Dual-mode “Stone-on-Stone” and “Stone-on-Iron”! The VSI5X7615 sand maker adapts flexibly.

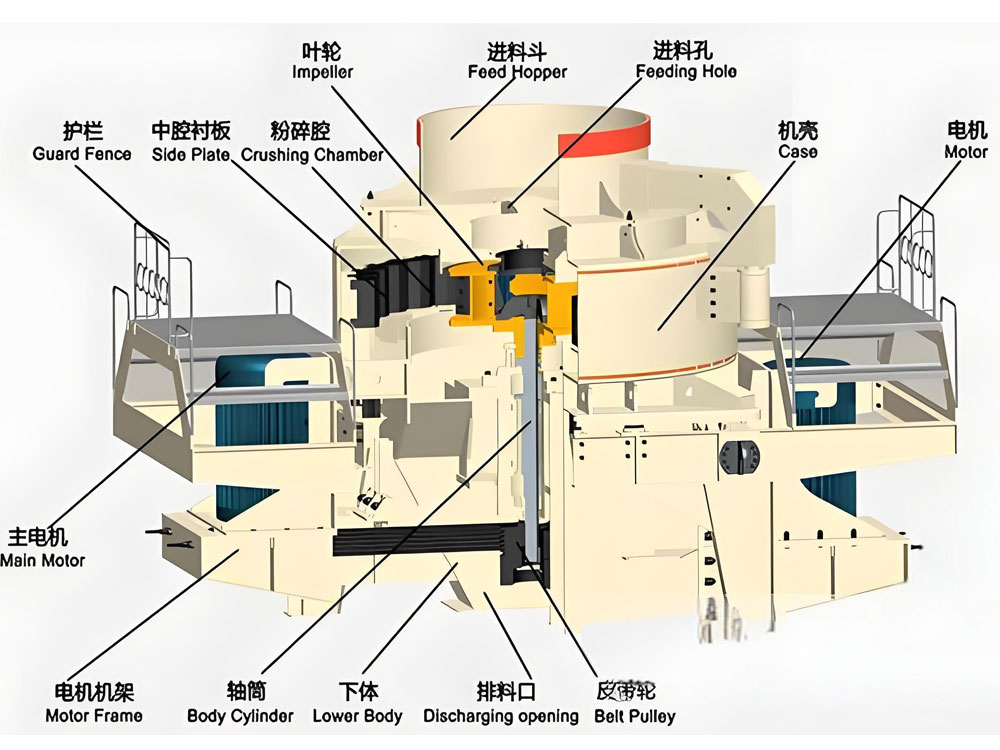

The VSI5X7615 sand-making machine is a fifth-generation vertical shaft impact crusher specifically designed for fine crushing and shaping of medium-to-high hardness materials such as granite, basalt, and iron ore. Its core structure features a deep-cavity rotor and modular discharge head design, achieving a 30% higher throughput than traditional equipment. Maximum feed size reaches 35mm (soft materials) or 30mm (hard materials). Equipped with dual motors rated at 110-150kW, it delivers processing capacities ranging from 150-280t/h (both cascade and center-feed modes). The equipment features freely switchable “stone-on-stone” and “stone-on-iron” dual crushing modes. The finished sand exhibits cubic particle shape, uniform gradation, and adjustable fineness modulus, fully meeting construction sand standards.

This model employs an oil-lubrication system and hydraulic cover-opening device, enabling constant-temperature bearing operation and rapid maintenance. Wear-resistant component lifespan is extended by over 48%. Operating principle: Material enters the high-speed rotating rotor (1700-1900 rpm) through the central feed port, accelerates, and is ejected. It undergoes multiple impacts with rebounding material within the vortex chamber, forming a continuous material curtain before discharge through the lower outlet. Technical highlights include digital precision machining control, a dual-pump complementary oil supply safety protection system, and winter motor heating start-up functionality, ensuring stable operation in environments ranging from -30°C to 40°C. With dimensions of 4100×2330×2300mm and a total weight of 8.6 tons, it is suitable for sand and gravel yards, concrete mixing plants, and large-scale infrastructure projects.

The VSI5X7615 sand maker's technical advantages primarily lie in its highly efficient, energy-saving crushing system and intelligent design. Adopting a German deep-cavity rotor structure, it optimizes the throwing head angle and flow channel design to increase material acceleration efficiency by 40% and reduce energy consumption per unit by 15%. Its innovative dual-mode switching mechanism—“stone-on-stone” and “stone-on-iron”—automatically selects the optimal crushing path based on material hardness. For high-hardness materials like granite, the “stone-on-iron” mode enhances impact force. When processing medium-hardness materials such as river pebbles, it switches to “stone-on-stone” mode to reduce wear part consumption. The hydraulic lubrication system incorporates a dual-pump complementary oil supply device. Should the main pump fail, the backup pump automatically takes over within 0.5 seconds. Combined with a water-cooled temperature reduction module, this ensures bearing temperatures remain stable below 60°C. The digital control system continuously monitors rotor vibration values (≤4.5mm/s) and current fluctuations (±5%). Upon detecting abnormal parameters, it automatically adjusts feed rate and triggers an alarm, preventing machine stalling risks. A specially configured 2kW oil tank heater for winter operation can raise lubricant temperature above 15°C within 10 minutes at -25°C environments, ensuring reliable low-temperature startup.

As the core equipment in modern sand and gravel production lines, the VSI5X7615 sand maker demonstrates extensive application value across multiple industrial sectors through its outstanding crushing performance and intelligent design. In the building materials industry, it processes hard rocks like granite and basalt into high-quality manufactured sand ranging from 0-5mm. The crushed value of the finished sand is below 12%, fully meeting the aggregate requirements for C50 and higher concrete. In mining operations, its 150-280 t/h processing capacity efficiently crushes metal ores like iron and copper. By adjusting rotor speed (1700-1900 r/min), it achieves precise 3-8mm particle size control, supplying uniform feedstock for mineral processing. In infrastructure projects, the cubic sand and gravel produced by this equipment exhibit sharp edges when used for high-speed rail track slab laying. This enhances cement bonding strength by 18% and significantly reduces ballast breakage rates. For environmental sustainability, this model's oil-based lubrication system reduces grease consumption by 80% compared to traditional grease lubrication. Combined with its enclosed dust collection design, dust emission levels remain below 20mg/m³, meeting green mining standards. Additionally, its modular structure enables rapid relocation for on-site operations. A single unit can complete the entire process from crushing and shaping to sand production, making it particularly suitable for dispersed projects like hydroelectric dams and municipal road construction.

Dual-mode “Stone-on-Stone” and “Stone-on-Iron”! The VSI5X7615 sand maker adapts flexibly. Applications

1. Aggregate Production

This equipment serves as the core component of manufactured sand production lines, processing hard rocks such as granite and basalt into high-quality manufactured sand with particle sizes ranging from 0 to 5 mm. The crushed value of the finished sand is below 12%, fully meeting the aggregate requirements for concrete grades C50 and above. Its cubic particle shape enhances the bond strength between sand/gravel and cement by 18%, significantly reducing ballast breakage rates. It is widely used in high-rise construction, municipal projects, and bridge engineering.

2. Mining and Metal Ore Processing

In the metal mining sector, the VSI5X7615 sand maker efficiently crushes iron ore, copper ore, and other slag. By adjusting the rotor speed (1700-1900 r/min), it achieves precise particle size control between 3-8mm, supplying uniform raw materials for mineral processing. Its wear parts, manufactured from American materials, extend service life by 48%, making it particularly suitable for fine crushing of highly abrasive materials.

3. Transportation Infrastructure Projects

This equipment supplies premium aggregate for high-speed rail and highway projects. Its cubical sand and gravel, featuring sharp edges and corners, significantly enhances ballast stability during track slab installation. In large-scale infrastructure projects, its modular design enables rapid relocation, with a single unit capable of completing the entire crushing and shaping process.

4. Hydropower and Environmental Projects

For hydropower dam construction, the VSI5X7615 sand maker processes river pebbles and weathered sand into uniformly graded finished sand meeting strength requirements for mass concrete. Its enclosed dust collection system maintains emissions below 20mg/m³, complying with green mining standards.

5. Concrete Batching Plants and Dry-Mix Mortar

The machine-made sand produced by this equipment features adjustable fineness modulus, precisely matching the mix design requirements for different grades of concrete. In dry-mix mortar production, its low stone powder content (intelligently controllable) reduces additive usage and lowers production costs.

6. Metallurgical and Industrial Waste Processing

This equipment crushes industrial waste such as steel slag and construction debris, enabling resource recycling. Its “stone-on-iron” mode boosts crushing efficiency by 30% for high-hardness materials like metallurgical slag, while the thin-oil lubrication system reduces grease consumption by 80%, meeting environmental requirements.

Dual-mode “Stone-on-Stone” and “Stone-on-Iron”! The VSI5X7615 sand maker adapts flexibly. Advantages

The VSI5X7615 sand maker, as a fifth-generation vertical shaft impact crusher, demonstrates significant technical advantages in construction aggregate production. Featuring a German deep-cavity rotor structure, it optimizes the throwing head angle and flow channel design to increase material acceleration efficiency by 40% while reducing energy consumption per unit by 15%. The equipment's innovative dual-mode switching mechanism—switching between “stone-on-stone” and “stone-on-iron” modes—automatically selects the optimal crushing path based on material hardness. When processing high-hardness materials like granite, the “stone-on-iron” mode enhances impact force. For medium-hardness materials such as river pebbles, it switches to “stone-on-stone” mode to reduce wear part consumption. The crushed sand's fineness modulus remains below 12%, fully meeting aggregate standards for C50+ concrete. The hydraulic lubrication system incorporates dual complementary oil pumps; if the main pump fails, the backup automatically takes over within 0.5 seconds. Combined with a water-cooled temperature reduction module, this ensures bearing temperatures remain below 60°C, enabling stable operation in environments ranging from -25°C to 40°C. The digital control system continuously monitors rotor vibration (≤4.5mm/s) and current fluctuations (±5%). Upon detecting parameter anomalies, it automatically adjusts feed rate and triggers alarms to prevent stalling. The winter-ready 2kW tank heater rapidly warms lubricating oil to above 15°C within 10 minutes, ensuring reliable cold-start performance. Its modular structure supports rapid relocation for on-site operations. A single unit completes the entire process from crushing and shaping to sand production, making it particularly suitable for decentralized engineering projects.

The VSI5X7615 sand maker's intelligent and eco-friendly features further enhance its competitive edge. Equipped with a digital precision control system, it employs high-accuracy sensors to monitor rotor vibration (≤4.5mm/s) and current fluctuations (±5%) in real time. Upon detecting parameter anomalies, it automatically adjusts feed rate and triggers an alarm, effectively preventing equipment overload risks. Its hydraulic lubrication system innovatively employs a dual-pump complementary oil supply design. Should the main pump fail, the backup pump seamlessly takes over within 0.5 seconds. Combined with a water-cooled temperature reduction module, it precisely controls bearing temperatures below 60°C, ensuring stable operation in extreme environments ranging from -25°C to 40°C. A specially configured 2kW oil tank heater for winter operation can raise lubricant temperature to above 15°C within 10 minutes, significantly enhancing operational reliability in cold regions. For environmental compliance, this model employs an enclosed dust collection system to control dust emissions below 20mg/m³, meeting green mining standards. Its thin-oil lubrication system reduces grease consumption by 80% compared to traditional grease lubrication, while the self-circulating air system effectively minimizes noise pollution. Its modular structure enables rapid relocation for on-site operations. A single unit handles the entire process from crushing and shaping to sand production, making it particularly suitable for dispersed projects like hydroelectric dams and municipal roads. This significantly reduces contractors' equipment investment and operational costs.

Dual-mode “Stone-on-Stone” and “Stone-on-Iron”! The VSI5X7615 sand maker adapts flexibly. Works Principle

The VSI5X7615 sand maker is a high-efficiency sand-making equipment utilizing the vertical shaft impact crushing principle. Its core working mechanism is based on a dual-mode crushing system combining “stone-on-stone” and “stone-on-iron” processes. Material enters the high-speed rotating rotor (1700-1900 r/min) through the central feed inlet. Accelerated by centrifugal force to dozens of times gravitational acceleration, it is ejected to form a continuous impact curtain with rebounding material within the vortex chamber. This equipment achieves optimized crushing paths for different materials by switching between cascade and central feed modes. Material enters the distributor via the feed hopper and splits into two streams: 70% enters the high-speed rotating centrifugal wheel, while 30% forms a circular cascade flow. Material within the centrifugal wheel accelerates to 60-75 m/s within 0.1 seconds, initiating the first impact with the cascade flow. The high-velocity ejected material undergoes a secondary impact against either the vortex chamber lining (stone-on-stone mode) or metal impact plates (stone-on-iron mode), creating a triple crushing effect: “material-material-lining.” After 2-4 impacts within the chamber, particle size reduces from 35mm to 0-5mm. Crushed material discharges through the lower outlet, undergoes vibrating screen classification, with qualified products entering the finished goods area while oversize material recirculates for reprocessing.

Dual-mode “Stone-on-Stone” and “Stone-on-Iron”! The VSI5X7615 sand maker adapts flexibly. Technical Parameters

| soft material | 35mm | Hard material | 30mm |

| Waterfall and Center Feed | 150-280 t/h | Center-fed | 70-140 t/h |

| Spindle speed | 1700-1900 r/min | Power | 75×2 kw |