CJ211 jaw crusher is an excellent choice for fixed installation

CJ211 jaw crusher has the characteristics of simple structure, convenient operation and easy maintenance. Its crushing chamber is reasonably designed and has a large crushing ratio, which can efficiently crush the material to the required particle size. At the same time, the equipment adopts high-quality materials and advanced manufacturing technology to ensure the stability and durability of the equipment. The working principle of CJ211 jaw crusher mainly relies on the extrusion between the movable jaw and the fixed jaw. When the movable jaw reciprocates under the drive of the driving mechanism, the material is clamped between the movable jaw and the fixed jaw, and is subjected to strong extrusion and shearing, thereby achieving crushing. The crushed material is discharged from the discharge port of the crusher, completing the entire crushing process. The maintenance of CJ211 jaw crusher is essential to extend the service life of the equipment and improve production efficiency. After long-term continuous operation, the wear of the equipment should be checked in time, and it should be maintained and replaced. Check the condition of the lubricating oil regularly, clean and replace the detached oil stains. At the same time, it is also necessary to regularly check whether the fasteners of the equipment are loose and tighten them in time. In addition, regular inspection and maintenance of conveyors, belts, etc. are also important measures to ensure the normal operation of the equipment.

CJ211 jaw crusher is an excellent choice for fixed installation Applications

In mining, the CJ211 jaw crusher is used to perform preliminary crushing of ore to provide suitable material size for subsequent processing. Its powerful crushing capacity and stable operating performance make ore processing more efficient.

Various raw materials need to be processed in the metallurgical process, and the CJ211 jaw crusher can effectively pre-process them to ensure the smooth progress of the smelting process. Its wide range of applications and large crushing ratio make it play an important role in the metallurgical industry.

In the construction industry, especially in the construction of infrastructure such as roads and bridges, a large amount of crushed stone is required as aggregate material. The CJ211 jaw crusher can operate finely and provide high-quality crushed stone materials for these projects. At the same time, it also shows advantages in the treatment of construction waste, and can effectively crush construction waste into reusable aggregates.

In the recycling of urban garbage and industrial waste, the CJ211 jaw crusher also plays an important role. It can reduce the volume of waste, improve the efficiency and quality of subsequent processing, and contribute to the recycling of resources.

CJ211 jaw crusher is an excellent choice for fixed installation Advantages

CJ211 jaw crusher adopts advanced crushing technology and optimized structural design to ensure efficient crushing capacity. Its deep and symmetrical crushing chamber design allows the material to fall smoothly and be fully crushed, thus improving the crushing efficiency. At the same time, the equipment also has a large crushing ratio, which can quickly crush large pieces of material into the required small pieces, providing convenience for subsequent processing and significantly improving production capacity.

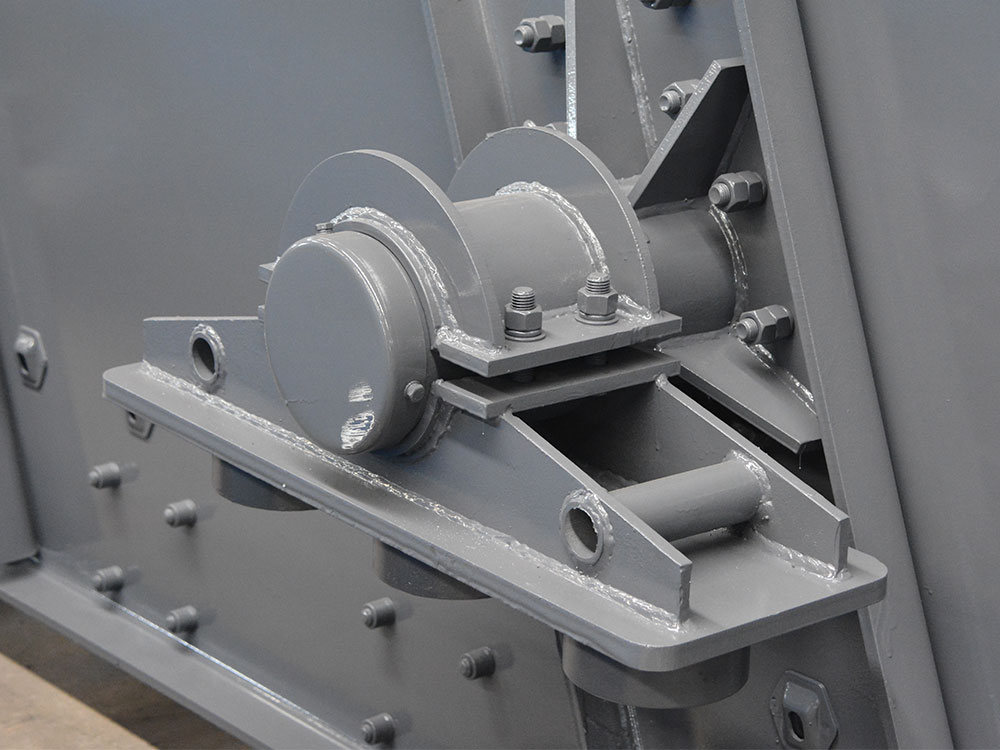

CJ211 jaw crusher has a compact overall structure, occupies a small area and is easy to install and debug. This design enables the equipment to adapt to a variety of complex on-site environments, whether it is a narrow mine tunnel or a spacious factory workshop, it can easily cope with it. In addition, its compact structure reduces the transportation cost of the equipment and provides convenience for users' remote use.

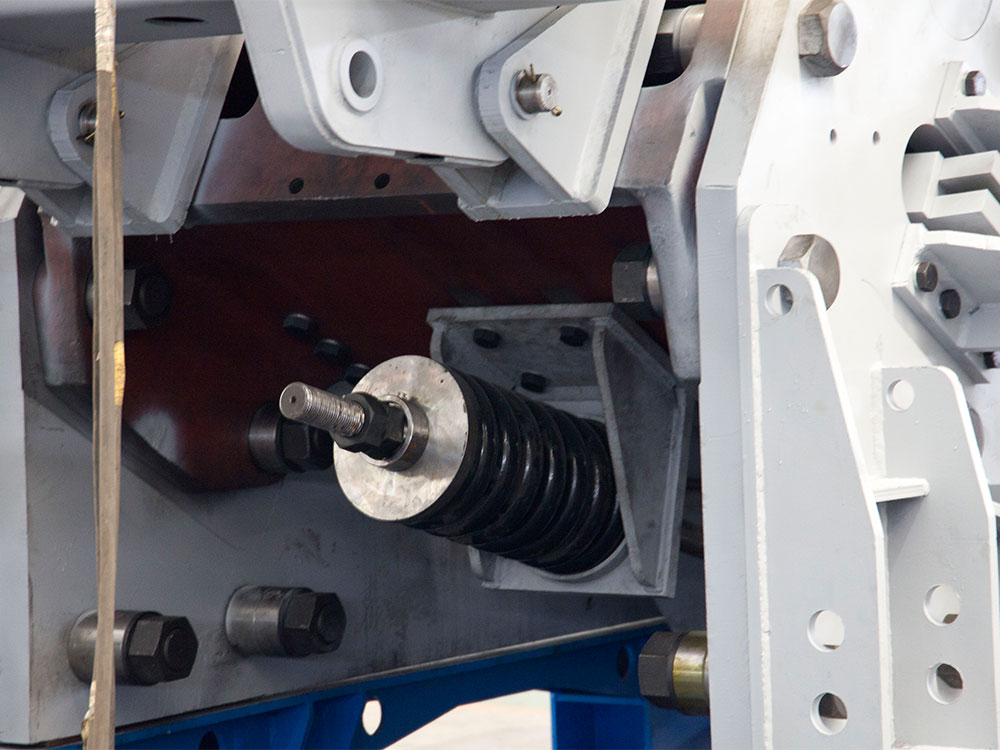

The equipment adopts advanced manufacturing technology and high-quality materials to ensure the stability and reliability of its operation. During operation, CJ211 jaw crusher can maintain stable vibration and noise levels, providing a good working environment for operators. At the same time, the equipment is also quite easy to maintain. Its wearing parts are made of wear-resistant materials, with a long service life, which reduces maintenance costs. In addition, the equipment is equipped with a complete lubrication system and cooling system to ensure the long-term and stable operation of the equipment.

CJ211 jaw crusher is equipped with an advanced intelligent control system, making the operation of the equipment more convenient and efficient. Users can monitor and adjust the operating parameters of the equipment in real time through the control system to ensure that the equipment is always in the best working condition. At the same time, the equipment also has automatic protection and alarm functions. When the equipment fails or an abnormal situation occurs, it can be discovered in time and measures can be taken to deal with it, avoiding production losses caused by equipment failure.

In terms of energy saving and environmental protection, CJ211 jaw crusher also performs well. The crushing technology and structural design adopted by the equipment make the energy consumption lower during the crushing process, reducing energy waste. At the same time, the equipment is also equipped with effective dust removal devices and noise control measures to reduce the impact on the environment. These measures not only meet the country's environmental protection requirements, but also reduce production costs for users.

CJ211 jaw crusher is an excellent choice for fixed installation Working Principle

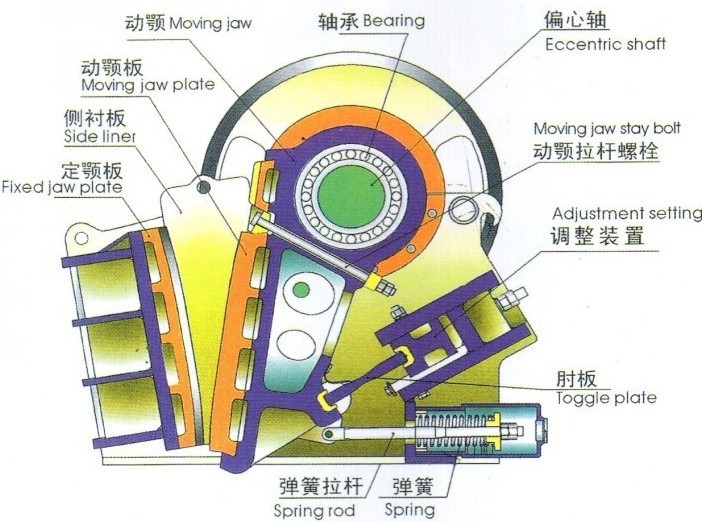

The working principle of the CJ211 jaw crusher is an efficient and orderly process, which starts with the drive of the motor. As the power source of the entire system, the motor transfers kinetic energy to the eccentric shaft through the belt and pulley to drive it to rotate. This rotational action is the key to the crushing process because it causes the movable jaw plate connected to the eccentric shaft to start periodic up and down movement.

The movable jaw plate is closely connected to the eccentric shaft through the connecting rod. As the eccentric shaft rotates, the movable jaw plate also moves up and down accordingly. This movement mode causes the relative position between the movable jaw plate and the fixed jaw plate to change continuously, creating conditions for the crushing of materials.

When the movable jaw plate rises, the angle between the toggle plate and the movable jaw gradually increases, pushing the movable jaw plate closer to the fixed jaw plate. At this time, the material is placed between the two jaw plates. As the movable jaw plate approaches, the material is subjected to increasing extrusion and shear forces. The action of these forces causes the material to be crushed. During the crushing process, the pressure of the material is concentrated in a smaller area. This concentrated pressure helps the material to be crushed more easily and quickly.

When the movable jaw plate moves downward, the angle between the toggle plate and the movable jaw plate becomes smaller, and the movable jaw plate gradually leaves the fixed jaw plate under the action of the pull rod and the spring. At this time, the crushed materials are freely discharged through the discharge port at the bottom of the crushing chamber under the action of gravity, completing a cycle from crushing to discharging.

CJ211 jaw crusher is an excellent choice for fixed installation Parameters

| Feed opening | 1,100 x 700 mm | power | 90 kW |

| Weight | 14,300 kg | Length | 2.4 m |

| Width | 2.4 m | Height | 2.2 m |