Fully Hydraulic Control HPT100 Cone Crusher: Stable, Reliable, and Hassle-Free!

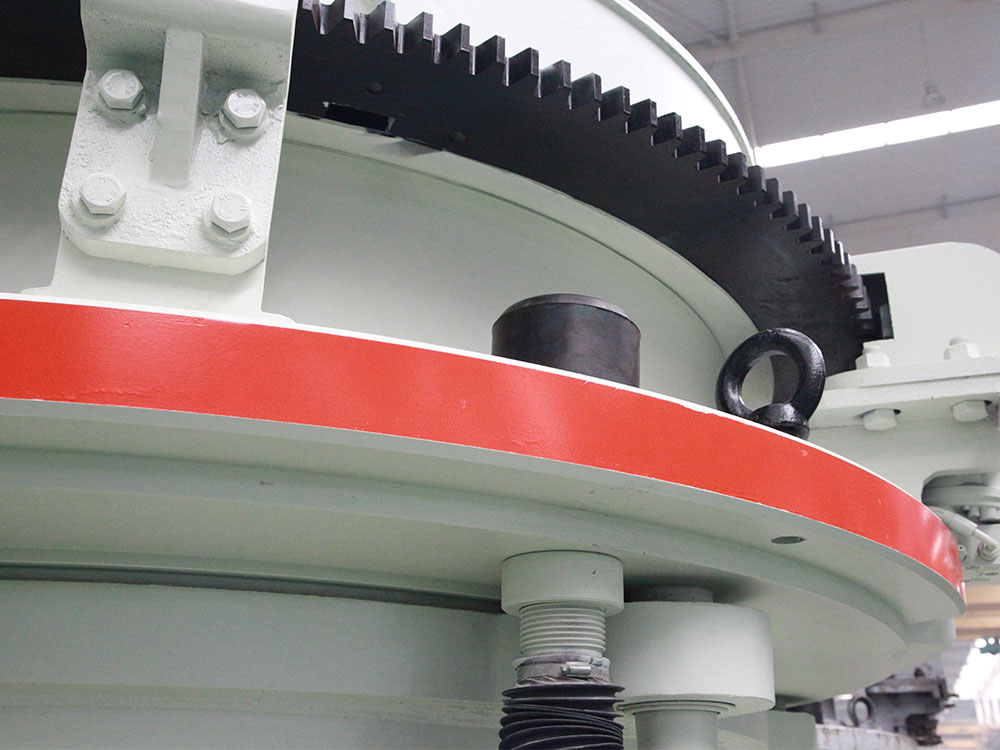

The HPT Hydraulic Cone Crusher is a high-efficiency medium-fine crushing equipment utilizing the laminar crushing principle, specifically designed for secondary/tertiary crushing operations in metal mining, construction aggregates, and similar industries. Its core structure comprises a fixed cone assembly, a moving cone assembly, multiple hydraulic cylinders, and an intelligent control system. Through a unique design featuring a fixed main shaft and rotating eccentric sleeve, it achieves continuous compression and laminar crushing of materials within the crushing chamber. This equipment achieves a maximum processing capacity of 1200 tons per hour, handling medium-hard materials like iron ore and granite. In iron ore fine crushing projects, its output reaches 1.9 times that of traditional equipment. Its modular design incorporates 10-16 integrated hydraulic cylinders, featuring both iron overload protection and automatic discharge opening adjustment. Equipped with a Siemens PLC control system, it enables fully automated operation and real-time monitoring. As a technological upgrade to spring cone crushers, the HPT series significantly enhances crushing efficiency and product quality by optimizing the moving cone trajectory and crushing chamber configuration. The HPT hydraulic cone crusher operates on the principle of laminar crushing, centered on the rotating swing motion of the moving cone driven by an eccentric sleeve. The motor drives the eccentric sleeve via a transmission shaft, forcing the moving cone to swing along the crushing chamber wall. Material undergoes multidirectional compression, bending, and shearing between the moving and fixed cones. This unique laminated crushing design shifts the primary crushing action between particles rather than direct liner contact, reducing energy consumption and over-crushing. The hydraulic system achieves three functions through multiple cylinders: dynamic adjustment of the discharge opening size (with ±1mm precision), iron overload protection (with adjustable pressure thresholds), and automatic crushing chamber cleaning. When non-crushable objects enter the chamber, the hydraulic system triggers pressure relief protection. The movable cone instantly descends to widen the discharge opening for ejecting foreign objects, then automatically resets. The intelligent control system continuously monitors main shaft speed, oil pressure, and vibration data. Through PLC algorithms, it optimizes the matching of eccentricity and swing frequency, boosting crushing efficiency by over 30%. This synergy of mechanical, hydraulic, and electrical systems enables the equipment to maintain a wide processing capacity range of 45-1200 tons/hour while reducing energy consumption by 43% compared to traditional models. The technical advantages of the HPT hydraulic cone crusher manifest in three dimensions: First, its multi-cylinder hydraulic system synergizes with the laminating crushing chamber to elevate the cubic content of finished aggregates to over 90% while reducing needle- and flake-shaped particles by 50%, significantly enhancing concrete aggregate quality. Second, the intelligent control system, powered by Siemens PLC, enables automatic discharge opening adjustment (±0.5mm precision) and overload protection. Combined with ABB low-voltage components, it reduces failure rates by 60% and extends maintenance intervals to 2000 hours. Finally, the modular design permits side-access replacement of the moving cone assembly. A triple-path lubrication system ensures stable operation of critical components like the eccentric sleeve and spherical bearings across temperatures from -30°C to 50°C, extending the machine's service life by 40% compared to conventional models. This equipment holds ISO9001 certification. Its eco-friendly mining characteristics have been validated in projects like Hubei pebble sand production, achieving a capacity of 200 tons/hour with dust emissions below 10mg/m³.

Fully Hydraulic Control HPT100 Cone Crusher: Stable, Reliable, and Hassle-Free! Applications

As core crushing equipment in the modern mining and building materials industries, the HPT hydraulic cone crusher, with its efficient laminated crushing technology and intelligent control system, is widely used in metal mining, construction sand and gravel processing, metallurgy, and chemical industries. In the metal mining sector, this equipment is primarily used for secondary and tertiary crushing of medium-hard materials such as iron ore, copper ore, and gold ore. Its multi-cylinder hydraulic system provides iron overload protection and precise discharge adjustment, significantly improving process efficiency for "more crushing, less grinding." For example, at the Jinniu Iron Ore Project in Luanping, Hebei Province, the HPT series equipment increased production capacity by 30%, reduced needle-like and flake-like material by 20%-30%, and reduced specific power consumption by 15%-30%. The construction sand and gravel industry utilizes its optimized crushing chamber to produce high-quality aggregates. The HPT500 model, adopted in a granite processing line in Macheng, Hubei Province, significantly improved the uniformity of the finished product, meeting the high cubic particle size requirements of concrete mixing plants. Furthermore, in the metallurgical and chemical industries, this equipment can also process materials such as lead-zinc ore and quartz stone. Its laminated crushing technology effectively reduces liner wear and extends equipment life. The HPT series, with its PLC intelligent control system enabling remote monitoring and automated adjustments, has become an indispensable, efficient crushing solution for green mining development.

In metal mining applications, the HPT hydraulic cone crusher, with its multi-cylinder hydraulic system and laminated crushing technology, significantly improves the fine crushing efficiency of hard rocks such as iron ore and copper ore. For example, at the Jinniu Iron Mine in Luanping, Hebei Province, the use of the HPY800 model increased crushing capacity by 30%, reduced the needle-like flake content in the finished product by 20%-30%, and reduced unit energy consumption by 15%-30%. This equipment features a fixed spindle and high-speed design, along with an adjustable 13-38mm discharge opening, for precise control of product particle size, meeting the demanding requirements of metal mines for high production capacity and low recovery rates. At the Dandong Gold Mine project in Liaoning Province, the HPT300F model serves as the core equipment for secondary and tertiary crushing, working in conjunction with a jaw crusher to perform multi-stage crushing, ultimately producing a uniformly sized, qualified material. The customer praised its stable and reliable quality, and its fully met production requirements. In addition, its hydraulic protection system automatically handles overload faults, reducing downtime. Siemens motors and PLC control systems enable intelligent operation and management, driving metal mines towards efficiency and automation.

In the construction sand and gravel processing sector, the HPT hydraulic cone crusher, with its laminated crushing technology and intelligent control system, has become a core piece of equipment for producing high-quality aggregates. The Hubei Macheng granite processing line uses the HPT500 model for medium and fine crushing. Its optimized multi-cavity design significantly improves the uniformity of the finished product's particle shape, significantly reducing the amount of needle-like flakes in concrete aggregate and meeting high-standard construction sand requirements. The Harbin Bayan basalt gravel production line uses the HPT500 model as the secondary crushing equipment, coupled with a vibrating screening system, to achieve an efficient production capacity of 350 tons/hour. The finished product particle size remains stable within the 0-35mm range. Customer feedback indicates that it offers "high output, low energy consumption, and significant production cost advantages." This equipment uses a PLC integrated control system to monitor operating parameters in real time, streamlining operations. A hydraulic lubrication system ensures stable operation of key components, making it particularly suitable for applications with stringent requirements for particle shape and production capacity, such as sand and gravel yards and concrete mixing plants. In the Hubei Xiangyang cobblestone sand-making project, the HPT model's efficient crushing capacity and low-maintenance features further demonstrated its wide applicability in the construction sand and gravel industry.

In the metallurgical and chemical industries, the HPT hydraulic cone crusher, with its high wear resistance and precise particle size control, has become a key piece of equipment for processing medium-hardness materials such as lead-zinc ore and quartz stone. The Yunnan Funing lead-zinc mine project utilizes a dual HPT300C and HPT300F configuration. This configuration utilizes laminated crushing technology to effectively reduce liner wear, achieving a stable production capacity of 180-230 tons/hour. Customers have praised its "stable and reliable quality, maintaining performance like new after years of use." This equipment has also performed exceptionally well in the processing of quartz stone and wollastonite in the chemical industry. Its hydraulic system allows for rapid adjustment of the discharge opening size to accommodate varying process requirements, while its fully automatic control system significantly enhances the intelligent capabilities of the production line. Furthermore, the HPT series' multi-cylinder design dynamically balances crushing chamber pressure, reducing overload risks and making it particularly suitable for the high-intensity, continuous operations required by the metallurgical industry. In the processing of building materials and ceramic raw materials, the equipment's efficient fine crushing of materials such as dolomite and limestone further highlights its cross-industry adaptability.

Fully Hydraulic Control HPT100 Cone Crusher: Stable, Reliable, and Hassle-Free! Advantages

In terms of high-efficiency laminar crushing technology

The HPT hydraulic cone crusher achieves multi-angle continuous compression of materials within the crushing chamber through the coordinated design of a fixed main shaft and rotating eccentric sleeve. Its optimized eccentricity combined with motion parameters increases the compression stroke at the upper part of the moving cone, providing ample crushing pressure to the middle and lower sections of the chamber while preventing over-crushing of materials. This technology is particularly suited for high-hardness materials like iron ore and granite. In the Baotou magnetite project in Inner Mongolia, the HPT model served as the core equipment in the fine crushing stage, successfully reducing material to below 13mm. This significantly reduced energy consumption in subsequent grinding processes. The layer compression crushing principle enhances efficiency through mutual material compression, reducing needle and flake content in finished aggregates by 20%-30% while significantly increasing cubic particle proportions. This meets stringent aggregate shape requirements for high-grade concrete. Furthermore, by minimizing direct impact between metal components and materials, combined with a high-manganese steel crushing wall design, this technology enables the equipment to achieve outstanding performance—continuous operation for 8,000 hours without major repairs—in projects such as the Luanping Iron Ore Mine in Hebei Province.

Intelligent Hydraulic System

The HPT hydraulic cone crusher achieves precise production control through multi-cylinder hydraulic coordination technology. Its hydraulic system incorporates a triple mechanism of relief cylinders, locking cylinders, and thrust cylinders. This not only enables automatic pressure release during iron overload events but also allows millimeter-level discharge opening adjustment via hydraulic motor-driven fixed cone rotation. This technology is deeply integrated with the Siemens PLC control system, enabling real-time monitoring of critical parameters such as crushing chamber pressure and main shaft speed. It automatically adjusts the eccentric sleeve stroke to match different material characteristics, controlling product particle size fluctuations within ±0.5mm at the Dandong Gold Mine project in Liaoning. The hydraulic cavity-clearing system eliminates the need for shutdowns during material discharge, a common pain point in traditional equipment. Upon encountering non-crushable materials, the system completes pressure release and fault clearance within 3 seconds, achieving over 90% efficiency improvement compared to manual intervention. Additionally, the hydraulic lubrication system employs a labyrinth seal design, completely eliminating bearing wear caused by oil-water mixing. Combined with circulating oil cooling technology, it achieves zero lubrication system failures during continuous operations like granite processing in Macheng, Hubei. The system's intelligent diagnostics also use vibration sensors to provide early warnings of bearing abnormalities, boosting preventive maintenance efficiency by 40% and significantly reducing unplanned downtime risks.

Energy Efficiency and Environmental Design

The HPT hydraulic cone crusher achieves dual optimization of energy consumption and emissions through innovative technology. Its hydraulic system replaces traditional spring structures, boosting power transmission efficiency by 15%-20%. At the Luanping Iron Ore Project in Hebei, unit energy consumption dropped to 0.609 kW·h/t—a 43% reduction compared to conventional equipment. The optimized crushing chamber design, combined with the layer compression principle, forms a dense material layer within the chamber. This reduces ineffective crushing energy consumption while lowering dust generation by 60%. The equipment features a fully enclosed dust-proof design, with labyrinth seals at critical joints and negative pressure dust extraction interfaces. At the Xiangyang Pebble Sand Making Project in Hubei, it achieved an operational area PM10 concentration below 10mg/m³, meeting environmental standards. Additionally, the hydraulic system's stepless speed regulation automatically adjusts motor speed based on load, achieving 30% energy savings under low-load conditions. The application of high-manganese steel wear-resistant liners reduces metal wear rates by 50%, significantly decreasing solid waste generation. This design aligns with green mining construction requirements, assisting clients in passing environmental inspections at projects like the Baotou magnetite mine in Inner Mongolia while lowering operational costs.

Fully Hydraulic Control HPT100 Cone Crusher: Stable, Reliable, and Hassle-Free! Works Principle

The HPT hydraulic cone crusher employs the laminar crushing principle, achieving efficient and precise material crushing through a multi-cylinder hydraulic system. Its core operating mechanism can be divided into the following three key stages:

The motor drives the transmission shaft via a pulley or coupling, causing the eccentric sleeve to rotate. The rotational motion of the eccentric sleeve is transmitted through the main shaft to the moving cone, causing it to perform a swinging motion around a fixed point.

This design causes the gap between the crushing wall and the bowl liner to periodically change, creating a continuous squeezing action on the material. The bottom of the moving cone is supported by a single hydraulic piston, which not only bears the crushing load but also replaces the traditional spring relief device, simplifying the structure. After entering the crushing chamber, the material is subjected to multi-directional forces due to the swinging motion of the moving cone. Based on the layer compression theory, a stable material layer forms within the crushing chamber. Efficient crushing is achieved through the “material crushing material” layer compression effect. This crushing method produces more uniform final particle shapes, significantly increases the cubic content, and reduces needle and flake particles by 20%-30%. When the material meets discharge requirements, it falls through the gap created by the swinging crushing walls. Material that does not meet specifications continues to be crushed.

The multi-cylinder hydraulic system automatically adjusts the discharge opening via 10-16 hydraulic cylinders. When the oil pump supplies hydraulic fluid to the cylinders, the moving cone rises to reduce the discharge opening. When oil is released, the movable cone descends, enlarging the discharge opening. Should uncrushable foreign objects enter the crushing chamber, the hydraulic system automatically triggers protection: the accumulator piston compresses nitrogen, hydraulic oil enters the accumulator, and the movable cone descends to widen the discharge opening for foreign object ejection. After ejection, the hydraulic system automatically resets the movable cone to restore the original discharge opening position.

The equipment features a Siemens PLC and touchscreen system for real-time monitoring of parameters such as spindle speed and hydraulic pressure. Displacement sensors enable precise control of the discharge opening size with millimeter-level adjustment accuracy. The hydraulic lubrication system employs a labyrinth seal structure to effectively prevent dust contamination and extend the service life of critical components.

Fully Hydraulic Control HPT100 Cone Crusher: Stable, Reliable, and Hassle-Free! Technical Parameters

| Feed port size | 140 mm | Minimum discharge opening | 19 mm |

| Processing power | 20-40 mm | processing capacity | 45-140 t/h |