CS420 Cone Crusher: a crushing tool with large feed and high production capacity

CS420 cone crusher, as a medium-sized crushing equipment with excellent performance, shows its unique advantages in processing capacity and crushing effect. In terms of processing capacity, CS420 cone crusher is divided into two types: standard type and short head fine crushing type. The processing capacity of the standard type ranges from 22-128 tonnes/hour, which is suitable for crushing materials with medium hardness; while the short-head fine crushing type is more powerful, with a processing capacity of 70-168 tonnes/hour, which is especially suitable for high hardness materials or scenes requiring fine crushing treatment. In addition, the size of the feed opening of the equipment is also different, the standard type ≤ 135mm, short head type ≤ 240mm, some models even support ≤ 369mm larger materials, further broadening its scope of application. The CS420 Cone Crusher also excels in discharge opening adjustment and discharge size control. With a wide range of discharge opening adjustments, from 4-38mm, users can make flexible adjustments according to actual needs. The discharge size can be controlled between 3-64mm, which ensures the uniformity of the crushed product size and quality stability. This advantage is due to the laminar crushing technology adopted by the equipment, through the optimisation of the cavity type and pendulum frequency, which not only improves the crushing efficiency, but also effectively reduces the proportion of needle-flake particles, so that the crushed products are more in line with the market demand.

In order to meet the needs of different materials and working conditions, the CS420 Cone Crusher also supports a variety of cavity configurations, such as ultra-coarse, medium-coarse, fine, and so on. Users can choose the appropriate cavity type for crushing operation according to the hardness and particle size distribution of materials to achieve the best crushing effect and economic benefits.

In terms of equipment design, CS420 Cone Crusher adopts single-cylinder hydraulic design. This innovative design not only simplifies the structure of the equipment, but also integrates hydraulic adjustment of the discharge opening and overload protection function. Users can quickly adjust the discharge opening by simple operation, which greatly improves the working efficiency. Meanwhile, when the equipment encounters an overload situation, the hydraulic system will automatically activate the protection mechanism to avoid damage to the equipment, ensuring the safety and stability of production. In practical application, CS420 cone crusher is often combined with jaw crusher (e.g. PE600×750) or sand making machine (e.g. DLKZS1314) to form a multi-stage crushing line. Such a combination not only improves the crushing efficiency, but also ensures the stability and continuity of the crushing process. The jaw crusher, as the primary crushing equipment, is responsible for crushing large materials into smaller sizes, and then these materials are fed into the CS420 cone crusher for further fine crushing. Finally, the sand making machine is responsible for processing the finely crushed materials into sand or stone that meets the requirements. Such a multi-stage crushing line not only improves the production efficiency, but also ensures the quality and particle size distribution of the products.

CS420 Cone Crusher: a crushing tool with large feed and high production capacity Applications

Mining industry: Ore is usually high in hardness and needs to be crushed to the right size for subsequent processing, the CS420 Cone Crusher can easily cope with the crushing of iron ore, copper ore, limestone and other high hardness ores by virtue of its sturdy structural design. Its optimised crushing mechanism ensures high crushing efficiency and stable product quality, providing reliable production guarantee for mining enterprises. During the mining process, CS420 Cone Crusher is not only capable of handling ores of various hardnesses, but also capable of adjusting the crushing chamber type and pendulum frequency according to the actual needs to optimise the crushing effect. This flexibility makes the CS420 Cone Crusher extremely valuable in the mining industry.

Building materials industry: Aggregate and sand are indispensable materials in the construction of buildings, roads, bridges and other infrastructures, and the CS420 Cone Crusher is capable of crushing all kinds of rocks and construction wastes and processing them into aggregates and sand that meet the requirements. Its efficient crushing capacity and stable finished product quality meet the demand for high quality raw materials in the building materials industry. In the building materials industry, CS420 cone crusher usually forms a multi-stage crushing line with jaw crusher and sand making machine to achieve efficient crushing and particle size control of materials. This combination not only improves the production efficiency, but also ensures that the quality and particle size distribution of the products meet the market demand.

Metallurgical industry: Crushing of metallurgical raw materials is an important part of the smelting process. the CS420 Cone Crusher is able to crush all kinds of metallurgical raw materials into the appropriate particle size, improving smelting efficiency and product quality. Users can choose the appropriate cavity type for crushing operation according to the hardness and particle size distribution of materials to achieve the best crushing effect and economic benefits. In terms of equipment design, CS420 Cone Crusher adopts single-cylinder hydraulic design. This innovative design not only simplifies the structure of the equipment, but also integrates hydraulic adjustment of the discharge opening and overload protection function. Users can quickly adjust the discharge opening by simple operation, which greatly improves the working efficiency.

Meanwhile, when the equipment encounters an overload situation, the hydraulic system will automatically activate the protection mechanism to avoid damage to the equipment, ensuring the safety and stability of production. In practical application, CS420 cone crusher is often combined with jaw crusher (e.g. PE600×750) or sand making machine (e.g. DLKZS1314) to form a multi-stage crushing line.

CS420 Cone Crusher: a crushing tool with large feed and high production capacity Advantages

Efficient processing and flexible adjustability

This crushing plant has been designed with high processing efficiency and flexible adjustment in mind. The standard model has a wide range of capacities from 22 to 128 tonnes/hour, while the short-head fine crushing model is even more powerful, with a capacity of 70-168 tonnes/hour. With the optimisation of some of the configurations, the capacity of the plant can even soar to an amazing 1270 t/h, fully meeting the needs of large-scale crushing operations.

In order to meet different material characteristics and crushing requirements, the plant supports a variety of chamber configurations, such as standard and short head. This flexibility enables the plant to easily adapt to various application scenarios from coarse to fine crushing. In addition, its discharge opening is adjusted by an advanced hydraulic system with a wide range of adjustment from 4mm to 38mm, thus ensuring that the discharge size can be accurately controlled between 3-64mm, which meets the user's needs for a wide range of particle sizes.

Laminar crushing and high quality granularity guarantee

In terms of crushing principle, the machine adopts optimised cavity and pendulum frequency design to achieve multi-layer material crushing. This type of crushing not only improves the crushing efficiency, but also significantly reduces the proportion of needle-flake particles, making the discharge more uniform, with a higher proportion of cubic. This feature makes the equipment particularly suitable for high standard sand and gravel aggregate production, and can meet the high requirements of users for the finished product particle shape.

Advanced hydraulic system and safety guarantee

The equipment adopts single-cylinder hydraulic design, which integrates various functions such as discharge opening adjustment, overload protection and automatic cavity cleaning. This design not only simplifies the operation process, but also improves the response speed of the equipment. The working pressure of the hydraulic system is between 0.3-0.5MPa, which ensures the stable operation of the equipment. Meanwhile, the equipment is also equipped with a double pointer differential pressure gauge to monitor the status of the filter in real time, ensuring the clean and efficient operation of the hydraulic system.

In terms of safety and security, the equipment has excellent performance. When encountering abnormal conditions such as excessive iron, the equipment can automatically release foreign objects and restore the discharge port, effectively avoiding damage to the equipment. In addition, the equipment is also equipped with an automatic power-off protection and alarm function triggered by abnormal working conditions, which further ensures the safety of the operator and the stable operation of the equipment.

Reliable structure and convenient maintenance

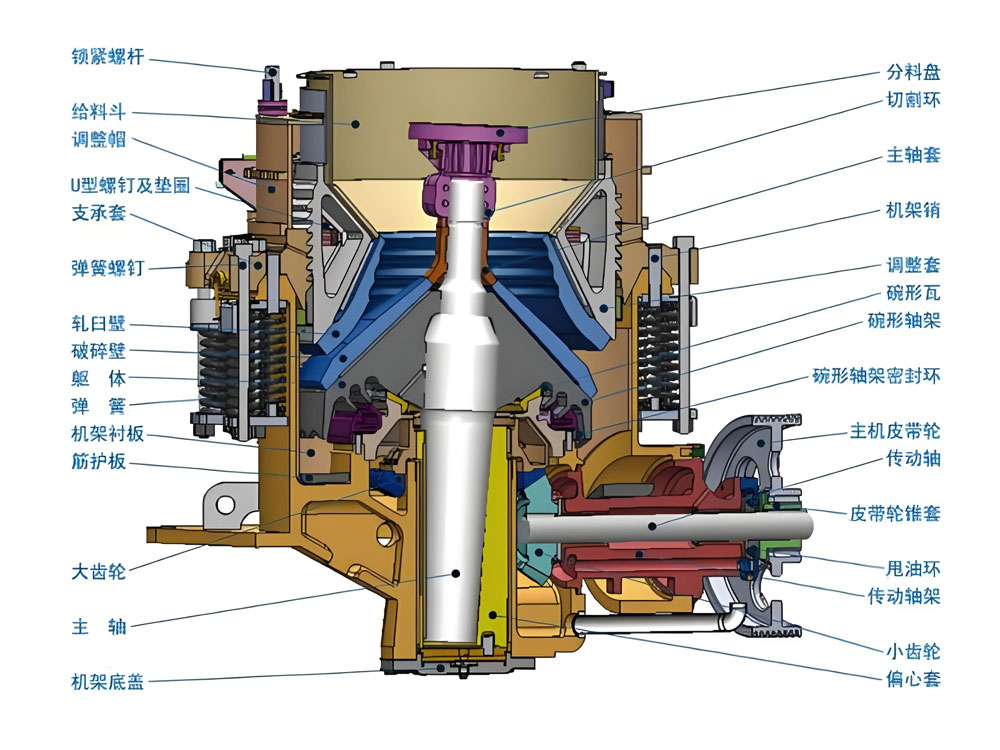

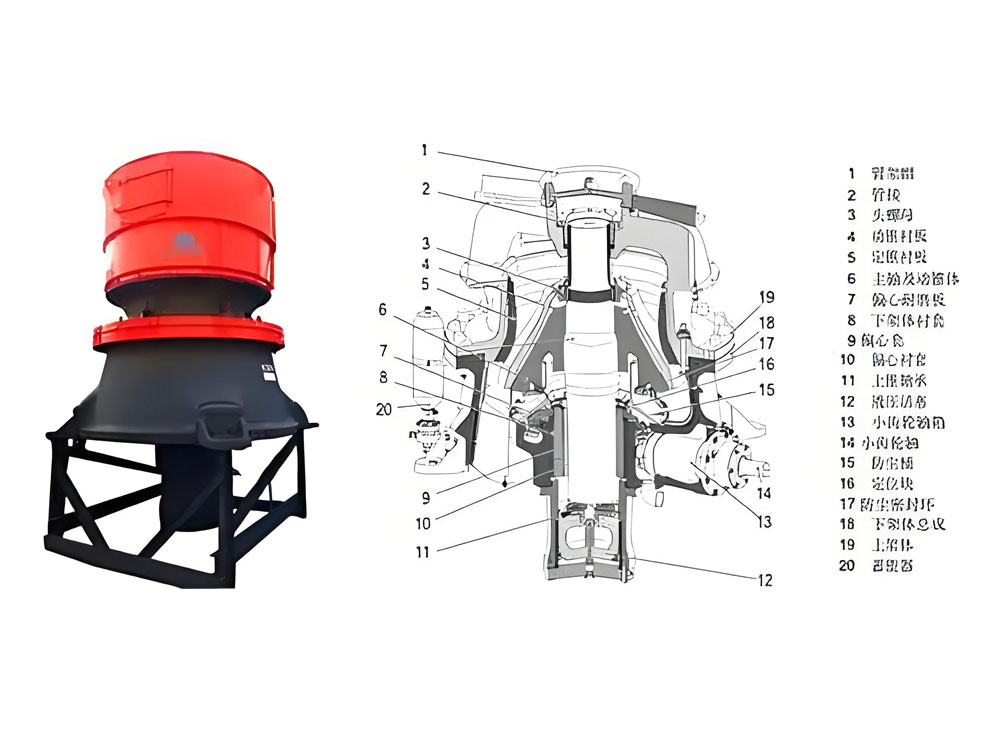

In terms of structural design, the equipment adopts a large-diameter spindle and cast steel body structure, which can withstand high impact loads and ensure the stability and durability of the equipment. The gear transmission system adopts high-precision bevel gears, which not only has low noise, but also has a long service life, reducing the maintenance cost of the equipment.

The machine also excels in terms of maintenance. All key components, such as the moving cone, fixed cone, etc., support top or side disassembly, making maintenance work more convenient and efficient. In addition, the machine is equipped with an independent thin oil lubrication system, which provides double protection for the bearings and further extends the service life of the machine.

Energy saving and low operating costs

The machine also excels in terms of energy consumption. The standard motor power is 90kW, while the high capacity model supports 75-400kW motor configurations. This design not only ensures that the machine has sufficient power output, but also achieves economical energy consumption. In practice, this equipment can significantly reduce the user's operating costs and improve economic efficiency.

CS420 Cone Crusher: a crushing tool with large feed and high production capacity Working Principle

This crushing plant adopts a unique single-cylinder structure, and its working principle is mainly based on the principle of extrusion crushing to achieve the crushing treatment of materials. In this sophisticated design, the moving cone plays a crucial role. It performs a series of periodic rotary oscillating movements driven by a well-designed eccentric sleeve. This movement creates a powerful crushing zone between the moving cone and the stationary cone, and any material entering the crushing chamber is subjected to strong impact and crushing action, resulting in effective crushing.

To drive this complex crushing mechanism, the motor is closely connected to the eccentric sleeve via a pulley or coupling, ensuring that the sleeve rotates smoothly and efficiently. As the eccentric sleeve rotates, it drives the main shaft and the cone in a pendulum motion around a fixed point. This pattern of motion causes the surface of the cone to move periodically closer to or further away from the cone, thus achieving continuous crushing of the material.

The materials enter the crushing chamber from the top of the crusher, and as soon as they enter this area, they are subjected to strong squeezing, bending and grinding forces between the moving cone and the fixed cone. These combined forces cause the material to be gradually crushed into smaller particles. Once the materials reach the required size, they will be discharged smoothly from the bottom discharge port of the crusher by gravity. Those materials that do not reach the required size will remain in the crushing chamber for further crushing until they meet the requirements. The crusher also has a built-in spring-loaded compression mechanism. The main purpose of this design is to protect the equipment from unbreakable materials. When some hard foreign objects (such as metal pieces) accidentally enter the crushing chamber, the spring will be compressed and deformed, thus enlarging the discharge opening, so that these foreign objects can be discharged smoothly, avoiding damage to the equipment. Overall, this crushing plant achieves fast and effective crushing of materials with its unique single-cylinder structure and efficient crushing principle of extrusion. Meanwhile, its built-in spring compression mechanism also provides a strong guarantee for the stable operation of the equipment. Whether dealing with hard ores or other types of materials, this crushing plant can show its excellent performance and reliability.

CS420 Cone Crusher: a crushing tool with large feed and high production capacity Technical Parameters

| Max. feed size | 267.0 mm | Weight | 7,188 kg |

| Power | 90 kW | Capacity | 170 tph |

| Eccentric throw range | 13.0 - 35.0 mm | Closed side setting range | 16.0 - 25.0 mm |