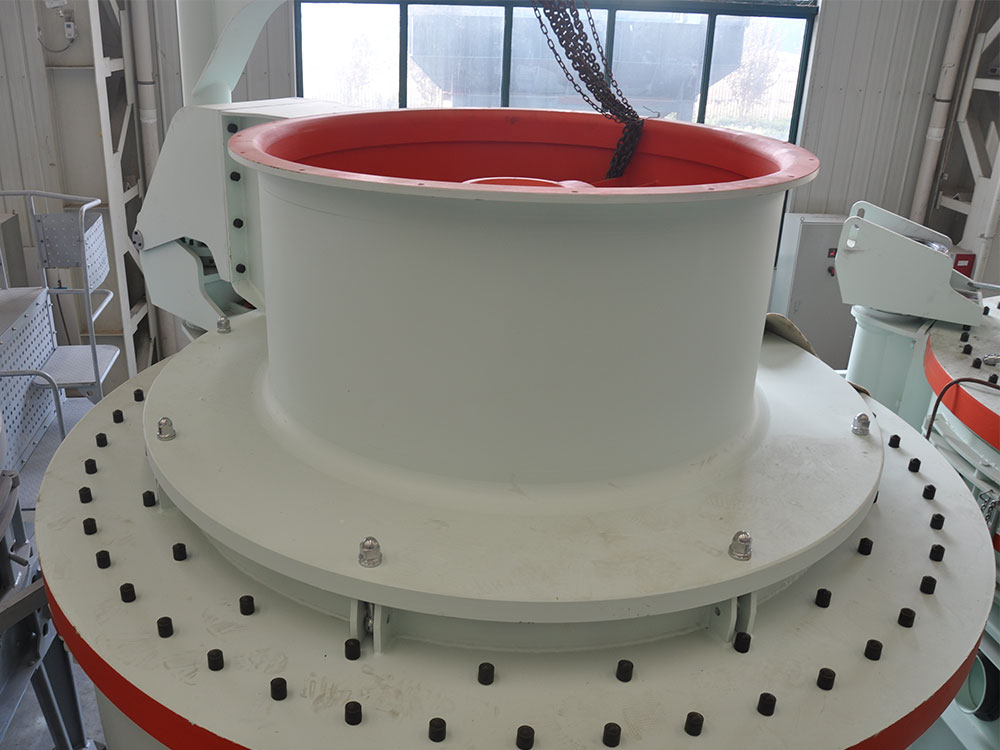

CV217 vertical shaft impact crusher is suitable for crushing ore and construction waste

CV217 Vertical Shaft Impact Crusher (VSI) is an efficient fine crushing and sand making equipment, widely used in construction, mining and sand and gravel production. This series of crushers accelerates the material through the high-speed rotating rotor and collides with the liner in the crushing chamber at high speed, thereby achieving material crushing and sand making. Compared with traditional crushing equipment, CV217 Vertical Shaft Impact Crusher has higher production efficiency and better particle shape control, and is suitable for processing various ores, construction waste and sand and gravel. The working principle of CV217 Vertical Shaft Impact Crusher is based on the impact of the material with the crushing chamber wall and the mutual impact of the materials under the drive of the high-speed rotor. In this way, the material is decomposed into uniform sand particles with excellent particle shape during the crushing process, which is suitable for high-quality construction sand and gravel production. Its main features include high efficiency, low energy consumption, excellent output particle shape, strong production capacity, etc., which can greatly improve the efficiency of sand and gravel production. In addition, the CV217 vertical shaft impact crusher has strong adaptability and can process various ores from medium to high hardness, especially in the production of sandstone, mining, and construction aggregates. The equipment is equipped with a modern automatic control system, which is convenient for operation and adjustment, and has low maintenance costs. Whether in the demanding construction industry or in complex mining applications, the CV217 vertical shaft impact crusher can provide stable and efficient production capacity to meet the different needs of customers.

Advantages of CV217 vertical shaft impact crusher

High efficiency and excellent grain shape

The CV217 vertical shaft impact crusher accelerates the material through the high-speed rotating rotor and impacts the lining plate of the crushing cavity, forming a strong impact force, thereby efficiently breaking the material into uniform sand particles. Its unique crushing method ensures that the sand and gravel products have excellent particle shape and meet the standards of construction, concrete and high-quality sand and gravel. It is especially suitable for applications that require strict particle size distribution.

Low energy consumption and cost savings

Compared with traditional crushing equipment, the CV217 vertical shaft impact crusher has higher working efficiency and can achieve higher production capacity with lower energy consumption. Its advanced design and optimized crushing process reduce energy consumption and help enterprises reduce production costs while improving economic benefits.

Strong adaptability

CV217 vertical shaft impact crusher is suitable for processing a variety of materials, especially for medium-hard to hard materials. Whether it is ore, construction waste or sand and gravel, the equipment can handle it efficiently and is especially suitable for the needs of mining, construction, concrete aggregate and other fields.

Automated control and intelligent management

The CV217 vertical shaft impact crusher is equipped with an advanced automated control system that can monitor the operating status of the equipment in real time and automatically adjust operating parameters to ensure stable operation of the equipment under different loads. In addition, the intelligent management system can predict equipment failures in advance, reduce downtime and improve production efficiency.

Easy maintenance and strong durability

This series of crushers adopts a modular design, and accessories can be easily replaced, which reduces the difficulty of repair and maintenance. The equipment uses highly wear-resistant materials, which extends its service life, reduces the need for frequent replacement of parts, and reduces maintenance costs in long-term operations.

Working Principle of CV217 Vertical Shaft Impact Crusher

The working principle of CV217 Vertical Shaft Impact Crusher (VSI) is based on its unique impact crushing method. It accelerates the material through the high-speed rotating rotor and completes the crushing process by the principle of high-speed collision and rebound. The following is its detailed working principle: First, the material enters the crusher from the feed port and enters the high-speed rotating rotor through the guide pipe. The impeller in the rotor accelerates the material to a high speed of several hundred to thousands of revolutions per hour, giving it huge kinetic energy. Then, these high-speed rotating materials are thrown out through the gap between the rotors and hit the liner or other materials on the wall of the crushing chamber at a very high speed. These impacts and rebounds form multiple crushing, collisions and cutting, so that the material is gradually broken into the required sand particles. In this process, the design of the crushing chamber is very important. It can effectively guide the material and ensure that the material is in full contact with the liner in the crushing chamber, thereby enhancing the crushing efficiency. Through the secondary collision and rebound of the material, the material is finally crushed into a product with a good particle shape and particle size distribution. Different from traditional jaw and cone crushers, the crushing process of CV217 vertical shaft impact crusher relies more on the impact and friction between materials, so it can produce more uniform and high-quality sand particles. This equipment is particularly suitable for producing high-quality construction sand, concrete sand and ore fine crushing. In general, CV217 vertical shaft impact crusher achieves efficient and high-quality crushing effect through its unique rotor acceleration and multiple impact and rebound working mode, which adapts to the processing needs of various hardness materials.

CV217 vertical shaft impact crusher technical parameters

| Output | 50-250t/h | Motor power | 160 kW |

| Feed size | ≤40mm | Machine weight | 15,500kg |

| Discharge size | 0-5mm | Feed opening size | 950x500mm |

CV217 vertical shaft impact crusher case and customer evaluation

Case Overview

The application cases in Mongolia are mainly concentrated in the fields of mining and construction sand and gravel production. Mongolia has a vast territory and a sparse population, and is rich in mineral resources, especially copper, gold, coal, iron ore and other minerals. With the construction of infrastructure and the acceleration of mineral resource development, the demand for high-quality sand and gravel aggregates has gradually increased. In this context, the CV217 vertical shaft impact crusher has become one of the ideal equipment in many projects with its high efficiency and low energy consumption.

Project Background

With the rapid development of the mining industry in Mongolia, the demand for ore processing and construction aggregates has increased significantly. The mining company needs a device that can efficiently produce high-quality sand and gravel, and at the same time has strong adaptability to cope with the processing needs of different types of ores. The original crushing equipment can no longer meet production needs, resulting in frequent equipment failures and high maintenance costs.

Customer Comments

"I am very satisfied with the performance of the CV217 vertical shaft impact crusher. First of all, the equipment has a very high production efficiency and can process a large amount of material in a short time, which greatly improves our production capacity. Secondly, the crushed sand and gravel have a very uniform particle shape, which meets our needs for construction and concrete sand. The particle shape control is very precise and the product quality far exceeds our expectations."

"The automatic control system equipped with CV217 is very convenient, simple and intuitive to operate, which greatly reduces manual intervention and improves the reliability and efficiency of production. Overall, the CV217 vertical shaft impact crusher is a very efficient, energy-saving and durable equipment, which fully meets our high requirements for sand and gravel production."