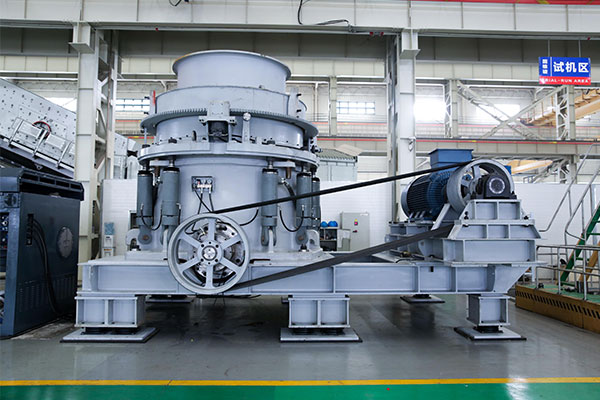

GP550 Cone Crusher, a crushing tool for mining industry

With its powerful crushing capacity and stable performance, GP550 cone crusher plays an important role in mining, aggregate and metallurgy industries. With its reasonable design and compact structure, it can flexibly adapt to various working environments and provide users with efficient and reliable crushing solutions.GP550 Cone Crusher adopts advanced crushing technology and optimised design, which has high efficient crushing capacity. It can easily handle ores and rocks of various hardnesses and grain sizes, crushing them quickly into the required grain sizes. Through precise adjustment and control, the GP550 Cone Crusher is able to produce finished products with uniform particle size and excellent quality. These finished products can show better performance and stability during subsequent processing and use.The GP550 Cone Crusher is equipped with an advanced intelligent control system, which is capable of real-time monitoring of the equipment's operating status and production data. The operator can intuitively understand the working condition of the equipment through the system interface and make automatic adjustments according to the actual situation to ensure the stable operation and efficient production of the equipment.The structure of the GP550 Cone Crusher is reasonably designed and easy to maintain and service. Its main components can be serviced from the top, greatly reducing maintenance costs and time. Meanwhile, the lubrication system and cooling system of the equipment are also well designed to ensure the long-term stable operation of the equipment.

GP550 Cone Crusher, a crushing tool for mining industry Applications

GP550 cone crusher is able to handle ores of various hardnesses, crushing them into the required particle size and providing high-quality raw materials for subsequent smelting and processing. In the mining and processing of metal ores, GP550 cone crusher plays a vital role.

In the aggregate industry, GP550 cone crusher is widely used in the production of construction aggregate and road aggregate. It is capable of crushing various rocks and minerals to produce high-quality aggregates to meet the demand for aggregates in construction, roads, bridges and other fields. These aggregates are characterised by uniform particle size, high strength and good durability, which can improve the quality and safety of construction projects.

In the metallurgical industry, GP550 Cone Crusher also plays an important role. It is capable of crushing various metallurgical raw materials and providing necessary raw materials for the smelting process. At the same time, due to its high crushing efficiency, low energy consumption and other characteristics, it can also reduce production costs and improve economic benefits.

GP550 Cone Crusher, a crushing tool for mining industry Advantages

Intelligent control

GP550 Cone Crusher is equipped with advanced intelligent control system, which can monitor the running status and production data of the equipment in real time. The operator can intuitively understand the working condition of the equipment through the system interface and make automatic adjustment according to the actual situation. This intelligent control not only improves the stability and reliability of the equipment, but also reduces the labour intensity of the operator.

High-efficiency crushing capacity

GP550 Cone Crusher adopts advanced crushing technology and optimised design, and has powerful crushing capacity. It can easily cope with aggregates of various hardnesses and particle sizes, and quickly crush them into the required particle size. This efficient crushing capacity not only increases the handling capacity of the plant, but also shortens the crushing cycle, thus improving the overall production efficiency.

Easy maintenance and repair

The GP550 Cone Crusher has a well-designed structure that is easy to maintain and service. Its main components can be serviced from the top, greatly reducing maintenance costs and time. Meanwhile, the lubrication system and cooling system of the machine are also well designed to ensure the long-term stable operation of the machine.

High Quality Finished Product Size

The GP550 Cone Crusher is capable of producing aggregates with uniform particle size and excellent quality through precise adjustment and control. These aggregates can show better performance and stability during subsequent processing and use. This is of great significance in ensuring the quality and safety of construction projects.

Strong adaptability

GP550 Cone Crusher can adapt to various specific production requirements. By changing parameters such as crushing chamber type, eccentric distance and horizontal shaft speed, as well as adopting different control methods, the GP550 Cone Crusher is able to flexibly cope with different types of aggregates and crushing requirements. This adaptability makes the GP550 Cone Crusher have a wider application prospect in the aggregate industry.

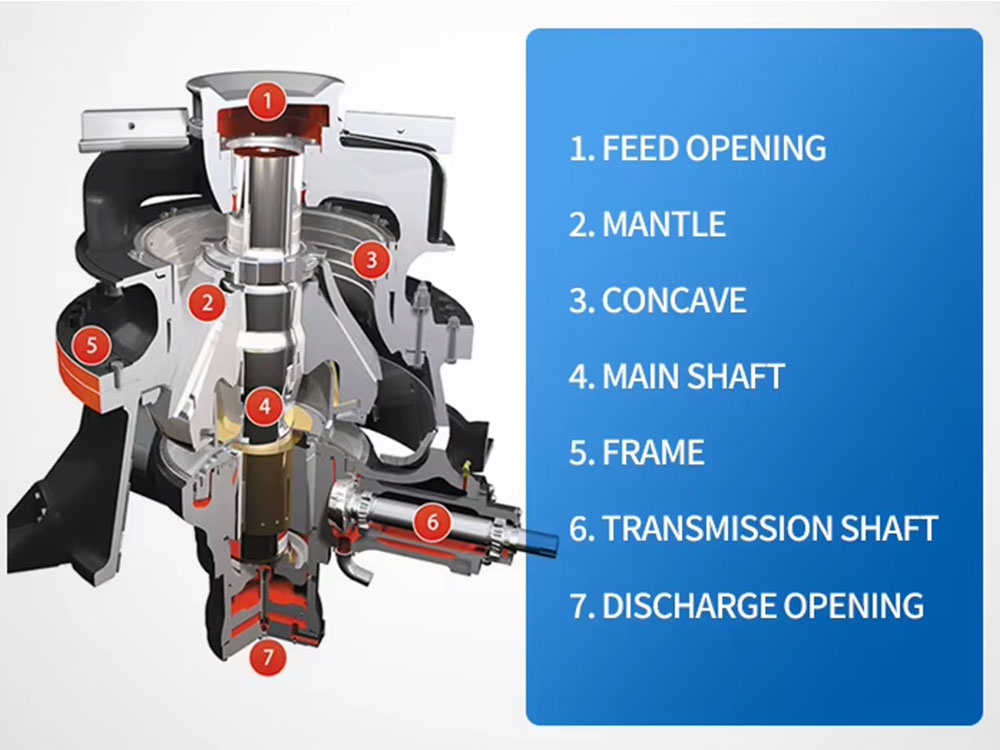

GP550 Cone Crusher, a crushing tool for mining industry Working Principle

When the material enters the crusher, the motor drives the eccentric bushing to rotate through the transmission device. This rotary motion makes the cone rotate around a fixed point under the force of the eccentric sleeve. As there is a certain gap between the moving cone and the static cone (also known as the fixed cone), the shape and size of the crushing chamber will change with the rotating swing of the moving cone.

When the moving cone is close to the static cone, the crushing chamber becomes narrow, and the material is subjected to strong extrusion and impact, thus realising crushing. When the cone leaves the static cone, the crushing chamber becomes spacious and the crushed material can be discharged from the bottom of the crushing chamber.

In this process, the materials in the crushing cavity are not only subject to the extrusion between the moving cone and the static cone, but also subject to the impact generated by the rotation of the moving cone, as well as the friction and shear effect between the materials. These combined forces make the material gradually be crushed into the required particle size.

In addition, the GP550 Cone Crusher is equipped with an advanced control system, which can monitor the operating status and production data of the machine in real time. The operator can adjust and control the equipment through the control system to ensure stable operation and efficient production.

Generally speaking, GP550 Cone Crusher is driven by the motor to rotate the eccentric shaft sleeve, which drives the dynamic cone to carry out the rotary oscillation movement, and makes the materials in the crushing chamber be gradually crushed by the action of various forces. This working principle makes GP550 Cone Crusher with high efficiency, stable and reliable performance, which plays an important role in aggregate industry.

GP550 Cone Crusher, a crushing tool for mining industry Technical Parameters

| Output | 500t/h | Stroke options | 40, 45 mm |

| Feed size | 235 mm | power | 250 - 400 kW |

| Wear parts | 10 profiles | Weight | 28 700 kg |