CI722 Precision Aggregate Size Control

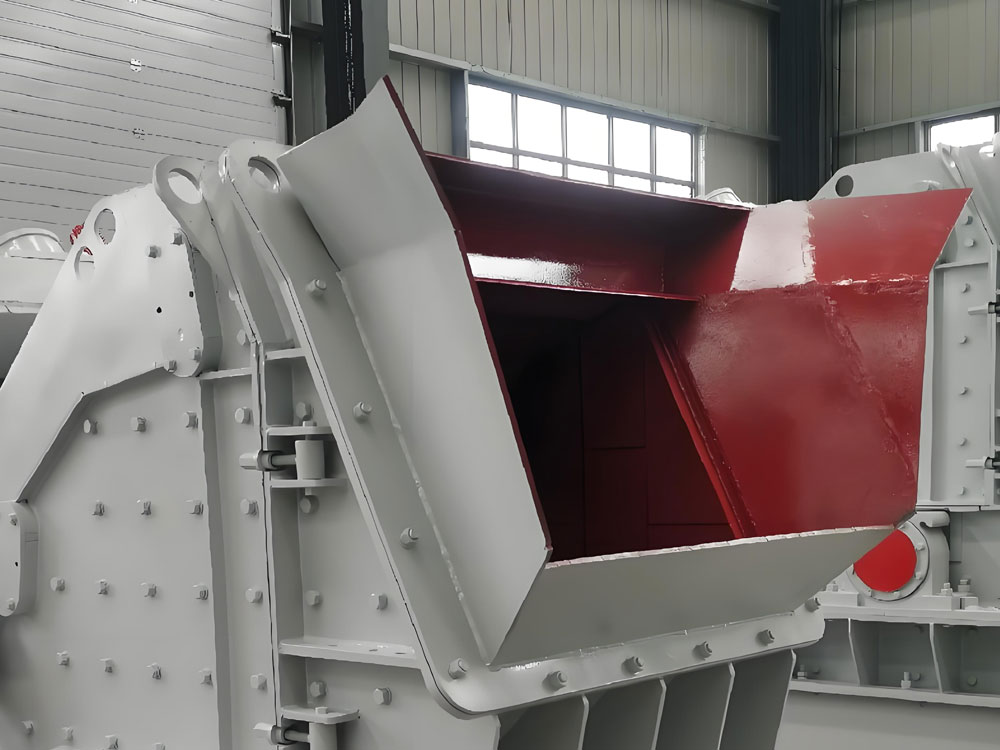

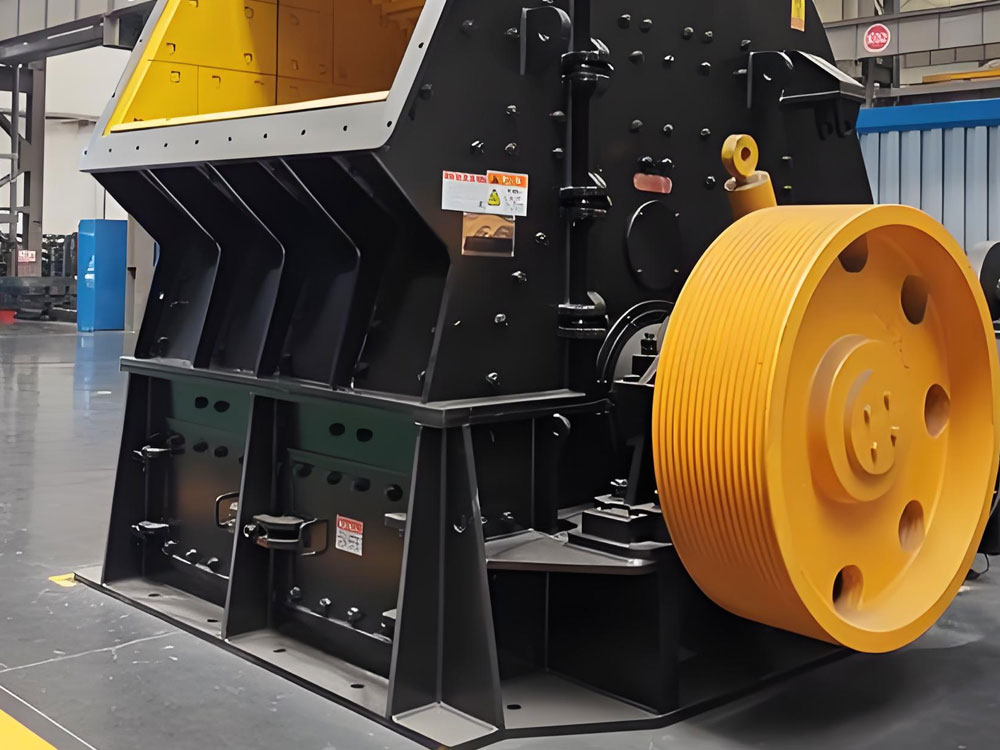

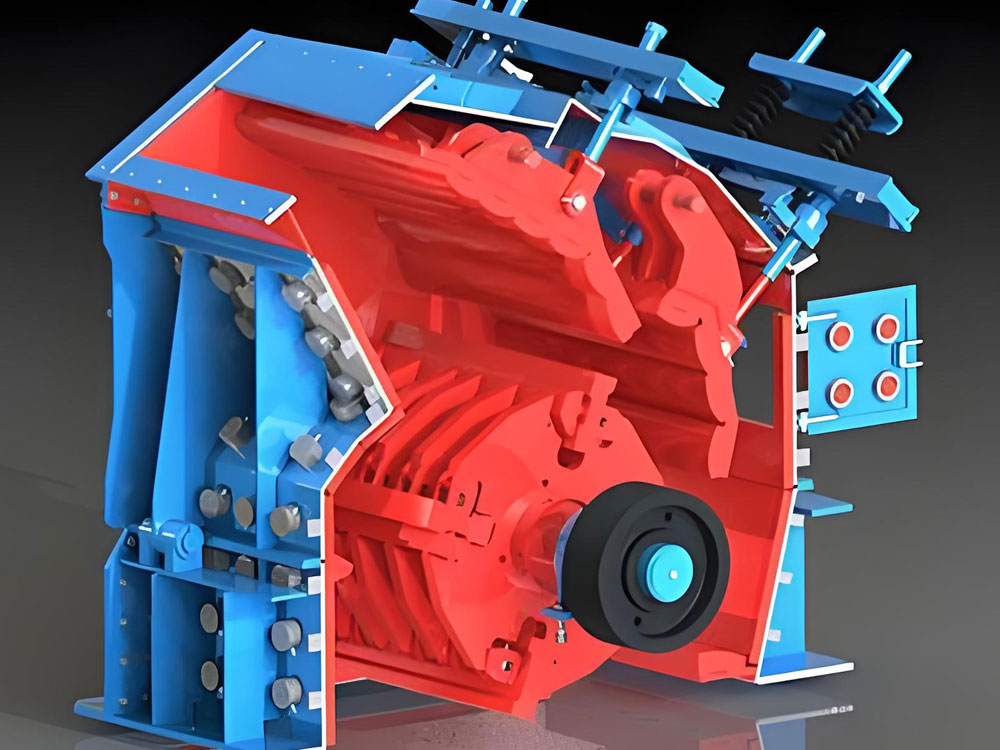

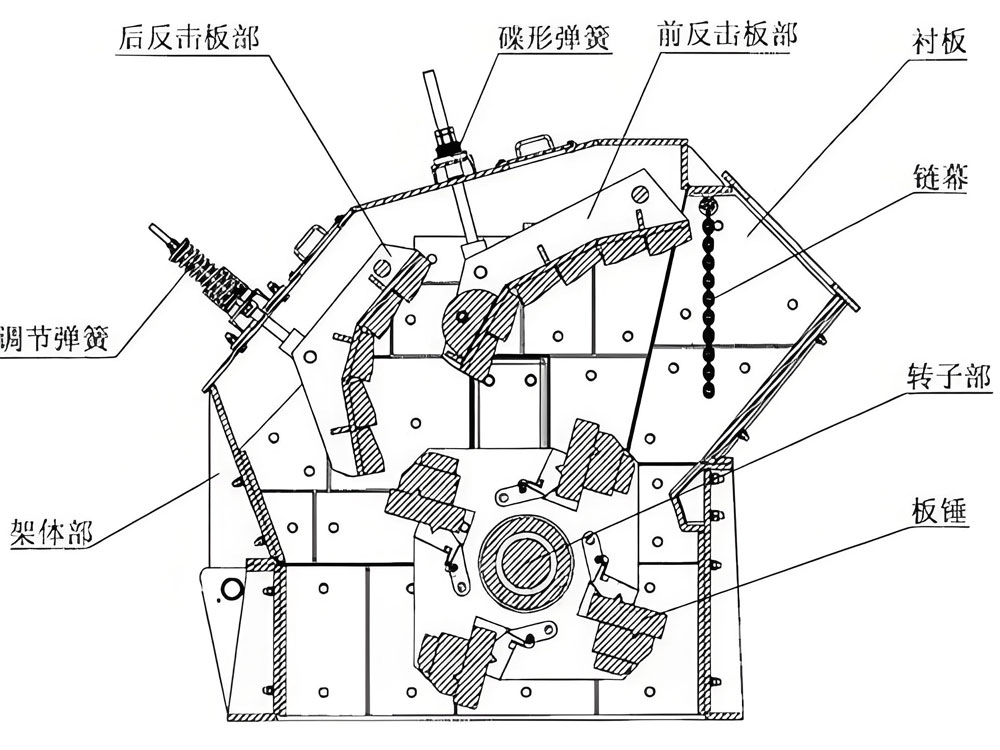

CI722 Impact Crusher is a kind of high-efficient medium and large-sized crushing equipment, which adopts the principle of impact energy to crush materials, and is suitable for processing all kinds of medium and hard ores and construction wastes with the compressive strength ≤350MPa and the particle size ≤500mm, etc. Its core structure includes rotor, plate hammer, impact plate and other components. Its core structure includes rotor, plate hammer, impact plate and other components, when working, the motor-driven rotor rotates at high speed, the material is impacted by the plate hammer and the impact plate repeatedly collide with the crushing, and finally form cubic particles, the discharge size can be flexibly controlled by adjusting the gap between the impact plate. This equipment has the advantages of single/double rotor design (the specific configuration should be based on the actual model parameters), with high crushing ratio, low energy consumption, easy maintenance and other characteristics, especially suitable for crushing limestone, granite, concrete and other materials. In the production line, it is often used as secondary crushing equipment, with the jaw crusher, the processing capacity of up to 250 tonnes / hour, widely used in mining, building materials, hydropower engineering and construction waste resources CI722 adopts high chromium alloy hammer and hydraulic adjustment system, wear resistance and convenient operation, support remote control to adjust the discharge specification, effectively reduce maintenance costs and improve production efficiency. It effectively reduces maintenance cost and improves production efficiency. Its compact structure and keyless connection design further guarantee the stability and economy of the equipment.

CI722 Precision Aggregate Size Control Applications

For non-abrasive rocks, such as limestone and granite, which are suitable for processing with specific secondary crushing plants due to their physical characteristics. These plants can easily cope with medium-hard ores with a compressive strength of up to 350 MPa, and through a precise crushing mechanism, produce cubic aggregates with a grain size range of 0-70 mm. These aggregates are not only of uniform specification but also of high quality, which are perfectly suited for the subsequent processes of mineral processing and smelting, providing a solid foundation for the production of related industries.

In the process of urbanisation, the disposal of construction waste has become an urgent problem. Through advanced crushing technology, we can convert construction waste such as reinforced concrete and waste concrete into valuable recycled aggregates. After these recycled aggregates are screened, cleaned and other processes, the quality can be comparable to natural aggregates, which are widely used in the production of new building materials. This initiative not only solves the environmental problems caused by the accumulation of construction waste, but also realises the recycling of resources and promotes the development of green building materials.

In the construction of roads, railways and other transport infrastructure, the requirements for aggregate particle size are extremely strict. In order to meet these demands, crushing equipment is widely used to process roadbed filler and flowable stone. By adjusting the crushing parameters, aggregates can be accurately produced to meet specifications, such as Class 1 aggregates (0-40 mm) or railway ballast (40-70 mm). These aggregates provide the stability and durability of transport infrastructure.

Crushing of cement raw materials and sand and gravel aggregates is also one of the important application areas of crushing plants. After crushing, the particle size of limestone, slag and other raw materials is precisely controlled, which meets the strict requirements of building materials production line on material particle size. This not only improves the production efficiency, but also ensures the quality and stability of building materials products.

The crushing plant also excels in handling medium-hard, non-abrasive materials. After crushing, these materials become the basic raw materials for water conservancy projects, chemical fillers and other fields. Their wide application further broadens the application scope of crushing equipment and provides strong support for the development of related industries.

CI722 Precision Aggregate Size Control Advantages

Highly efficient crushing capacity

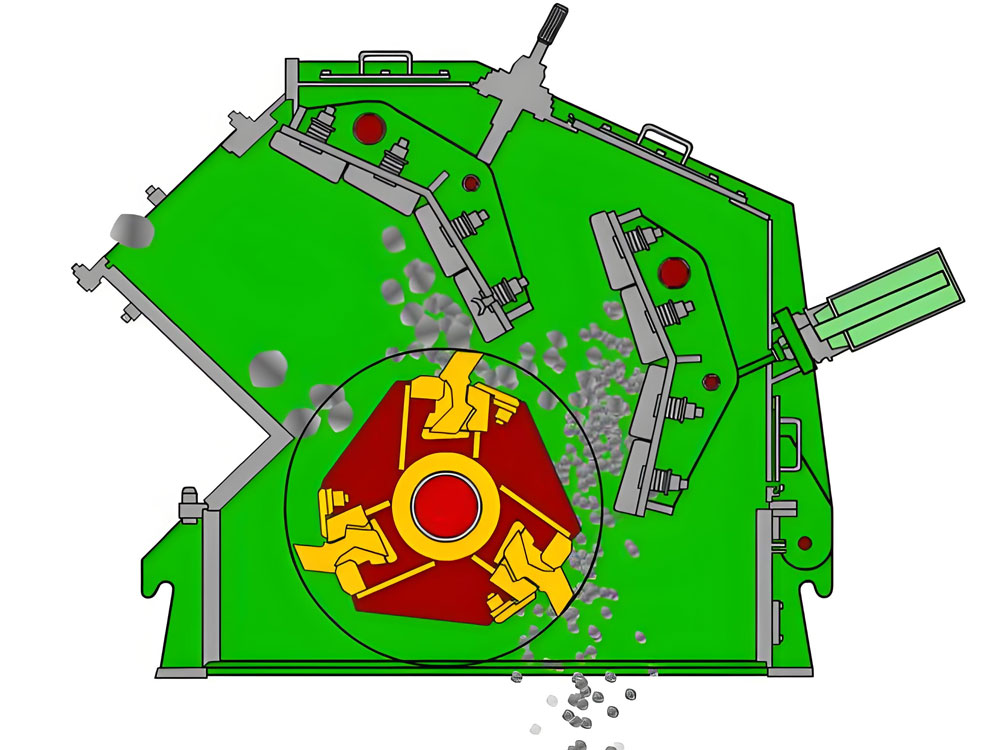

The machine stands out with its excellent crushing capacity. With a maximum feed size of 350mm and a capacity of 150-250 tonnes/hour, it easily meets the needs of medium and large-scale crushing operations. In order to achieve high crushing efficiency, the machine adopts a high-speed rotor, whose speed can be adjusted according to the actual demand. At the same time, the high chrome alloy hammer is equipped with powerful impact energy to achieve accurate crushing of materials, and the output particles are mostly cubic in shape, which greatly reduces the proportion of needle and flake materials. In addition, the equipment also combines the impact crushing principle with the natural knuckle surface cracking technology, with a crushing ratio as high as 20:1, and the unit energy consumption is reduced by about 15% compared with the traditional equipment. It is worth mentioning that its open rotor design effectively avoids material clogging, thus enhancing the stability of continuous operation.

Flexible adjustment and precise control

It supports hydraulic adjustment of the gap of the impact plate, so that the particle size of the discharged material can be quickly switched, such as 0-40mm or 40-70mm and other specifications, which is perfectly adapted to the needs of different aggregate specifications. At the same time, the equipment is also equipped with overload protection function, when encountered with foreign objects jammed and other emergencies, can quickly start the protection mechanism to avoid equipment damage. In addition, the equipment can also be equipped with remote control system, users can understand the operating status of the equipment through remote monitoring in real time, and adjust the parameters according to the actual needs, without the need for on-site operation, which greatly improves the work efficiency.

Durability and maintenance convenience

It adopts a keyless connecting rotor and high chrome alloy plate hammer, the hardness of which is up to HRC60 or more, and the abrasion resistance has been increased by 50%, thus greatly extending the service life. At the same time, the design of the grinding bar at the bottom supports quick replacement, greatly reducing downtime. The open casing design makes the replacement of plate hammers easier and faster, which can be completed in only one shift, reducing the complexity of maintenance. In addition, the hydraulic assisted opening device further simplifies the maintenance process and improves operational safety.

Multi-scenario adaptability

It is suitable for medium-hard materials with compressive strength not exceeding 350MPa, such as limestone, granite, etc. It can also be used for the recycling of construction waste, such as reinforced concrete and asphalt concrete. The special heating device is equipped so that this equipment can handle high humidity materials, effectively avoiding the problem of caking and clogging. As a secondary crushing equipment, it works well with jaw breakers and other equipment to form a complete production line, which is perfectly suited to the needs of mining, building materials, construction waste recycling and other industries.

Outstanding economic benefits

The long life and low maintenance cost of its wear parts, combined with its high processing capacity, reduces the cost of crushing per tonne by about 20%. At the same time, this equipment reduces the dependence on screening and conveying equipment, shortens the production line configuration cycle, and thus brings more considerable economic benefits for users.

CI722 Precision Aggregate Size Control Working Principle

After entering the crushing chamber from the feeding port, the material is firstly hit by the high-speed rotor (equipped with high hardness hammers), and then crushed into coarse particles and thrown to the counterattack plate, and then collided with the counterattack plate, and then collided with the subsequent materials or hammers again. After colliding with the impact plate, the projected materials will rebound back to the rotor area and collide with the subsequent materials or hammers again, forming repeated impacts and realising multi-stage crushing. The gap between the impact plate and the rotor can be adjusted by the hydraulic system: the smaller the gap is, the more impacts the materials will receive, and the finer the granularity of the discharged materials will be (e.g. 0-40mm); the larger the gap is, the finer the discharged materials will be. The smaller the gap, the more impacts the material receives, the finer the granularity (e.g. 0-40mm); when the gap is increased, the number of material crushing is reduced, and the granularity of the discharged material becomes thicker (e.g. 40-70mm). The surface of the impact plate is designed as folded or curved, which enhances the collision angle of the material and improves the crushing efficiency.) The hard part continues to be crushed in the cycle, eventually forming uniform cubic particles, reducing the proportion of needle-flake materials, materials that reach the target size are discharged from the bottom discharge port, and particles that do not meet the standard continue to stay in the crushing chamber to be crushed in the cycle.

CI722 Precision Aggregate Size Control Technical Parameters

| Max. feed size | 350 mm | power | 250 kW |

| Length | 3.12 m | Width | 2.37 m |

| Height | 2.51 m | Weight | 16,256 kg |