CV215 Impact Crusher

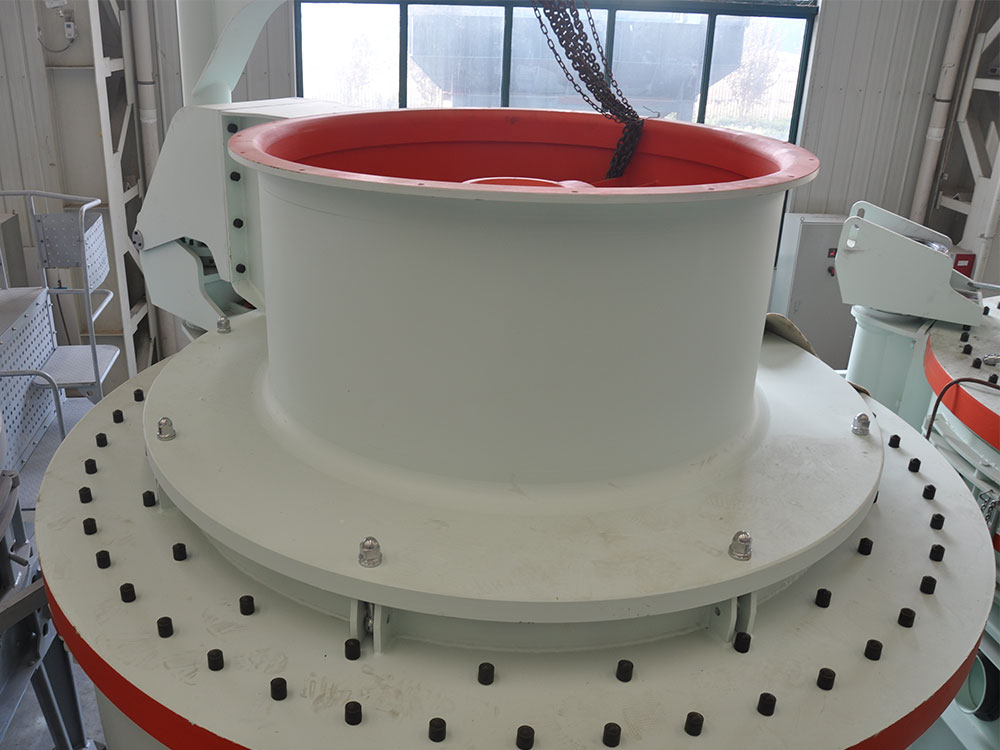

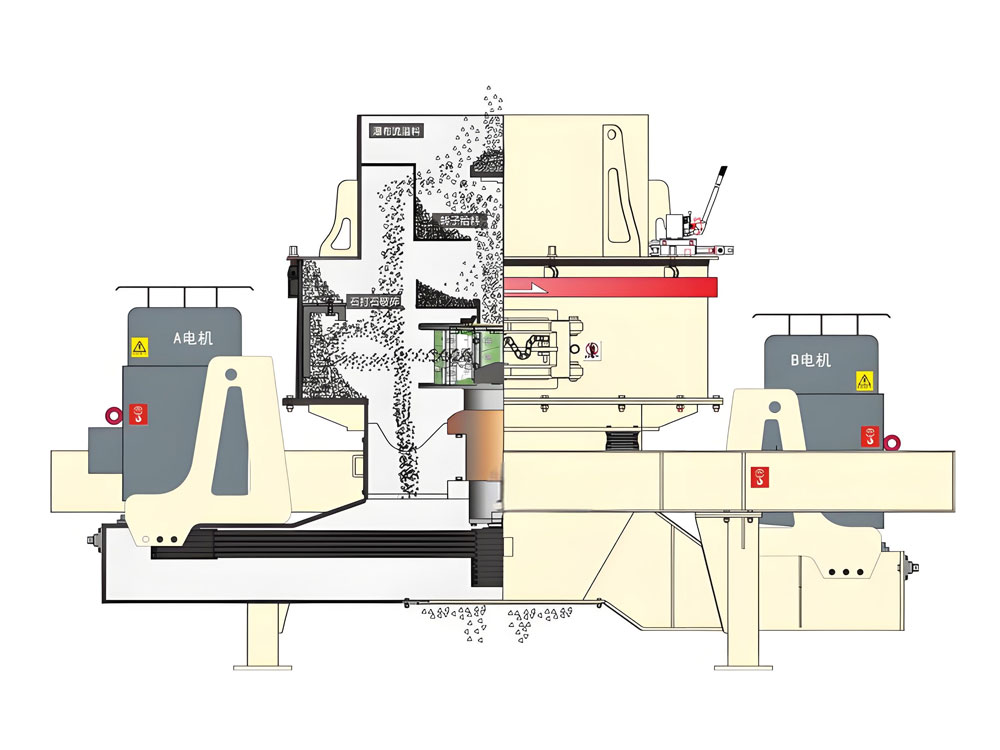

CV215 impact crusher, as a fixed vertical shaft impact crusher designed for tertiary and quaternary crushing applications, is widely praised in the industry for its exquisite design and excellent performance. The core components of the crusher are carefully laid out, including the feed hopper, distributor, vortex crushing chamber, impeller, main shaft assembly, base transmission device and motor, etc., each of which plays a vital role.

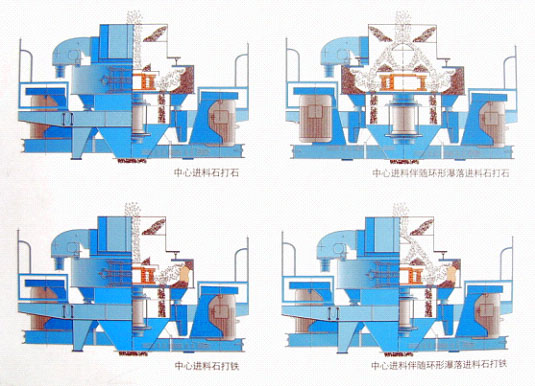

Its working principle is based on the advanced "stone-on-stone" impact crushing technology. After the material enters the crusher from the feed hopper, it is first cleverly distributed by the distributor and evenly divided into two parts. One part of the material enters the high-speed rotating impeller, is rapidly accelerated and thrown out at a very high speed, and collides with the other part of the naturally falling material in the air. This violent impact collision realizes the efficient crushing of the material, which is not only high in crushing efficiency, but also excellent in crushing effect.

The CV215 impact crusher adopts a unique material self-lining technology. This design greatly reduces the wear of vulnerable parts, such as the impact plate, thereby extending the service life of the equipment. At the same time, this technology also effectively reduces energy consumption and increases production, making the crusher perform well when handling hard, highly abrasive materials. The crushing capacity of CV215 is extremely powerful, and it can easily crush a variety of hard and brittle materials, such as rocks, concrete, metallurgical slag, etc. This makes it widely used in the production of construction sand and road sand and gravel. The crushed product is cubic in shape, with a large bulk density and extremely low iron pollution, which is very suitable for the production needs of high-quality aggregates. In addition, the structural design of the CV215 impact crusher is also extremely compact, and it is extremely easy to install and maintain. The replacement of wear-resistant parts is quick and simple, which greatly reduces downtime and improves the utilization rate of equipment. This design not only reduces the user's maintenance cost, but also brings higher economic benefits to users.

CV215 Impact Crusher Applications

In the field of ore processing, it can crush various ores, such as limestone, granite, basalt, etc., and is particularly suitable for processing medium-hard, extra-hard and abrasive materials. As a pre-grinding equipment, in the fine crushing and coarse grinding of ore, the equipment shows excellent energy-saving effect, significantly reduces energy consumption and improves production efficiency.

In the field of construction, this equipment also plays an important role. It can be used to produce high-quality artificial sand and building aggregates to meet the needs of high-standard building sand. At the same time, in building demolition and concrete crushing, the equipment can crush waste materials into small pieces, which is convenient for cleaning and reuse, and realizes the effective recycling and reuse of resources.

In the metallurgical industry, this crushing equipment also shows its unique advantages. It can crush metallurgical slag, such as silicon-manganese alloy, ferrosilicon blocks, etc., to improve the utilization rate of resources. In addition, in mineral processing, the equipment can crush, screen and grind ores, effectively extract valuable minerals, and provide strong support for the development of the metallurgical industry.

In the field of environmental protection, this equipment also has outstanding performance. It can process construction waste, waste concrete, etc., crush these wastes into renewable resources, and reduce environmental pollution. At the same time, in earthwork projects, the stones crushed by this equipment can be used to build infrastructure such as roads, railways, bridges, etc., contributing to urban construction and transportation development.

Chemical and building materials production fields. It can crush refractory materials, glass raw materials, etc. to meet the special needs of these industries for raw materials. In cement production, this equipment can crush raw materials such as limestone, improve production efficiency, reduce production costs, and provide strong guarantees for the development of the cement industry.

Finally, this equipment is also used to produce road construction materials such as highway road surfaces, cushion materials, asphalt concrete and cement concrete aggregates. These materials have the characteristics of high strength, high stability and high durability, which can meet the high standards of road and bridge construction and provide strong support for the safety and stability of transportation infrastructure.

CV215 Impact Crusher Advantages

Efficient crushing

Efficient crushing technology is an indispensable part of the modern industrial field. It adopts the impact principle and a strong crushing ratio to efficiently process medium-hard, extra-hard and abrasive materials such as limestone, granite, basalt, etc. This crushing method not only improves production efficiency, but also ensures the uniformity and fineness of the material during the crushing process. The single-machine processing capacity of this crushing equipment covers a wide range of 30-800t/h, which can meet the production needs of different scales. Its crushing efficiency is high, and its energy consumption is reduced by 30% compared with traditional equipment, which significantly improves energy utilization efficiency and reduces production costs.

Excellent finished product shape

In terms of finished product shape, the equipment performs well. The output particle shape is cubic and the needle-like content is low, which is very suitable for the production of high-standard construction sand and road aggregates. By adjusting the impeller speed and the gap between the impact plates, users can flexibly control the output particle size to meet different production needs and realize customized production.

Strong wear resistance

The wearing parts are made of highly wear-resistant materials, such as high manganese steel, with a long service life, reducing the replacement frequency and reducing downtime. At the same time, the design of self-impact crushing between materials reduces direct contact with metal components, further extending the service life of the equipment.

Environmental protection and energy saving

The closed crushing chamber design effectively reduces dust spillage and meets the green mining standards. At the same time, the equipment is also equipped with a high-efficiency dust removal device, and the dust emission concentration is less than 10mg/m³, which has a significant environmental protection effect and reduces pollution to the environment.

Intelligence and automation

The equipment is equipped with a PLC control system, which realizes real-time monitoring of the equipment status and fault warning, and improves production efficiency and safety. According to the characteristics of the material, the equipment can automatically adjust the impeller speed and gap, optimize the crushing efficiency, and realize intelligent production.

Simple structure and convenient maintenance

The equipment has a reasonable structural design, simple operation and maintenance, and reduces maintenance time and cost. At the same time, it has a variety of installation methods and can be installed in a movable manner to adapt to different working environments, which improves the flexibility and applicability of the equipment.

Strong adaptability

It can handle a variety of materials with different hardness, has low requirements for material humidity (water content ≤8%), and can operate stably in various harsh environments. Therefore, it is widely used in mining, construction, metallurgy, environmental protection and other industries to meet diversified production needs and provide strong support for the development of various industries.

CV215 Impact Crusher Working Principle

The working principle of the CV215 impact crusher is exquisite and efficient. Its core lies in the impact crushing principle of "stone hitting stone". This principle realizes efficient crushing of materials through the mutual collision between the high-speed rotating impeller and the materials. When the materials fall vertically into the crushing chamber through the feed port, they first meet the high-speed rotating impeller. The impeller is driven by an electric motor and rotates at a very high speed, thereby accelerating and throwing the materials out. In this process, the materials gain huge kinetic energy, laying a solid foundation for the subsequent crushing process.

The thrown materials collide with the naturally falling materials or the impact plate in the crushing chamber at a high speed, which is the first crushing. This collision not only causes a strong impact on the materials, but also causes cracks and crushing inside them. The materials after the collision form eddies, and during the return process, they will collide with other materials or the impact plate again for a second time, further crushing. This repeated impact and collision causes the materials to be continuously squeezed, sheared and ground in the crushing chamber until their particle size reaches the required size. During the entire crushing process, the materials undergo multiple impacts and collisions, and their particle size gradually decreases and their shapes gradually become regular. By adjusting the impeller speed and the gap between the impact plates, users can flexibly control the particle size and shape of the output material. This adjustment mechanism ensures that the finished product is cubic and has a low content of needle-like flakes, meeting the production needs of high-standard construction sand and road aggregates.

Finally, the crushed material is smoothly discharged through the discharge port and enters the next processing stage or is collected. CV215 impact crusher has been widely used in many fields such as mining, construction, metallurgy, etc. with its high efficiency, energy saving, environmental protection and intelligence, providing strong support for the development of various industries.

CV215 Impact Crusher Technical Parameters

| Max. feed size | 40.0 mm | Length | 4.35 m |

| Power | 55 kW | Width | 2.16 m |

| Height | 2.00 m | Weight | 6,000 kg |