DM 45 Asphalt Hot Mix Plant,150 ton/hr capacity,Diesel

First of all, the DM 45 crusher adopts an advanced design concept and combines a variety of crushing technologies to effectively handle materials of various hardnesses. The reasonable design of its crushing cavity ensures efficient flow of materials during the crushing process, thus improving crushing efficiency and output. In addition, the equipment is equipped with a powerful motor and a high-strength breaker to ensure stable operation under high load.

Secondly, the DM 45 crusher is also very easy to maintain and operate. Its simple structural design facilitates daily maintenance and reduces equipment downtime. At the same time, the operation interface is friendly and staff can get started quickly, reducing training costs and operational risks. This can significantly improve work efficiency for large-scale engineering projects.The crusher has the advantages of adjustable discharge particle size, low energy consumption and compact structure. It is suitable for a variety of medium-hard and above materials, such as ore and concrete, and greatly improves production efficiency.

DM 45 Asphalt Hot Mix Plant,150 ton/hr capacity,Diesel Working principle

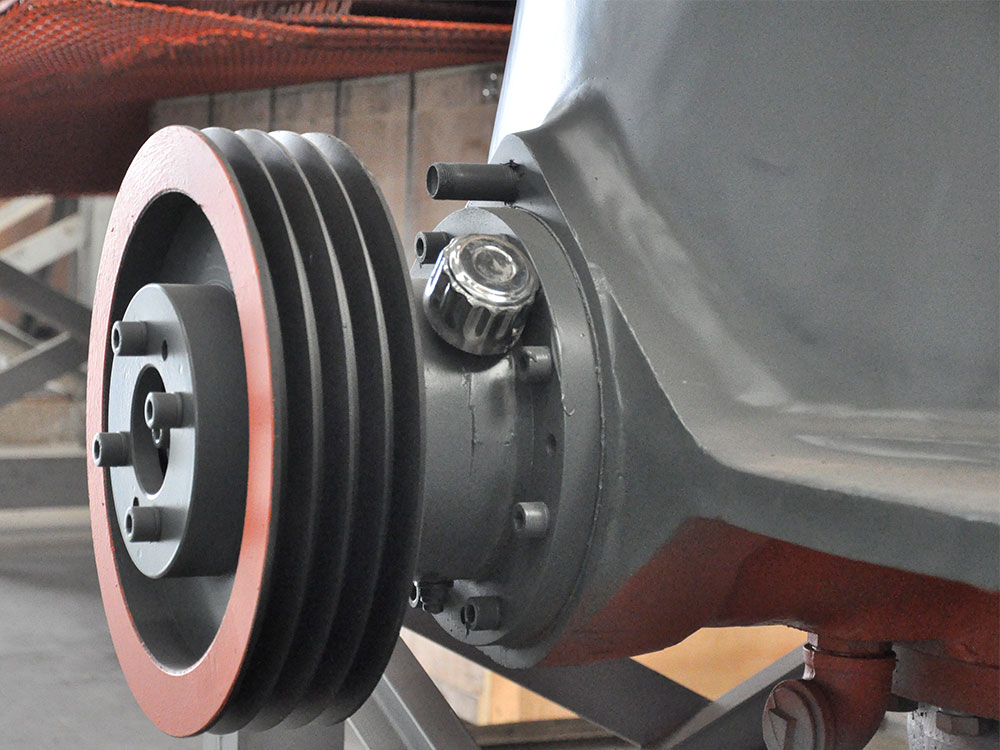

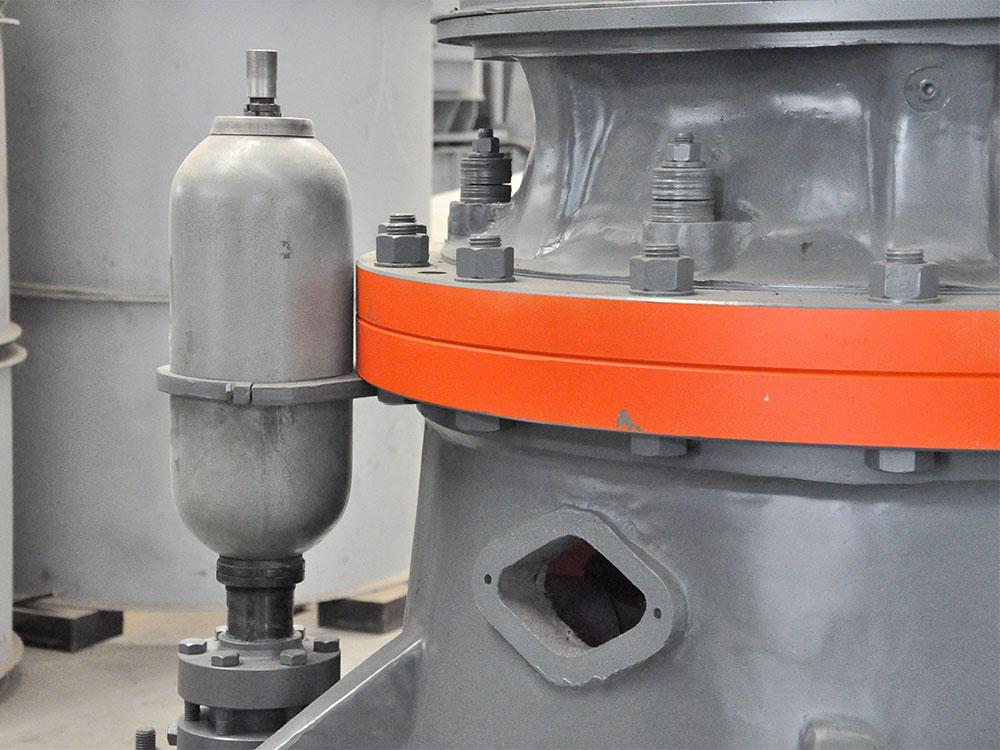

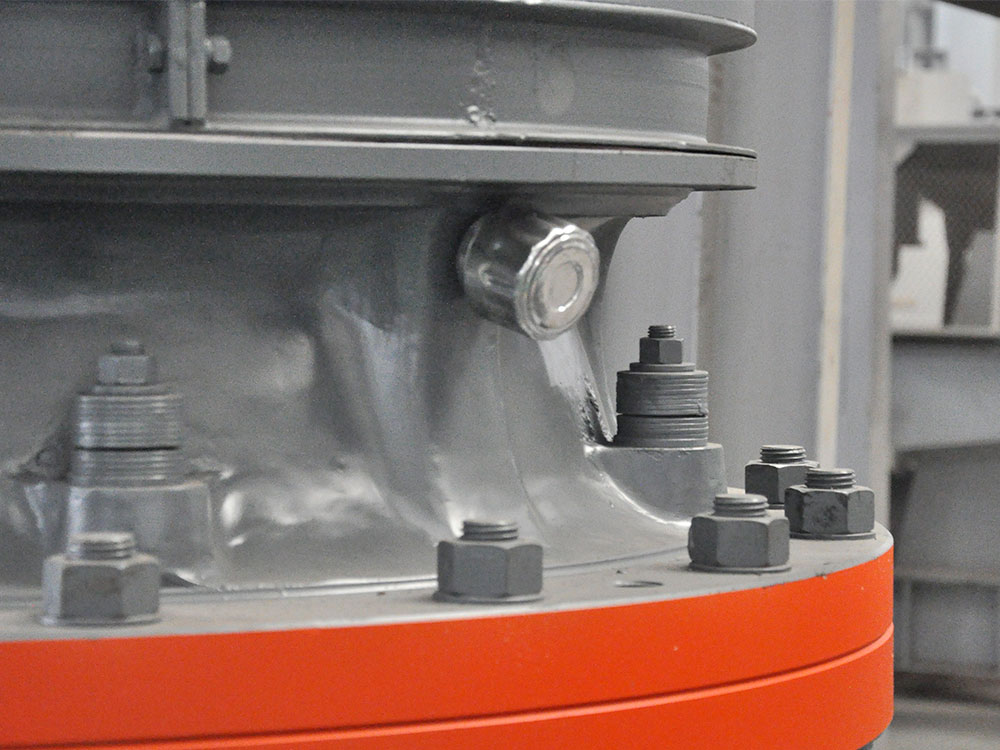

DM 45 crusher is a highly efficient crushing equipment, and its working principle is based on the crushing and crushing of materials. The crusher is mainly composed of a casing, a rotor, a crushing hammer, a screen and other components, and uses mechanical force to crush large pieces of material into smaller particles. When working, the material enters the crusher from the feed port and is sent to the crushing area by gravity and the rotation of the rotor. Under the high-speed rotation of the rotor, the crushing hammer exerts a strong impact force on the material, causing the material to collide and rub with the hammer head and the liner, thereby achieving material crushing. As the material is continuously impacted and squeezed, its particles gradually decrease and are eventually discharged through the screen. The design of the DM 45 crusher focuses on high efficiency and low energy consumption. Its speed and hammer head design are optimized to make energy utilization more efficient. In addition, the crusher's discharge particle size can be achieved by adjusting the aperture of the screen to meet different process requirements.

DM 45 Asphalt Hot Mix Plant,150 ton/hr capacity,Diesel Advantages

High efficiency

The machine's rotor and hammer design have been carefully optimized to achieve higher crushing efficiency. During the operation, the material is impacted by the high-speed rotating hammer head, forming a strong crushing force, so that the raw material is effectively crushed in a short time. Compared with traditional crushing equipment, DM 45 can significantly increase production capacity and reduce production costs per unit product.

The discharge particle size is adjustable.

By adjusting the aperture of the screen, users can flexibly control the particle size of the discharged materials to meet different processes and market needs. This flexibility makes the DM 45 crusher suitable for processing a variety of materials, such as ore, construction waste and concrete, providing customers with greater convenience.

Compact design, small footprint, easy installation and maintenance.

Operators can easily perform daily maintenance and cleaning, which improves the operating efficiency and service life of the equipment. In addition, the sturdy casing and wear-resistant hammer material ensure the stable operation of the equipment under harsh conditions and reduce the failure rate.

Excellent performance in terms of energy consumption

The use of advanced motor drive system optimizes energy efficiency and reduces energy consumption. This not only helps companies save operating costs, but also conforms to modern environmental protection concepts and reduces the impact on the environment during the production process.

Wide adaptability

It is not only suitable for crushing medium-hard and hard materials, but also can handle many types of materials to meet the needs of different industries. Whether in the mining, building materials or metallurgical industries, DM 45 can provide excellent crushing effects and is widely used in production lines.

DM 45 Asphalt Hot Mix Plant,150 ton/hr capacity,Diesel Cases and Technical parameters

| Output | 20-80t/h | Machine weight | 8-15t |

| Input size | 300-500mm | Motor power | 55kw |

| Output size | 10-50mm | Power requirement | 37-75kw |

DM 45 Asphalt Hot Mix Plant,150 ton/hr capacity,Diesel Cases and customer testimonials

In Canada, the application cases of DM 45 crusher reflect its excellent performance and reliability. A large mining company introduced the DM 45 crusher in its gold mining project to improve ore processing efficiency. In the early stages of the project, the company faced problems of insufficient material handling capacity and high energy consumption, so it chose the DM 45 as a solution. After installation and commissioning, the performance of the DM 45 crusher exceeded the customer’s expectations. Production capacity has increased by approximately 30%, significantly reducing unit product costs. In addition, the equipment performs well when processing hard ores, and the discharged particle size is uniform, which meets the requirements of subsequent processes. Through optimized design, the crusher also has significant improvements in energy consumption, helping the company reduce overall operating costs.

The project manager said: "After the introduction of the DM 45 crusher, our production efficiency has been significantly improved. The stability and low failure rate of the equipment have made our production process smoother. Especially in the face of high-load working environments, the DM 45 has always Excellent performance with almost no downtime. ”

The operator said: "The DM 45 has a reasonable structural design, which makes daily inspection and maintenance work simple. This not only reduces maintenance time, but also improves the overall production efficiency."