CS840i Stationary Cone Crusher

The CS840i crushing equipment is particularly suitable for the secondary and tertiary crushing links in metal mines and construction sand and gravel processing. Its powerful crushing capacity and wide applicability, especially when processing medium-hard materials such as river pebbles, show excellent performance. With its high output and stable operation performance, the CS840i has become an ideal choice for high-quality machine-made sand and gravel production, providing solid and reliable support for many engineering projects.

The CS840i adopts the advanced lamination crushing principle. The application of this principle enables the equipment to use energy more effectively and improve crushing efficiency during the crushing process. Through the carefully designed cavity and optimized crushing stroke, the CS840i not only significantly improves the crushing efficiency, but also ensures the maximum output. At the same time, this design also effectively reduces the generation of needle-like stones, making the finished product particle size more uniform, meeting the market demand for high-quality sand and gravel.

In terms of intelligence, the CS840i is equipped with an advanced intelligent control system. This system can monitor the operating status of the equipment in real time, including key parameters such as motor current, bearing temperature, vibration, etc., so as to timely discover and deal with potential problems and ensure the stable operation of the equipment. In addition, the intelligent control system can automatically adjust the crushing parameters and optimize the crushing performance according to production needs, further improving the production efficiency and product quality of the equipment. At the same time, intelligent management also extends the service life of the equipment and reduces maintenance costs.

In terms of maintenance convenience, the CS840i also performs well. All its components can be disassembled and assembled from the top or side, which greatly simplifies daily maintenance and overhaul work. Operators can easily replace and repair components without tedious disassembly work, thereby reducing maintenance costs and time. This convenience not only improves the utilization rate of the equipment, but also provides a strong guarantee for the production and operation of the enterprise. In order to ensure the durability and stable operation of the equipment, the CS840i adopts a large-diameter spindle and a heavy-duty main frame. This design enables the equipment to withstand greater crushing force and impact force, ensuring long-term stable operation. At the same time, the equipment is also equipped with an independent thin oil lubrication system to provide sufficient lubrication and cooling for key components, further extending the service life of the equipment.

CS840i Stationary Cone Crusher Applications

CS840i crushing equipment has demonstrated its powerful crushing capacity and wide application value in many industrial fields, especially in the mining industry, construction field, steel production, chemical raw material processing, hydropower and highway construction.

In the mining industry, CS840i is mainly used for the crushing of metal ores. Faced with ores with higher hardness such as iron ore, copper ore, and gold ore, CS840i can easily crush large pieces of ore into a particle size suitable for subsequent mineral processing with its powerful crushing capacity and high output. This not only improves the efficiency of mineral processing, but also effectively improves the metal recovery rate, bringing significant economic benefits to mining companies. At the same time, the stable operation performance of CS840i also ensures the continuity and stability of mine production.

In the construction field, CS840i also plays an indispensable role. It is widely used to process building stones such as limestone, granite, and basalt to produce high-quality gravel and machine-made sand. These aggregates have been widely used in engineering projects such as concrete production and road paving, meeting the demand for high-quality sand and gravel in construction projects. The precise crushing capacity and particle size control function of CS840i ensure that the aggregate produced is of uniform particle size and stable quality, providing strong guarantee for the quality of construction projects.

In steel production, CS840i also plays an important role. It is used to crush and pre-treat raw materials such as iron ore and coke to ensure that the particle size of the raw materials meets the requirements of blast furnace ironmaking. This link is crucial to ensure the smooth progress of the metallurgical production process. The efficient crushing capacity and stable operation performance of CS840i ensure the timely supply and quality stability of raw materials, providing strong support for the efficient operation of steel production.

CS840i also performs well in the field of chemical raw material processing. It can crush chemical raw materials such as gypsum and salt mines to meet the specific particle size requirements in chemical production. This function provides chemical companies with more flexible and efficient raw material processing methods, which helps to improve the quality and production efficiency of chemical products.

In hydropower and highway construction, CS840i also plays an important role. It is used to crush hard materials such as river pebbles, granite, and diabase to produce aggregates that meet engineering requirements. These aggregates have been widely used in the construction of hydropower station dams and roadbed paving, ensuring the smooth progress of the project quality and progress. The precise crushing capacity and stable operation performance of CS840i provide reliable technical support for hydropower and road construction.

CS840i Stationary Cone Crusher Advantages

High-efficiency crushing capacity

The CS840i crushing equipment has achieved a significant improvement in crushing efficiency and output through its unique cavity design and carefully calculated speed and stroke combination. This design not only optimizes the energy transfer during the crushing process, but also reduces unnecessary energy consumption, thereby ensuring the efficient operation of the equipment. The application of its laminated crushing principle has significantly increased the proportion of cubes in the crushed product, greatly reduced needle-like stones, and made the particle size distribution more uniform, meeting the market demand for high-quality crushed products.

Intelligent control system

The CS840i is equipped with an advanced intelligent control system, which can monitor the operating status of the equipment in real time, including key parameters such as motor current, bearing temperature, and vibration, so as to promptly detect and deal with potential problems and ensure the stable operation of the equipment. In addition, the intelligent control system can automatically adjust the crushing parameters such as the size of the discharge port and the crushing stroke according to production needs to optimize the crushing performance and further improve the production efficiency and product quality of the equipment. The design of the hydraulically adjusted discharge port makes operation more convenient, while the overload protection function further improves the stability and safety of the equipment and ensures the continuous operation of the production line.

Maintenance convenience

CS840i also performs well in maintenance convenience. All its components can be disassembled and assembled from the top or side. This design greatly simplifies daily maintenance and repair work, reducing maintenance costs and time. The introduction of the hydraulic cavity cleaning system makes it possible to quickly clean the crushing cavity under load, reducing production losses caused by shutdown cleaning. This design not only improves the utilization rate of the equipment, but also provides a strong guarantee for the production and operation of the enterprise.

High reliability

In order to ensure the durability and stable operation of the equipment, CS840i adopts a large-diameter main shaft and a heavy-duty main frame. This design enables the equipment to withstand greater crushing force and impact force, ensuring long-term stable operation. At the same time, the equipment is also equipped with an independent thin oil lubrication system to provide sufficient lubrication and cooling for key components, further extending the service life of the equipment. The design of the iron protection device can automatically release non-crushed objects and reset, effectively avoiding equipment damage caused by the entry of foreign objects, and ensuring the safe and stable operation of the production line.

Energy saving and environmental protection

CS840i has also made significant contributions to energy saving and environmental protection. By optimizing the crushing process and adopting advanced energy-saving technology, the equipment reduces energy consumption during operation, while reducing noise and dust emissions, meeting environmental protection standards. The design of the thin oil lubrication system not only improves the service life of the equipment, but also reduces production losses caused by downtime, further improving the economic benefits of the equipment.

Strong adaptability

CS840i is also very adaptable and can handle materials of various hardnesses, such as river pebbles, granite, diabase, etc. This makes it widely used in mining, construction, highways, metallurgy, hydropower and other fields. Whether in the crushing of metal ores or in the processing of building stones, CS840i can demonstrate excellent performance and stable operation, providing strong support for the production and operation of enterprises.

CS840i Stationary Cone Crusher Working Principle

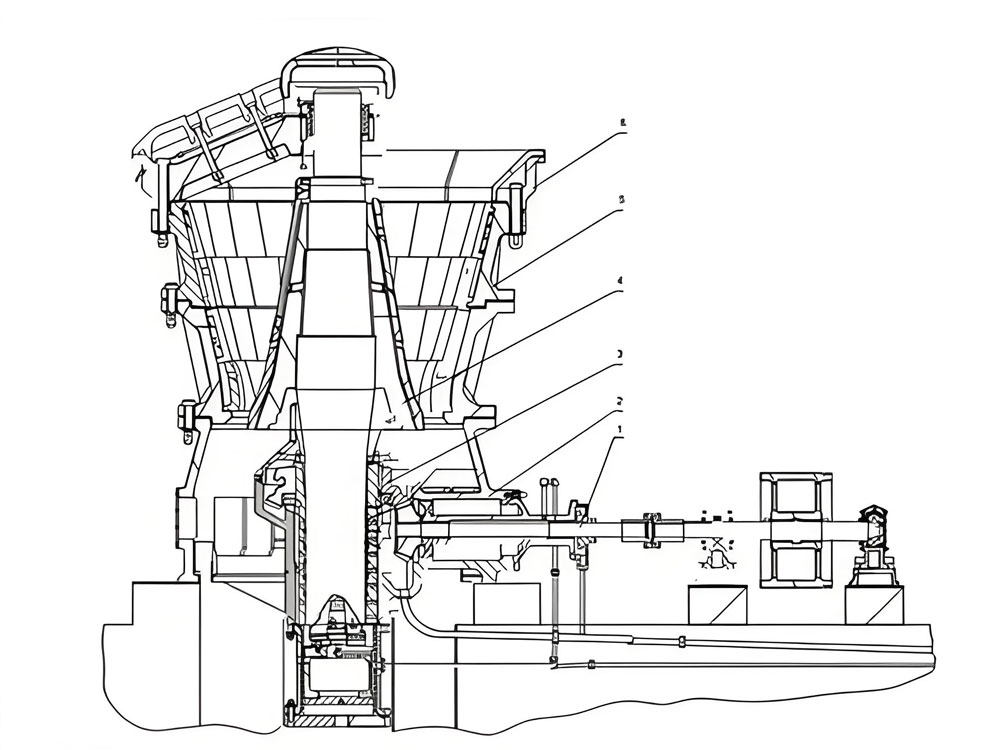

After the material enters the CS840i crusher, it undergoes a series of precise and efficient crushing processes. First, the material is thrown into the crusher from the top and falls freely into the crushing chamber carefully constructed by the fixed cone and the moving cone. This design ensures that the material can be evenly distributed in the crushing chamber, laying the foundation for subsequent efficient crushing.

The moving cone, as a key component in the crushing process, performs complex rotational swinging motions driven by the eccentric sleeve. This motion mode causes the material to be continuously squeezed, impacted and bent between the fixed cone and the moving cone, thereby achieving an efficient crushing effect. The eccentric sleeve is driven by the motor, and transmits power through the pulley or coupling, thereby driving the main shaft and the moving cone to eccentrically swing. This periodic movement of approaching and moving away from the fixed cone forms a continuous crushing action, ensuring that the material can be crushed evenly and effectively.

The CS840i crusher adopts advanced laminated crushing technology, which is the key to its efficient crushing. In the crushing chamber, the material is subjected to multi-layer extrusion and impact. This multi-layer crushing method not only significantly improves the crushing efficiency, but also makes the finished product more uniform in particle size, effectively reducing the generation of needle-like stones. This optimized crushing effect meets the market's stringent demand for high-quality crushing products.

After the crushing is completed, the material falls naturally under the action of gravity and is discharged smoothly through the discharge port at the bottom. The CS840i crusher is equipped with an advanced hydraulic system that can automatically adjust the size of the discharge port according to production needs, thereby achieving precise control of the particle size of the finished product. In addition, when encountering unbreakable objects, the hydraulic system can respond quickly to achieve overload protection, effectively avoiding damage to the equipment and ensuring the safe operation of the production line.

In order to ensure the long-term and stable operation of key components such as the main shaft and bearings, the CS840i crusher adopts an independent thin oil lubrication system. This system provides sufficient lubrication and cooling for key components, effectively extending the service life of the equipment. At the same time, the introduction of the hydraulic cavity cleaning system enables the crushing cavity to be quickly cleaned under load, greatly reducing downtime and improving equipment utilization.

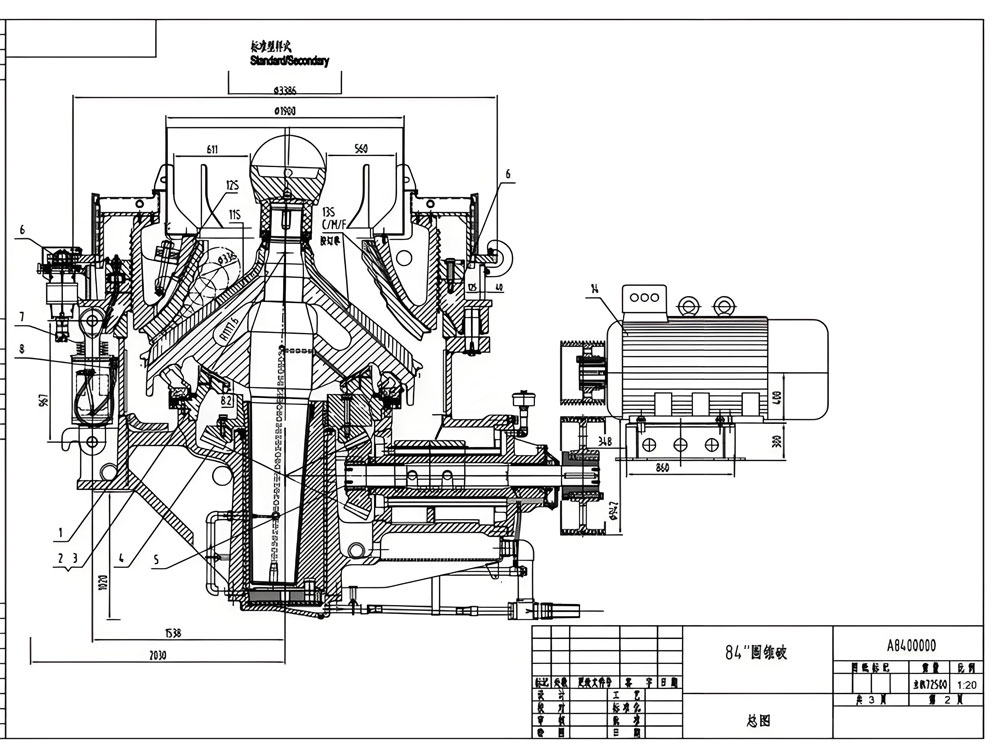

CS840i Stationary Cone Crusher Technical Parameters

| Max. feed size | 431 mm | Capacity | 400 t/h |

| Power | 330 kW | Eccentric throw range | 24 - 48 mm |

| Weight | 25,794 kg | Closed side setting range | 22 - 70 mm |