Efficient and intelligent CV218, crushing more easily

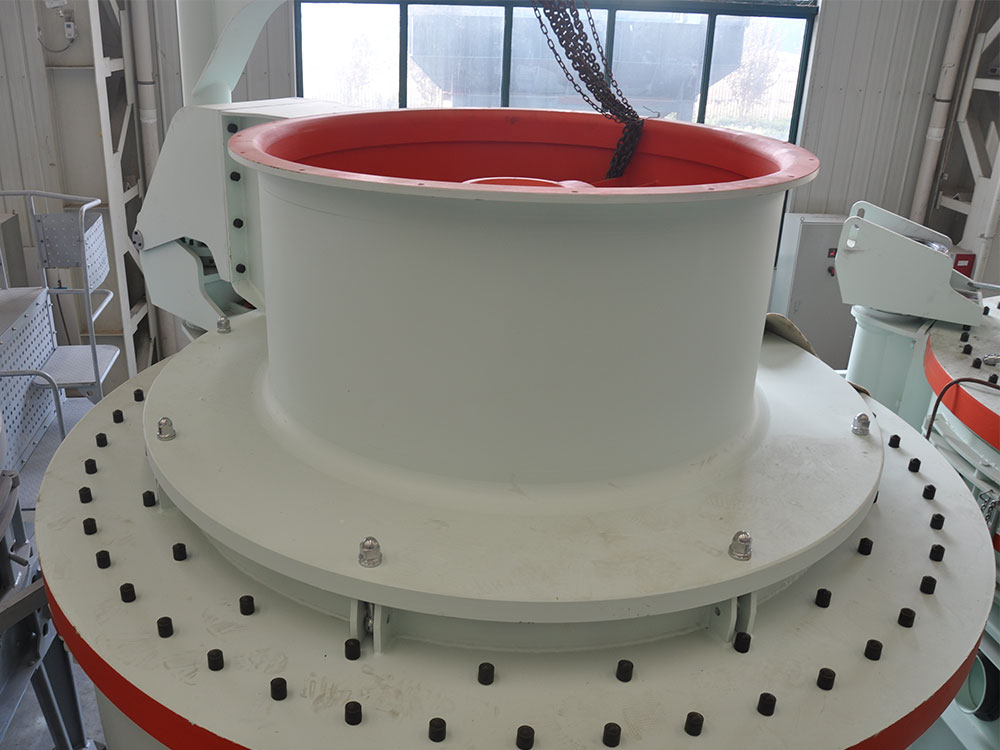

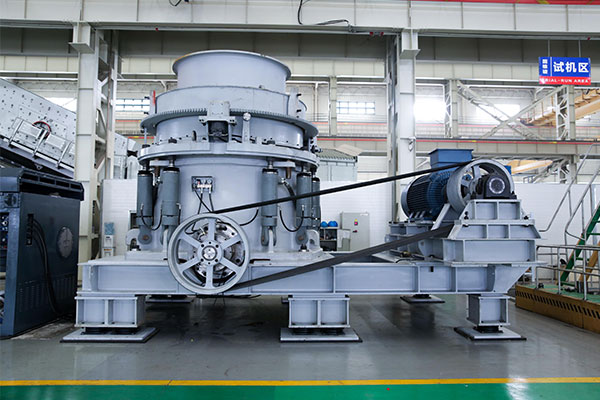

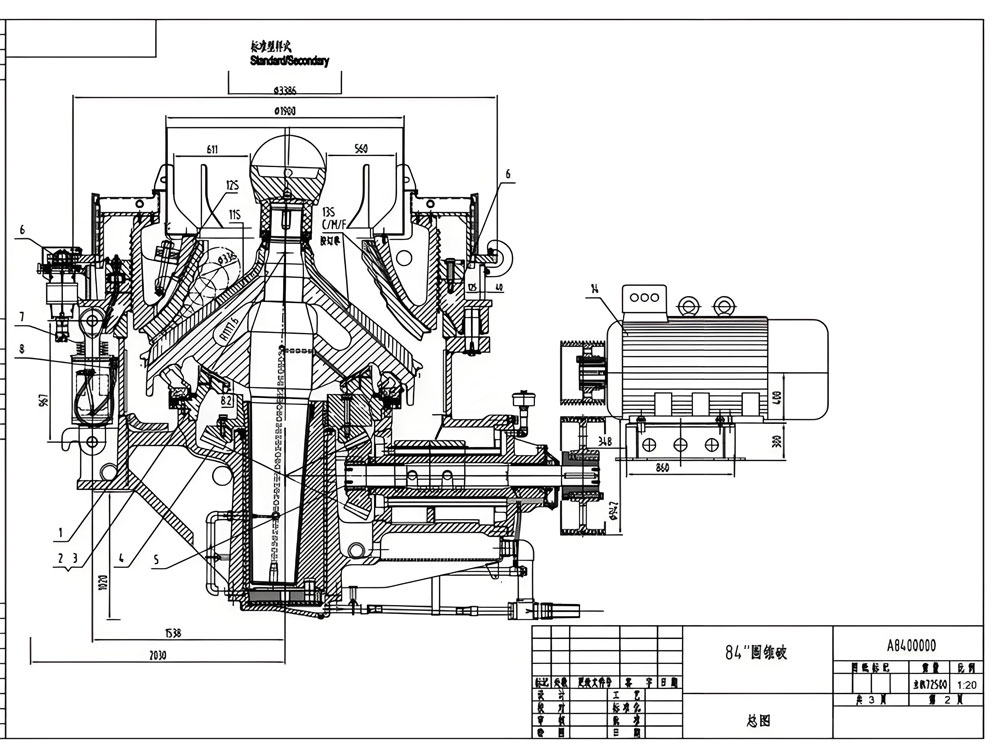

CV218 Cone Crusher adopts advanced modular design concept, which makes its overall structure more compact and reasonable. The main part of the machine is mainly composed of key components such as frame, dynamic cone assembly, fixed cone assembly, hydraulic system, transmission device, etc. Each component is carefully designed and strictly manufactured to ensure the overall performance and stability of the machine.

Among them, the dynamic cone assembly is one of the core components of CV218 Cone Crusher. It is driven by the eccentric sleeve to realise the rotary pendulum movement, forming a progressive crushing chamber with the fixed cone. The design of this crushing chamber is very clever, which enables the material to be crushed into smaller particles while being squeezed and sheared. In addition, the dynamic cone assembly also integrates a variety of functions such as discharge opening adjustment, overload protection and cavity clearing, making the equipment more intelligent, safe and efficient during operation.

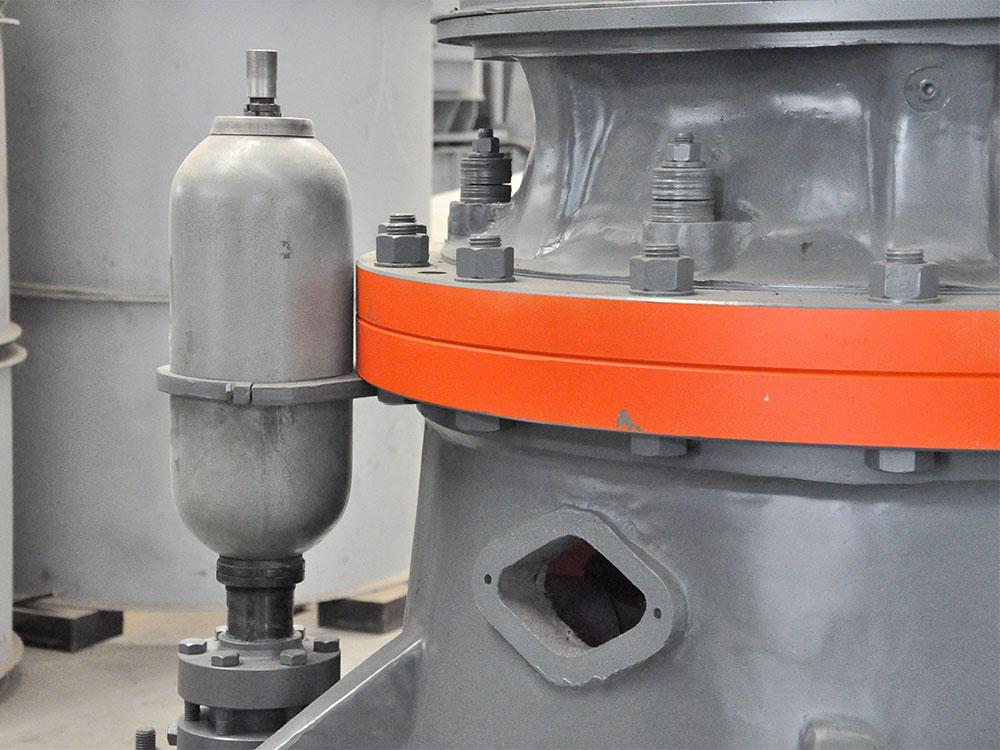

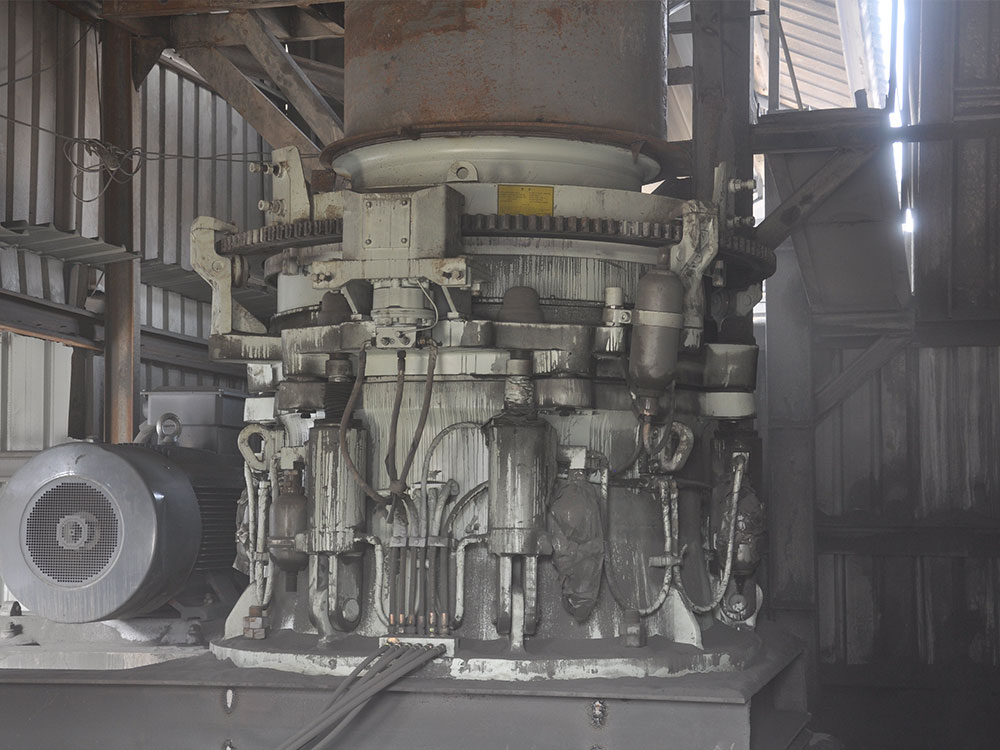

As one of the power sources of CV218 Cone Crusher, the hydraulic system plays a crucial role. It not only provides stable power output for the equipment, but also can be precisely adjusted and controlled according to the actual demand. Through the adjustment of the hydraulic system, users can easily adjust the width of the discharge opening, thus controlling the particle size of the finished material. Meanwhile, the hydraulic system also has an overload protection function, when the equipment is subjected to excessive load, it can automatically stop and issue an alarm to avoid equipment damage and accidents.

The transmission device is another key component of CV218 Cone Crusher. It adopts an electric motor to drive the eccentric sleeve through the bevel gear to drive the cone to complete the continuous crushing action. This transmission method is not only simple and compact, but also has high transmission efficiency and low noise. In actual operation, the transmission device can ensure the high-speed and stable operation of the equipment, providing a strong guarantee for efficient crushing.

The capacity of CV218 Cone Crusher is up to 200 tonnes/hour, and the range of discharge size is between 12-60mm. Meanwhile, it supports multi-stage crushing mode with a crushing ratio of up to 5:1, which can ensure the uniformity of the finished particles. These excellent performance parameters make the CV218 Cone Crusher have a wide range of application prospects in the fields of mining, sand and gravel aggregate production and industrial solid waste treatment.

Efficient and intelligent CV218, crushing more easily Applications

In the tough environment of mining, the CV218 Cone Crusher stands out with its outstanding performance, making it an ideal choice for secondary or tertiary crushing of iron ore, copper ore, granite and other high hardness materials. Its rugged design, coupled with its highly efficient crushing capacity, ensures continuous and stable operation even under harsh mining conditions. Intelligent control technology further enhances the crushing efficiency of the equipment, resulting in finer crushing of ores and significantly improved product quality. This not only directly improves the production efficiency of the mine, but also effectively reduces the operating costs by optimising the crushing process, bringing considerable economic benefits to the mining enterprises.

In the sand and gravel aggregate production line, CV218 cone crusher and jaw crusher work hand in hand to form the core strength of the middle and fine crushing process. After the jaw crusher completes the initial crushing of the material, the CV218 cone crusher takes over the baton and further crushes the material to the ideal particle size. Its precise crushing ability makes the sand and gravel aggregate produced with uniform particle size and regular shape, which fully meets the demand for high-quality aggregates for construction, roads, bridges and other infrastructures. This advantage makes the CV218 Cone Crusher occupy an important position in the field of sand and gravel aggregate production, and the market prospect is bright.

In the field of industrial solid waste treatment, CV218 cone crusher also shows its extraordinary value. Facing metallurgical slag, construction waste and other renewable resources, CV218 cone crusher, with its powerful crushing capacity, transforms these wastes into valuable raw materials or reused products. This transformation not only effectively reduces environmental pollution and resource waste, but also opens up new profit growth points for enterprises. With the continuous promotion of national policies on environmental protection and resource recycling, CV218 cone crusher will be more widely used in the field of industrial solid waste treatment, and become an important force to promote green and sustainable development.

Efficient and intelligent CV218, crushing more easily Advantages

CV218 Cone Crusher excels in high efficiency and energy saving. It adopts the advanced laminated crushing principle, which effectively reduces energy consumption by means of synergistic extrusion of multiple particles. Compared with traditional crushing equipment, the unit power consumption of CV218 Cone Crusher is reduced by 15%. This remarkable energy saving effect enables the equipment to significantly reduce energy consumption during operation, saving production costs for enterprises, and at the same time helping to reduce carbon emissions and protect the environment.

In terms of intelligent control, the CV218 cone crusher is built-in with an advanced PLC system. This system not only supports remote monitoring, allowing operators to understand the operating status of the equipment in real time, but also has automatic diagnosis and fault alarm functions. When equipment failure occurs, the PLC system can quickly identify and issue an alarm, which greatly reduces the need for manual intervention and improves the operational efficiency and stability of the equipment. This intelligent control not only simplifies the operation process, but also improves the reliability and safety of the equipment.

Convenient maintenance is also a highlight of the CV218 Cone Crusher. The equipment adopts a modular component design, which greatly simplifies the disassembly and assembly process and enables maintenance personnel to replace or repair components more quickly and easily. In addition, the CV218 Cone Crusher is equipped with a hydraulic cavity cleaning system, which can quickly clean the material in the crushing cavity in a short period of time, shortening the downtime by 30%, thus improving the utilisation and productivity of the machine.

In terms of stability and durability, the CV218 Cone Crusher also excels. The key parts of the machine are made of high manganese steel casting, which has high hardness and abrasion resistance, and is able to withstand the strong impact and abrasion of the material in the crushing process. At the same time, the equipment is also equipped with a hydraulic overload protection device, when the equipment is subjected to excessive load, the protection device can be quickly activated to avoid damage to the equipment, effectively extending the service life of the equipment. These designs enable the CV218 Cone Crusher to maintain stable and reliable operation even in harsh working environments.

Efficient and intelligent CV218, crushing more easily Working Principle

The material falls steadily into the crushing chamber from the top inlet of CV218 Cone Crusher and starts its crushing journey. In this process, the moving cone is driven by the strong eccentric sleeve and undergoes cyclic rotary oscillation movement. This movement and the fixed cone form a clever extrusion and splitting effect, so that the material in the cavity is constantly subjected to extrusion, splitting and bending of a variety of crushing force, so as to achieve continuous and efficient crushing.

After this series of crushing process, the materials are gradually finely crushed into the required particle size. Subsequently, these crushed materials are naturally discharged from the bottom discharge port under the action of self-weight, completing the whole crushing process. It is worth noting that for those particles that do not reach the required size, they will continue to be crushed in the crushing chamber in a cycle until they meet the requirements. This design ensures that the CV218 Cone Crusher is able to produce finished materials of uniform size and consistent quality.

In order to ensure a stable material size, the CV218 Cone Crusher is also equipped with a sophisticated hydraulic cylinder system. This system can adjust the position of the moving cone in real time to precisely control the size of the discharge opening. The CV218 Cone Crusher is also equipped with excellent self-protection ability. When encountering unbreakable foreign objects, the hydraulic system will automatically release the pressure, so that the moving cone will quickly retreat, thus avoiding the equipment from being damaged by strong impact. This intelligent protection mechanism greatly extends the service life of the equipment and reduces the user's maintenance cost.

In terms of drive, the motor precisely drives the eccentric sleeve to rotate through the bevel gear set. This rotary motion is cleverly transformed into a compound oscillation of the moving cone, i.e. a combination of rotary oscillation and rotation. This unique movement not only improves the crushing efficiency, but also makes the equipment more stable and reliable during operation.

Efficient and intelligent CV218, crushing more easily Technical Parameters

| power | 90 kW | Capacity | 200 t/h |

| Max. feed size | 267.0 mm | range | 13.0 - 35.0 mm |

| Weight | 7,188 kg |