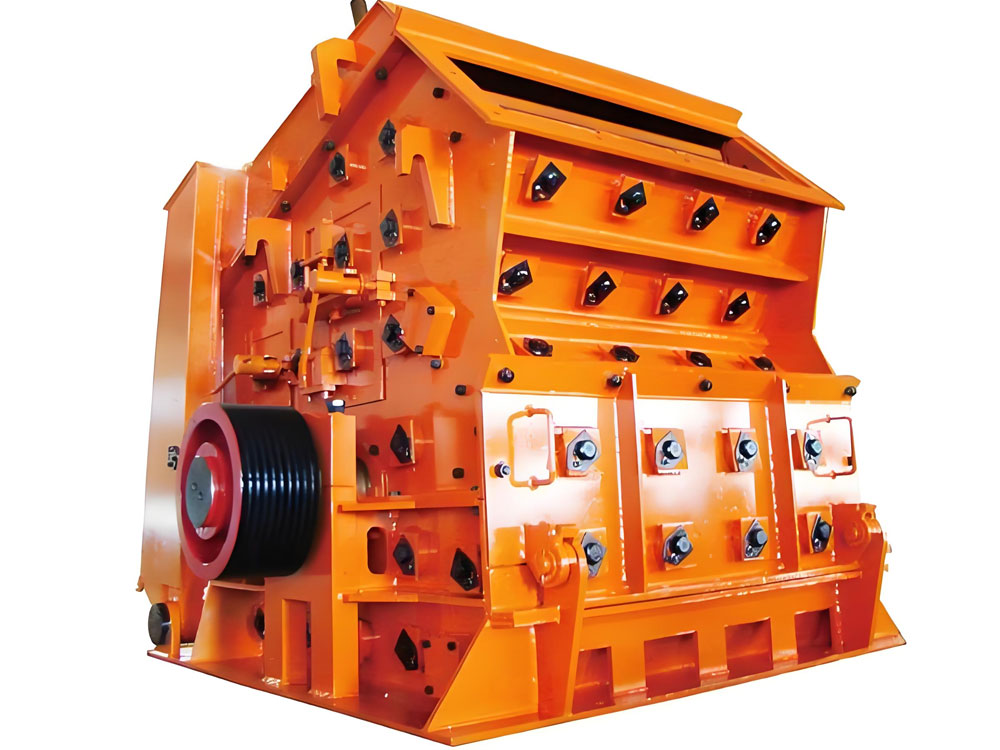

CI712 impact crusher is an efficient and durable crushing equipment, widely used in many fields such as mining, metallurgy, chemical industry, building materials and hydropower. Its excellent design and performance make it an indispensable part of industrial production. The crusher demonstrates its robustness and durability. With a maximum feed size of up to 300 mm (23.6 inches), it is able to meet the crushing needs of medium-hard materials, such as limestone and construction waste. In terms of throughput, the CI712 impact crusher has a capacity of less than 150 tonnes per hour, ensuring efficient and stable crushing operations.

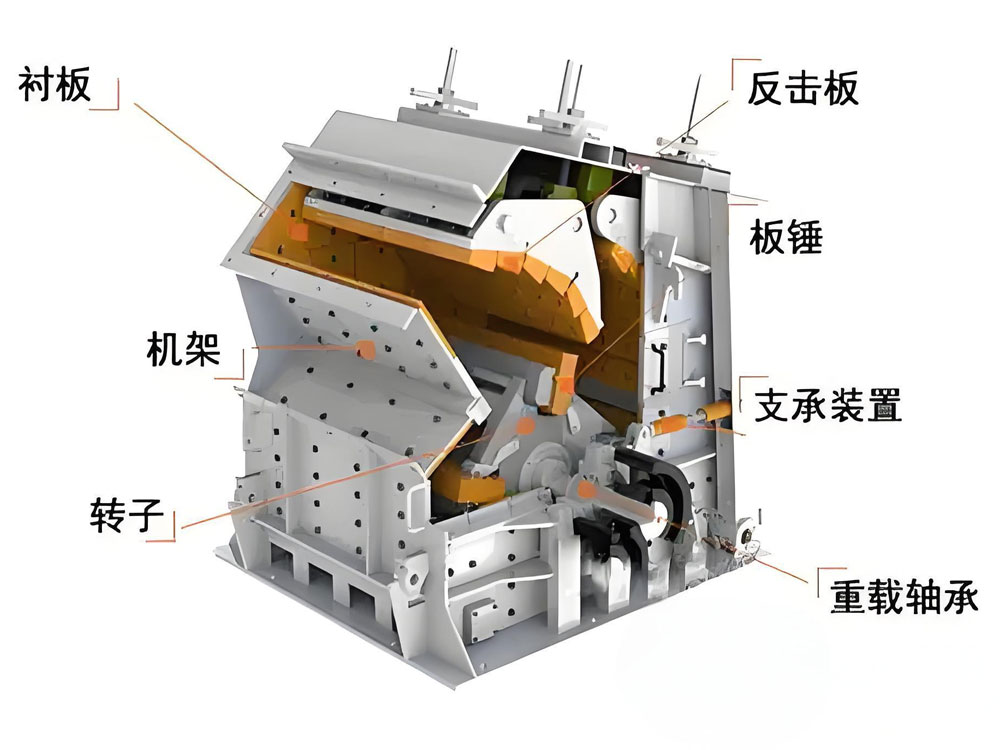

The CI712 impact crusher adopts modular design and supports intelligent configuration, enabling it to flexibly adapt to different application scenarios. Whether it is in primary or secondary crushing mode, the machine performs excellently. In addition, its design complies with the latest EU regulations, ensuring safe and environmentally friendly operation. During the crushing process, the CI712 impact crusher demonstrates a high crushing ratio and excellent material shape. Its unique cavity and rotor design makes the crushed material cubic particles without tension and cracks, which meets the demand for high quality construction aggregates. Meanwhile, the equipment also has adjustable discharge size, which can be adjusted according to the actual needs of users to achieve diversified crushing specifications. In terms of maintenance, the CI712 impact crusher adopts a fully hydraulic system, which makes it easy to replace accessories such as plate hammers, impact blocks, liners, etc., and reduces maintenance costs and time. In addition, its high wear-resistant steel plate and plate hammer are made of high chromium alloy, which significantly reduces the degree of wear and prolongs the service life of the equipment.

CI712 crusher helps mining, construction, sand and gravel field Applications

As an efficient and multi-functional crushing equipment, CI712 impact crusher shows wide application value and excellent performance in many fields.

In the field of mining, CI712 impact crusher plays a vital role. Ore mining is often accompanied by the output of large ores, which need to be crushed to meet the requirements of subsequent ore dressing, smelting, etc. With its powerful crushing capacity and efficient processing performance, CI712 Impact Crusher can easily crush ores into smaller sizes, providing high-quality raw materials for subsequent processes. At the same time, the equipment is also capable of handling some ores containing impurities, which can be effectively separated from the ores through crushing and screening, thus improving the utilisation rate of the ores and reducing the production cost.

In the construction field, CI712 impact crusher also performs well. With the acceleration of urbanisation, the disposal of materials such as construction waste and waste concrete has become an urgent problem. the CI712 impact crusher can crush these waste materials and turn them into recycled aggregates, which can be used for the production of new construction materials, such as recycled concrete, recycled bricks, etc. This not only realises the recycling of resources, but also reduces the cost of production, and reduces the cost of production. This not only realises the recycling of resources, but also helps to reduce the pollution of construction waste to the environment, which is in line with the modern green and environmental protection development concept.

In the field of infrastructure construction such as highway and railway, CI712 impact crusher also plays an irreplaceable role. Stone is one of the important raw materials for infrastructure construction, and the crushing of large stone is the key link in stone processing, CI712 impact crusher can crush large stone into the required size, providing high quality crushed stone materials for roadbed filling and paving processes. At the same time, this equipment also has the characteristics of high efficiency and energy saving, which can reduce the production cost and improve the construction efficiency.

In addition, CI712 impact crusher is also widely used in the cement industry. Cement production requires a large number of raw materials, such as limestone, etc. CI712 impact crusher can crush and screen these raw materials to meet the requirements of cement production on the particle size of raw materials. At the same time, this equipment can also deal with some raw materials containing impurities, improve the purity and utilisation of raw materials, so as to ensure the quality and production efficiency of cement.

CI712 crusher helps mining, construction, sand and gravel field Advantages

High-efficiency crushing capacity

CI712 impact crusher has powerful crushing force, especially suitable for crushing operation of medium hardness materials, such as limestone. Its unique design enables large crushing ratio and high crushing efficiency, which can easily cope with the demands of large-scale production. In practical application, the equipment can quickly crush materials to the required size, providing high-quality raw materials for subsequent processes, thus effectively improving the overall efficiency of the production line.

Excellent product size

In order to ensure the uniformity of the crushed materials, the CI712 Impact Crusher adopts an adjustable gap design between the impact plate and the hammer. By precisely adjusting the gap, users can flexibly control the particle size of the discharged material to meet the needs of different application scenarios. The crushed material is in the form of cubic granules without tension or cracks, which not only has a beautiful appearance, but also has excellent quality, which is fully in line with the production standard of high-quality construction aggregates.

Energy saving and low consumption

Under the current production concept of advocating green and environmental protection, CI712 Impact Crusher excels in energy saving. It adopts advanced energy-saving design, lower energy consumption and more economical operation cost compared with other similar crushing equipment. In addition, the equipment is equipped with wear-resistant parts such as high chrome plate hammers, which not only have excellent wear-resistant performance, but also have a long service life, further reducing the maintenance cost of the equipment.

Compact structure, easy maintenance

The CI712 impact crusher has been designed with the user's convenience in mind. Its compact structure and small footprint not only save production space, but also facilitate production management. At the same time, the equipment adopts a modular design, the connection between the components is tight and easy to disassemble and replace. This design greatly reduces the difficulty and time of maintenance, so that the user in the maintenance of the equipment more effort.

Strong adaptability

The CI712 impact crusher has won the favour of the majority of users with its strong adaptability. It can handle materials of different hardness and particle size, whether it is hard ore or loose construction waste. Therefore, this equipment is widely used in many fields such as mining, construction, highway, railway and so on, which meets the needs of different industries for crushing equipment.

Safe and Reliable

Safety is an important factor that cannot be ignored in production equipment, and CI712 Impact Crusher has done a very good job in terms of safety. The equipment is equipped with a variety of safety locking devices, which can effectively prevent accidents from occurring at critical moments, thus improving the safety of operation. At the same time, the design of the equipment complies with the latest safety standards, which ensures the safety of the operators in the production process without any worry.

CI712 crusher helps mining, construction, sand and gravel field Working Principle

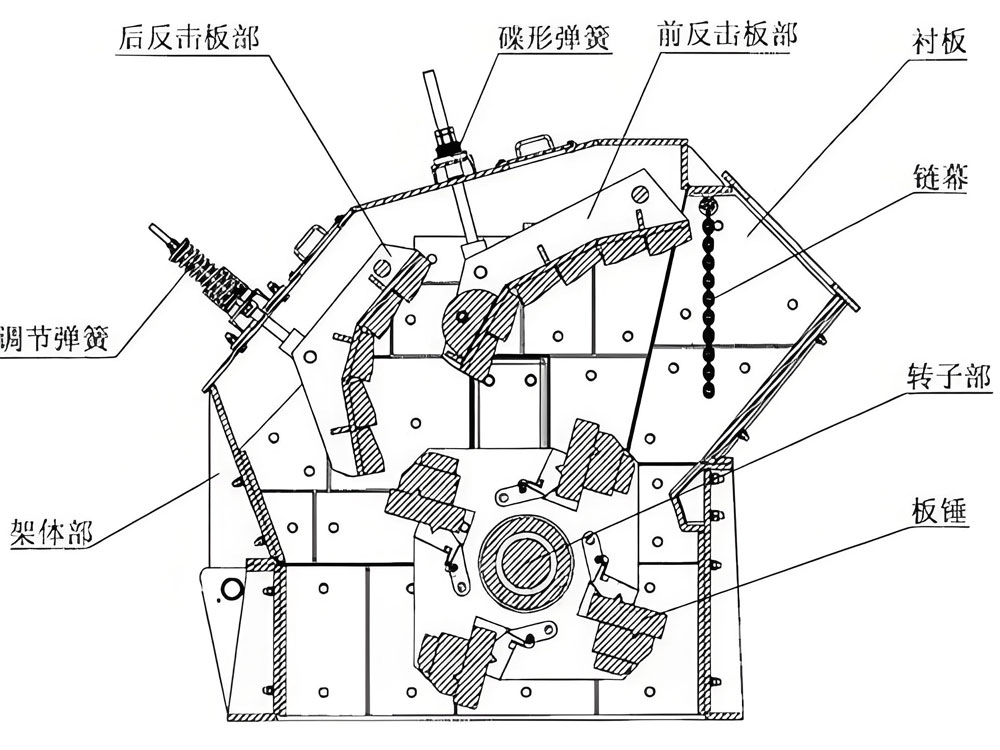

The working principle of the CI712 impact crusher is subtle and efficient, centred on the interaction between the material and the tools. This interaction not only ensures thorough crushing, but also gives the machine a number of advantageous features that make it the preferred choice for many crushing operations. When the material falls into the crushing chamber of the CI712 Impact Crusher from the feeder, a well-designed crushing journey begins. Firstly, the material will hit the plate hammers on the high-speed rotor head-on. These hammers are specially designed to be not only hard and wear-resistant, but also have a very high rotational speed, which can produce a strong impact on the material. Under the action of this impact, the material is quickly broken into smaller particles.

The material will not stop moving immediately after the initial impact, but will be thrown to the impact plate on the other side of the crushing chamber at a high speed along the tangential direction of the hammer rotation. The impact plate is also made of wear-resistant material, and its position, angle and hardness are all precisely calculated to ensure the best impact effect with the material. After impacting the impact plate, the material will bounce back and impact with the hammer or other materials again. This repeated impact and collision process is like a fierce ‘crushing feast’, so that the material is constantly crushed into smaller particles.

It is worth mentioning that, in the process of the materials going back and forth between the plate hammer and the impact plate, there is a mutual impact between the materials. This mutual collision between the materials not only further promotes the crushing effect, but also makes the crushed material size more uniform. This ‘fratricidal’ crushing method not only improves the crushing efficiency, but also reduces energy consumption and noise.

In order to achieve precise control of the crushing size, CI712 Impact Crusher is also cleverly designed with the function of adjusting the gap between the impact plate and the hammer. Users can adjust this gap to change the material discharge size according to the actual demand. When the granularity of the material is smaller than the gap between the impact plate and the hammer, the material will be smoothly discharged from the crusher and become the crushed product. This design not only makes the crushing process more flexible and controllable, but also meets the diversified needs of different users for crushing granularity.

CI712 crusher helps mining, construction, sand and gravel field Technical Parameters

| Max. feed size | 300 mm | Weight | 11,184 kg |

| Power | 185 kW | Length | 2.84 m |

| Width | 2.00 m | Height | 2.29 m |