CJ815 Jaw Crusher Excellent Performance in Mining Industry

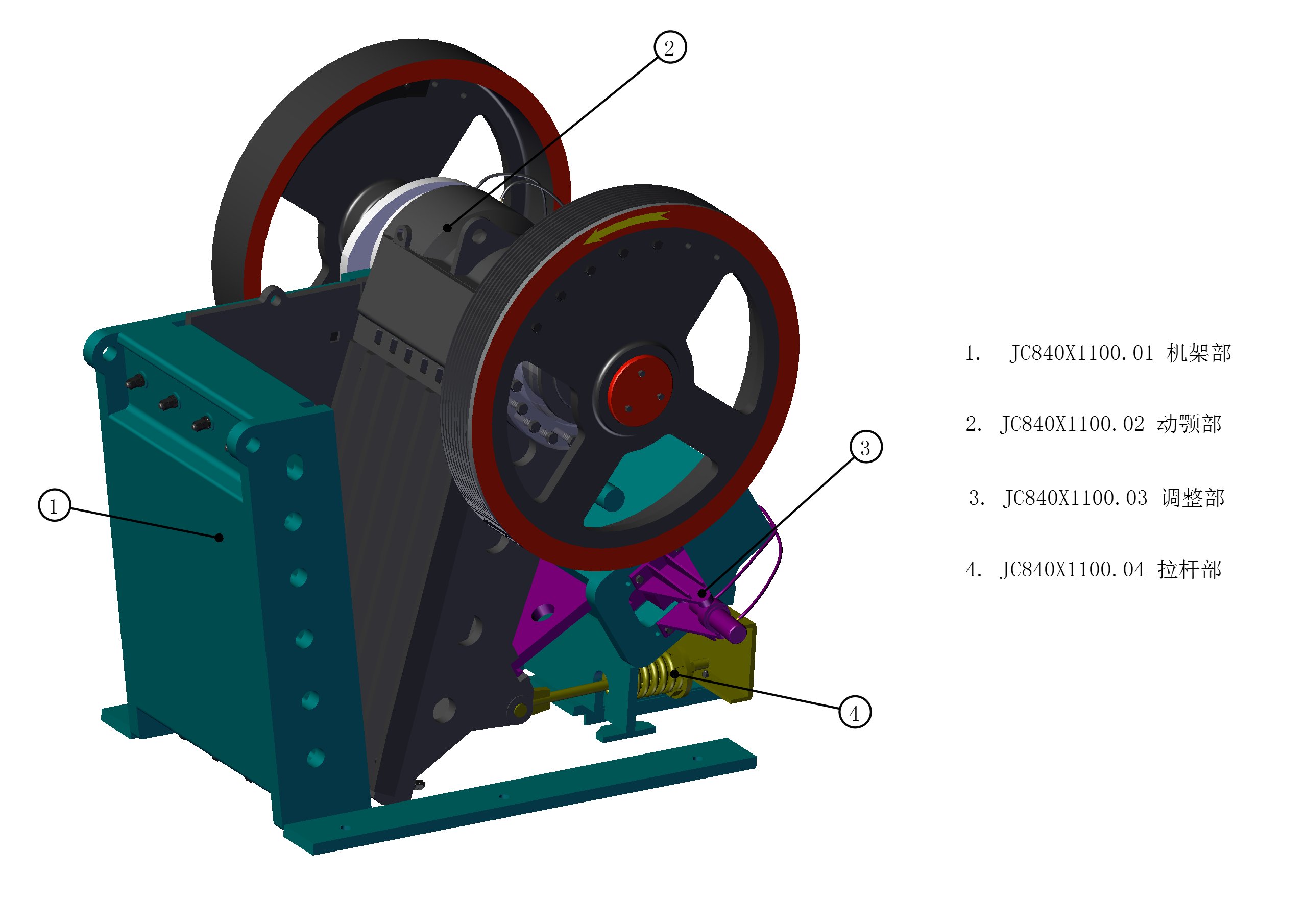

CJ815 Jaw Crusher achieves material crushing by clamping and squeezing between two hard surfaces. The movable jaw body moves independently of the load and forms the crushing chamber with the static jaw body and cheek plates. The material is clamped and crushed between the two jaws. The motor power is transferred to the eccentric shaft flywheel via a belt, and the eccentric shaft rotation and elbow plate movement drive the movable jaw body in an elliptical motion to complete the crushing.The CJ815 crusher has low wear on the jaw plates, reducing maintenance requirements, reducing downtime and maintaining efficient production. Manual and semi-hydraulic adjustment options are available to meet diverse needs. Widely used in mining, construction and other fields, crushing a variety of materials with high efficiency and stability, bringing significant economic benefits to users.

CJ815 Jaw Crusher Excellent Performance in Mining Industry Applications

Firstly, CJ815 jaw crusher plays an important role in metallurgy industry. In the metallurgical process, the ore needs to be crushed for subsequent smelting operations. with its large feed opening, high crushing ratio and stable performance, the CJ815 Jaw Crusher can effectively crush large ores into small pieces suitable for smelting, providing reliable raw material preparation for the metallurgical industry. Whether in the crushing of iron ore, non-ferrous metal ores or other metallurgical raw materials, CJ815 jaw crusher can show excellent crushing effect.

Secondly, in the mining industry, CJ815 jaw crusher is indispensable. The ore extracted from mines is often large in size and needs to be crushed for subsequent processing and utilisation. CJ815 jaw crusher, as a primary crushing equipment, is able to efficiently deal with ores of various hardnesses, providing a strong support for the production of mines. Its wear resistance and fatigue resistance enable the equipment to run continuously for a long time, reducing downtime and maintenance costs, and improving the productivity of mines.

In addition, in the building materials industry, CJ815 jaw crusher also has a wide range of applications. In the building materials industry, such as cement, concrete and other materials need to be used in the production of crushed raw materials, CJ815 Jaw Crusher can crush the large raw materials into a suitable size for production, providing high quality raw materials for the building materials industry. Meanwhile, its optimised crushing cavity and reasonable working parameters make the energy consumption in the crushing process effectively controlled, which is in line with the concept of green development of modern industry.

CJ815 Jaw Crusher Excellent Performance in Mining Industry Advantages

Excellent crushing effect and uniform product size

CJ815 Jaw Crusher has excellent crushing effect and ensures uniform size of crushed materials. It has a deep crushing chamber and no dead zone, which improves the feeding capacity and output. At the same time, because the equipment can achieve multiple crushing in the crushing process, the product size is more uniform, which meets the needs of different users for material size. This excellent crushing effect makes the CJ815 Jaw Crusher play an excellent role in applications that require high precision crushing.

Easy to operate and maintain

The CJ815 Jaw Crusher is easy to operate. The discharge opening is uniquely set up so that no shims need to be added or subtracted, and the discharge opening can be adjusted only by adjusting the machinery, making it easy and quick to operate. In addition, after continuous improvement and optimisation, the structure of the equipment has been simplified, making maintenance more convenient. The downtime for maintenance is greatly reduced, which improves the utilisation rate of the equipment. At the same time, the lubrication system is safe and reliable, the parts are easy to replace, and the maintenance workload is small, which further reduces the maintenance cost.

Strong adaptability and flexibility

CJ815 jaw crusher has strong adaptability and flexibility. It can work with the crushing chamber completely full or even overloaded, so it can be conveniently used in automated production lines. At the same time, its discharge opening has a wide range of adjustment to meet the requirements of different users. This flexibility and adaptability makes the CJ815 jaw crusher able to cope with a variety of complex crushing tasks and meet the diversified needs of users.

Energy saving and environmental benefits

The CJ815 Jaw Crusher excels in energy saving. Its cavity is in the form of deep cavity hyperboloid, which is matched with the structure of negative support, zero suspension, small eccentricity and high pendulum frequency, enabling the equipment to obtain high processing capacity while maintaining low abrasion consumption and low energy consumption. This design not only improves production efficiency, but also significantly reduces operating costs. At the same time, the jaw crusher also has certain environmental benefits because it generates less noise and dust during operation.

Solid structure and stable operation

CJ815 Jaw Crusher focuses on steel and stability in its structural design, and is made of high-strength materials, which ensures that the equipment can maintain stable operation even under harsh working conditions. The overall structure of the CJ815 Jaw Crusher is strong in steel and good in stability, which can resist the huge impact force generated during the crushing process and prolong the service life of the equipment. In addition, its simple structure also reduces the possibility of equipment failure and improves the reliability of operation.

CJ815 Jaw Crusher Excellent Performance in Mining Industry Working Principle

When CJ815 Jaw Crusher is working, the motor drives the belt and pulley, and the eccentric shaft drives the movable jaw up and down. When the movable jaw rises, the angle between the elbow plate and the movable jaw increases, which pushes the movable jaw plate close to the fixed jaw plate, and the material is crushed by squeezing and rubbing between the two jaw plates. When the movable jaw goes down, the angle becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of tie rod and spring, and the crushed material is discharged from the discharge port by gravity. The motor power is transmitted to the eccentric shaft flywheel through the belt, and the flywheel rotates through the elbow plate to drive the elliptical movement of the movable jaw body. When the movable jaw is close to the static jaw, the material is crushed by extrusion; when it leaves, the crushed material is discharged from the crushing chamber.

CJ815 Jaw Crusher Excellent Performance in Mining Industry Technical Parameters

| Feed opening | 1,500 x 1,300 mm | power | 200 kW |

| Feed size | 1,170 mm | Closed side setting range | 150 - 300 mm |

| Weight | 74,100 kg | Jaw plates | CC, ST, HD |