GP300 cone crusher for secondary crushing in mining and aggregates

The GP300 cone crusher is an efficient equipment suitable for medium and large-scale crushing needs, widely used in mining, sand and gravel production, and construction fields, especially suitable for high-capacity secondary and tertiary crushing operations. The device adopts a sturdy structural design and advanced crushing technology to ensure stable performance under high-intensity operation. Its crushing chamber and crushing force have been optimized to efficiently process hard rocks and ores, producing products with uniform particle size. GP300 is equipped with multiple optional cavity types, which can be flexibly adjusted according to different production needs to adapt to various crushing conditions. This model is operated through an advanced automatic control system, which facilitates real-time monitoring of equipment status and production efficiency, improving the accuracy of overall production management. Its design is not only easy to maintain, but also has low downtime, maximizing the service life and economic benefits of the equipment. In addition, GP300 has relatively low energy consumption, which can effectively save production costs and is suitable for long-term stable operation. In summary, the GP300 cone crusher, with its superior performance and versatile adaptability, is a highly favored equipment in medium and large-scale crushing operations, capable of providing customers with high-yield and high-quality crushing effects.

GP300 cone crusher for secondary crushing in mining and aggregates advantage

Efficient Design

The GP300 cone crusher adopts advanced crushing technology and optimized design, with high crushing force and strong processing capacity, which can meet the needs of large-scale crushing. Its crushing chamber has been scientifically designed to effectively improve production efficiency and perform well in medium and large-scale crushing operations.

Strong adaptability

GP300 is equipped with multiple cavity options, and users can flexibly adjust the cavity configuration according to different material hardness, particle size, and production needs to achieve the best crushing effect. This highly adaptable design enables the device to work efficiently in various application scenarios.

Stability and durability

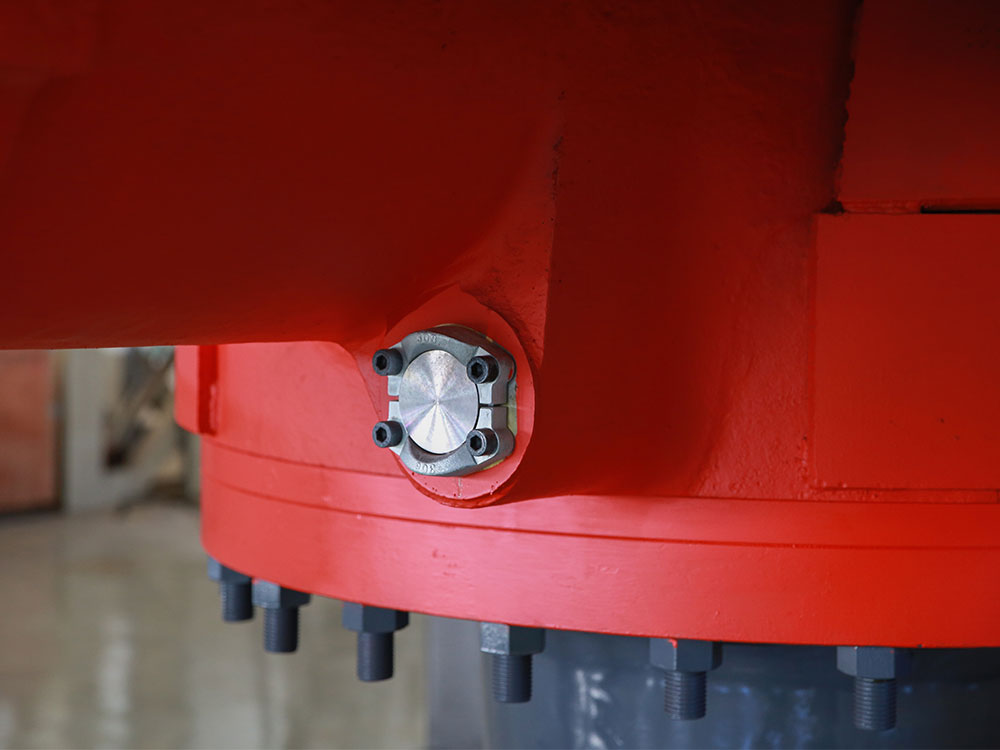

The GP300 cone crusher has a sturdy structure and is made of high-quality materials, ensuring stable operation of the equipment under long-term and high load conditions. Its durable component design significantly extends the service life of the equipment and reduces the cost of frequent replacement of parts.

Intelligent control system

The GP300 is equipped with an automated control system that can monitor the real-time operation status of the equipment and automatically adjust the crushing parameters to ensure crushing efficiency and product quality. At the same time, the system simplifies the operation process, allowing operators to easily manage equipment and improve work efficiency.

Convenient maintenance

The structural design of GP300 makes maintenance more convenient, maintenance and replacement of parts more time-saving and labor-saving, and reduces downtime. This easy to maintain feature not only improves the utilization rate of the equipment, but also reduces maintenance costs, ensuring that the equipment remains efficient throughout its entire service life.

Energy conservation and environmental protection

GP300 adopts energy-saving design, which reduces energy consumption during operation and helps to reduce production costs. In addition, its structural design reduces noise and dust pollution, meets environmental requirements, and is suitable for the sustainable development needs of modern mines and industrial enterprises.

High quality finished products

GP300 uses precise crushing control technology to achieve more uniform particle size and good particle shape in finished products, meeting the requirements of high-quality sand and gravel materials. It is widely used in engineering projects that require high particle size and quality of finished products.

GP300 cone crusher for secondary crushing in mining and aggregates working principle

The working principle of GP300 cone crusher mainly relies on laminated crushing technology, which crushes materials through the squeezing and shearing action between the fixed cone and the moving cone. After the device is started, the motor drives the transmission shaft to rotate, driving the movable cone to perform eccentric rotation within the fixed cone. The material is fed into the cavity from the top of the crusher, and as the moving cone rotates, the material is squeezed layer by layer between the two cones, thereby achieving crushing. During the crushing process, the eccentric rotation of the moving cone generates a strong crushing force, and the material is subjected to multiple compressions, bending, and shearing until it is crushed to the appropriate particle size and discharged from the discharge port. To ensure the uniformity of the discharge particle size, GP300 is equipped with an automatic adjustment device that can monitor and adjust the position of the moving cone in real time through the control system to maintain the appropriate gap and ensure that the discharge size meets the expected requirements. In addition, GP300 also adopts a hydraulic system, which facilitates the cleaning operation and overload protection of the equipment. When unbreakable materials enter the crushing chamber, the hydraulic system will automatically increase the pressure, lift the moving cone to avoid damaging the equipment, and then resume normal operation. This design greatly improves the reliability and safety of the equipment, reduces downtime caused by material blockage, and thus enhances overall production efficiency.

GP300 cone crusher for secondary crushing in mining and aggregates technical parameter

| Output | 100-450t/h | Feed port size | 220mm |

| Discharge size | < 220mm | Machine weight | 15t |

| Feed size | 15-50mm | Motor power | 200ke |

GP300 cone crusher for secondary crushing in mining and aggregates Case studies and customer reviews

In a large mining project in Egypt, the GP300 cone crusher was introduced for the secondary and tertiary crushing stages, significantly improving the production efficiency of the project. Due to the high hardness of the local ore, high requirements are placed on the durability and stability of the equipment, and GP300 performs outstandingly with its strong crushing ability and durability. This project adopts the GP300 multi cavity configuration, which flexibly adjusts the particle size of the discharge according to the characteristics of the ore, making the finished product particle size more uniform and meeting the demand for high-quality sand and gravel materials.

As a user of the GP300 cone crusher, I am very satisfied with its performance. In our project, this equipment not only provides strong crushing force, but also easily handles high hardness ores, fully meeting our production needs. Its multi cavity design is particularly practical, and we can flexibly adjust the discharge particle size according to production requirements, making the finished product more uniform and ideal in particle shape, fully meeting the project's requirements for high-quality sand and gravel

The automation control system of GP300 is also a major highlight. Through system monitoring and automatic adjustment, our operation has become simpler and more precise, reducing human intervention time and significantly improving production efficiency. In addition, the hydraulic cleaning function of the equipment is very reliable when encountering unbreakable objects, effectively avoiding the risk of shutdown and equipment damage. Overall, the GP300 cone crusher has exceeded our expectations in terms of performance, reliability, and ease of operation, making it a very reliable device. "