CJ409 Jaw Crusher Specifications & Technical Data

The CJ409 jaw crusher belongs to the category of single elbow plate design, combining advanced functions and excellent performance. Its crushing chamber design is deep and symmetrical, which effectively ensures the smooth fall of materials and greatly improves the crushing efficiency. The crusher is equipped with a spacious feed port size of 895x660 mm, which can easily cope with the processing needs of large pieces of materials. In addition, by flexibly adjusting the discharge port, users can achieve crushing effects of different particle sizes to meet diverse production needs. In terms of performance parameters, the CJ409 jaw crusher also performs outstandingly. Its motor power is as high as 75 kilowatts, the weight of the whole machine reaches 14,100 kilograms, and the overall dimensions are 2.55×1.88×2.38 meters. These excellent parameters provide a solid guarantee for the efficient and stable operation of the crusher. At the same time, the crusher also has many advantages such as easy maintenance, long service life and low ton cost, creating considerable economic benefits for users.

CJ409 Jaw Crusher Applications

CJ409 jaw crusher is mainly used in the fields of mining and stone processing. In mines, it is often used to crush ores of various hardnesses, such as iron ore, copper ore, gold ore, etc. Its powerful crushing capacity and stable performance greatly improve the crushing efficiency of ore, thereby reducing production costs. At the same time, the CJ409 jaw crusher has a large feed port size, which can accommodate larger ore blocks, further improving the crushing efficiency.

In the field of stone processing, CJ409 jaw crusher also performs well. It can easily crush various stones, such as granite, marble, limestone, etc., into stones of different particle sizes. These stones are widely used in construction, road paving, gardening and other fields. The crushing chamber design of CJ409 jaw crusher is reasonable, and the meshing angle is moderate, so that the material falls smoothly, the crushing efficiency is high, and the crushed stone particle size is uniform, which meets the needs of different customers.

In addition, CJ409 jaw crusher is also suitable for industrial sectors such as metallurgy, chemical industry, cement, etc. In the metallurgical industry, it can crush various metal ores into particle sizes suitable for smelting; in the chemical industry, it can be used to crush various chemical raw materials, such as coal, coke, etc.; in the cement industry, it can crush raw materials such as limestone into particle sizes suitable for producing cement.

CJ409 Jaw Crusher Advantages

Technological innovation, performance optimization

The design of the CJ409 Jaw Crusher incorporates the latest technical concepts. Its single toggle plate structure not only simplifies the mechanical structure, but also significantly improves the stability and durability of the equipment. This design enables the machine to more effectively disperse stress and extend its service life when it undergoes high-intensity crushing operations. Through carefully optimized mechanical design, CJ409 Jaw Crusher shows excellent performance, with a maximum compressive strength of up to 320Mpa, easily coping with the challenges of various hardness ores, whether it is hard iron ore or brittle limestone, it can achieve efficient crushing .

Efficient crushing, cost saving

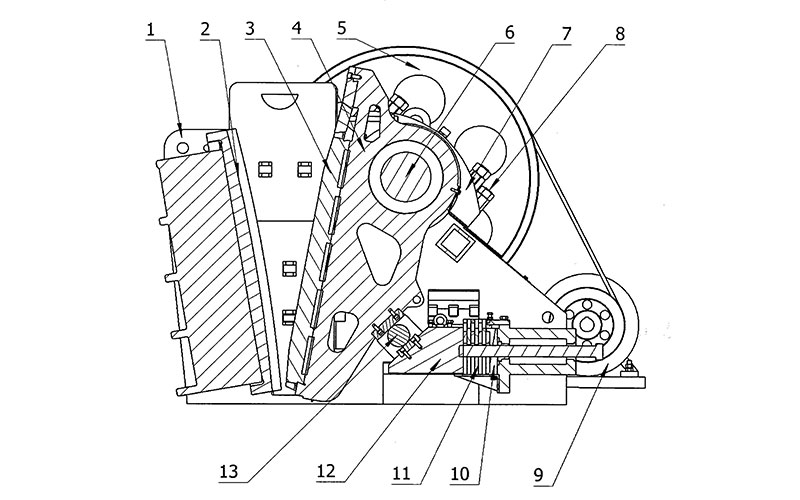

The core advantages of this model are its efficient crushing capacity and low cost per ton. CJ409 Jaw Crusher drives the belt and pulley through the motor, and then drives the movable jaw to move up and down through the eccentric shaft. This precise mechanical action ensures that the material can be crushed evenly and quickly. This working principle not only improves crushing efficiency, but also reduces energy consumption, greatly reducing the processing cost per ton of product. For mining companies and construction material manufacturers pursuing high efficiency and low cost, CJ409 Jaw Crusher is undoubtedly an ideal choice.

Easy maintenance and long-lasting

When it comes to equipment maintenance, the CJ409 Jaw Crusher also performs well. Its design fully considers user convenience, and its modular structure makes daily inspection and troubleshooting simple and easy. In addition, key components made of high-quality wear-resistant materials, such as movable jaws, toggle plates, etc., ensure that the equipment can still maintain good working condition under long-term, high-intensity operating conditions, extend the overall service life, and reduce Maintenance frequency and downtime.

Wide applicability to meet diverse needs

CJ409 Jaw Crusher has an extremely wide range of applications, from mining to construction waste treatment, from stone processing to metallurgical industries, it can be found. Whether it is processing large-sized rock blocks or ore particles that require fine crushing, the CJ409 can meet diverse production needs with its powerful crushing capacity and flexible operation.

CJ409 Jaw Crusher Principle

The working principle of CJ409 jaw crusher is based on the extrusion and crushing action of the jaw plate. It consists of two jaw plates, namely the fixed jaw plate and the swinging jaw plate. The swinging jaw plate is connected to the eccentric shaft through a connecting rod. The rotation of the eccentric shaft causes the swinging jaw plate to produce periodic reciprocating motion. The ore or rock to be crushed enters the crushing chamber from the feed port. With the reciprocating motion of the swinging jaw plate, the ore is clamped between the jaw plates and subjected to pressure. Under the extrusion of the jaw plates, the ore is gradually broken and crushed, and finally discharged through the discharge port at the bottom of the crushing chamber.

CJ409 Jaw Crusher Principle Parameters

| Capacity (by hour) | mtph | Feed opening | 895 x 660 mm (35 x 28 in.) mm |

| Motor power | 75 kW (100 hp) | Weight | 13,200 kg (29,100 lb) |

| Length | 2.55 m (101.00 in.) | Width | 1.88 m (74.00 in.) |

| Height | 2.38 m (94.00 in.) | Feed size | mm |