Crushing and Screening Equipment LT330D Mobile Cone Crusher

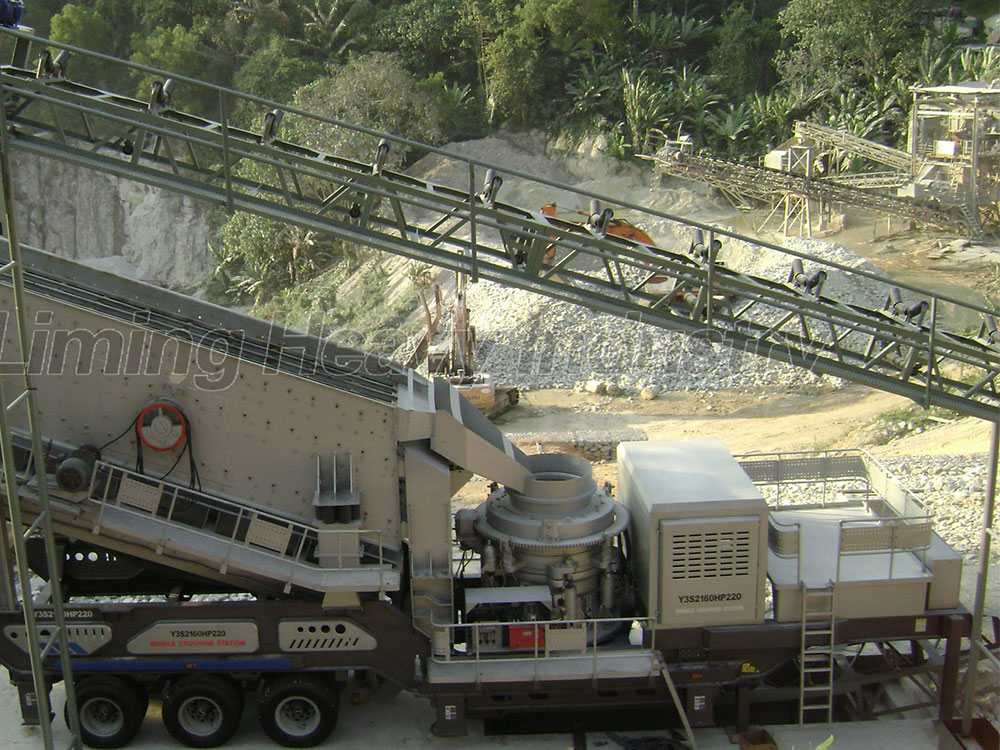

LT330D Mobile Cone Crusher is a highly efficient and multi-functional crushing and screening machine. Its all-electric design is not only green and environmentally friendly, but also perfectly integrates the cone crusher, triple-deck double inclination vibrating screen and the patented centrifugal conveyor, which makes the whole machine easy to transfer between different production sites. As the backbone of the multi-stage crushing process, the LT330D is capable of handling both medium and fine crushing, easily producing three standard end products. Together with the LT120E mobile jaw crushing plant, the LT330D forms an impeccable crushing line.

The LT330D is equipped with a reliable cone crusher with a wide range of eccentric distance and discharge opening options, which can easily meet all kinds of tough aggregate production challenges. Its automatic control system optimizes the crushing effect to the extreme, and the one-button operation design makes the operation easier. Meanwhile, the machine can be seamlessly connected with Metso IC system to realize remote monitoring and control, making production management more intelligent.

In addition, LT330D also excels in maintenance, with a safe and convenient design that makes maintenance work easier. The compact body design and reasonable transportation form factor make installation and commissioning faster, making it ideal for efficient contract crushing.

Crushing and Screening Equipment LT330D Mobile Cone Crusher Applications

In mining, it can easily cope with ores of various hardnesses, showing excellent crushing capacity and extreme adaptability to hard rocks. This not only improves the crushing efficiency of the ores, but also provides strong support for the subsequent smelting and processing procedures. Meanwhile, LT330D mobile cone crusher also plays an important role in the construction industry. It is able to convert materials such as construction waste and waste concrete into recycled aggregate, which provides high-quality raw materials for the production of new construction materials. This kind of recycling not only helps environmental protection, but also greatly improves the utilization rate of resources. In addition, LT330D mobile cone crusher also shows its high efficiency and stable crushing performance in the construction of highways, railroads and other infrastructures. It can provide high-quality filler and solid support for stone processing and roadbed filling processes, ensuring the smooth progress of infrastructure construction. In the metallurgical industry, LT330D mobile cone crusher also has a wide range of applications. It can deal with slag and other wastes produced in the smelting process, realizing the reuse of resources. At the same time, it can also be used to crush the raw materials needed for smelting, providing the right particle size for the smelting process and ensuring the smooth progress of the smelting process.

Crushing and Screening Equipment LT330D Mobile Cone Crusher Advantages

First of all, this customized host is designed for the development of mobile stations, with reliable performance and high output. Its energy utilization rate is also quite excellent, which undoubtedly brings higher economic benefits to users. In terms of maintenance and adjustment, the machine is designed to be extremely simple, enabling users to easily carry out routine maintenance and adjustment work.

Secondly, the overall modular design is another highlight of the host. This design makes the general interchangeability greatly enhanced, when there is an order, can be quickly assembled into the required mobile station model, thus greatly shortening the production cycle, to meet the urgent needs of customers for rapid delivery.

In terms of lubrication, the mainframe adopts thin oil self-lubrication, which not only has good lubrication effect, but also has a long maintenance cycle. Users only need to replace the lubricant once every 8 months to ensure the stable operation of the equipment, thus saving lubricant and labor costs.

In addition, foundationless installation is also a major advantage of this mainframe. All the components are completely on-board, no need to dismantle the parts for transportation, which saves users the process of on-site installation. Meanwhile, the reasonable adjustable fixed leg design realizes the real foundationless installation, which provides great convenience for users.

In terms of convenience and flexibility, the mainframe also performs well. The design of no external belt conveyor eliminates the need for cranes and erection of belt conveyors on site, thus allowing for quick installation and commissioning. When transferring to other sites, the mainframe can be put into production within 24 hours, fully demonstrating the superiority of the mobile station's convenience and flexibility.

Finally, the host also adopts a new on-board integrated intelligent automatic control system. This system makes the operation, maintenance and adjustment of the crushing process more convenient and accurate, providing users with a more intelligent experience.

Crushing and Screening Equipment LT330D Mobile Cone Crusher Working Principle

When the material enters the crusher, the motor drives the eccentric sleeve to rotate through the transmission device. This rotary motion makes the moving cone connected with the eccentric sleeve produce a rotary motion, that is, the moving cone swings around a fixed point. In this process, the surface of the moving cone will sometimes close to the inner surface of the fixed cone, and sometimes away. When the moving cone is close to the fixed cone, the material between the two cones will be subjected to strong extrusion, rubbing and bending, thus realizing crushing.

The crushed material will be discharged from the discharge opening of the crusher under the joint action of gravity and the rotary motion of the moving cone. The material that fails to meet the particle size requirement will remain in the crushing chamber to be further crushed and polished until it reaches the required particle size.

It is worth noting that the LT330D Mobile Cone Crusher has been designed with the actual needs of users in mind. Its crushing mechanism is carefully optimized to achieve efficient and stable crushing effect. Meanwhile, the operation and maintenance of the equipment are extremely easy, providing great convenience for users.

Crushing and Screening Equipment LT330D Mobile Cone Crusher Technical Parameters

| Feed opening | 238 mm (9.37'') | Engine | 700 kVA (630 hp) |

| Weight | 71,000 kg (156,600 lbs) | Width | 3,500 mm (11'5") |

| Height | 3,900 mm (12'10") | Length | 20,500 mm (67'4") |